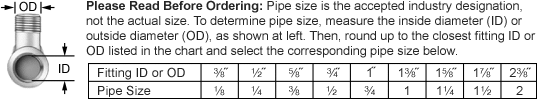

About Pipe Size and Spray Nozzles

More

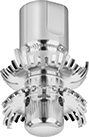

Clog-Resistant Tank-Washing Nozzles

Avoid clogs while rinsing tanks, drums, and small vessels. These nozzles have a unique internal and external design, so particles in liquid pass through instead of getting stuck. To effectively rinse down tanks and other containers, they spray in multiple directions. But, compared to standard tank-washing nozzles, they produce larger droplets and have a less precise spray pattern. These nozzles don't have any moving parts that will wear or need maintenance.

Brass nozzles have good corrosion resistance.

316 stainless steel nozzles are more chemical and corrosion resistant than brass nozzles.

Flow Rate, gpm | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| @ 20 psi | @ 40 psi | @ 60 psi | @ 400 psi | For Max. Tank Dia., ft. | Orifice Dia. | For Max. Particle Dia. | Overall Wd. | Max. Pressure, psi | Max. Temp., °F | Lg. | Each | |

180° Spray Angle | ||||||||||||

Brass | ||||||||||||

3/8 NPT Male | ||||||||||||

| 4.2 | 6 | 7.3 | 19 | 2 1/2 | 0.19" | 0.13" | 3/4" | 400 | 450° | 2 7/8" | 0000000 | 000000 |

| 7.5 | 10.6 | 13 | 33.5 | 5 | 0.25" | 0.13" | 3/4" | 400 | 450° | 2 15/16" | 0000000 | 00000 |

| 11.7 | 16.5 | 20.2 | 52.2 | 7 | 0.31" | 0.13" | 3/4" | 400 | 450° | 2 15/16" | 0000000 | 00000 |

316 Stainless Steel | ||||||||||||

3/8 NPT Male | ||||||||||||

| 4.2 | 6 | 7.3 | 19 | 2 1/2 | 0.19" | 0.13" | 3/4" | 400 | 800° | 2 7/8" | 00000000 | 000000 |

| 7.5 | 10.6 | 13 | 33.5 | 5 | 0.25" | 0.13" | 3/4" | 400 | 800° | 2 7/8" | 00000000 | 000000 |

| 11.7 | 16.5 | 20.2 | 52.2 | 7 | 0.31" | 0.13" | 3/4" | 400 | 800° | 2 7/8" | 00000000 | 000000 |

270° Spray Angle | ||||||||||||

Brass | ||||||||||||

3/8 NPT Male | ||||||||||||

| 4.2 | 6 | 7.3 | 19 | 2 1/2 | 0.19" | 0.13" | 3/4" | 400 | 450° | 3 5/8" | 0000000 | 000000 |

| 7.5 | 10.6 | 13 | 33.5 | 5 | 0.25" | 0.13" | 3/4" | 400 | 450° | 3 5/8" | 0000000 | 000000 |

| 11.7 | 16.5 | 20.2 | 52.2 | 7 | 0.31" | 0.13" | 3/4" | 400 | 450° | 3 5/8" | 0000000 | 000000 |

1/2 NPT Male | ||||||||||||

| 17 | 24.1 | 29.5 | 76.2 | 9 | 0.41" | 0.17" | 7/8" | 400 | 450° | 4 1/4" | 0000000 | 000000 |

316 Stainless Steel | ||||||||||||

3/8 NPT Male | ||||||||||||

| 4.2 | 6 | 7.3 | 19 | 2 1/2 | 0.19" | 0.13" | 3/4" | 400 | 800° | 3 5/8" | 00000000 | 000000 |

| 7.5 | 10.6 | 13 | 33.5 | 5 | 0.25" | 0.13" | 3/4" | 400 | 800° | 3 5/8" | 00000000 | 000000 |

| 11.7 | 16.5 | 20.2 | 52.2 | 7 | 0.31" | 0.13" | 3/4" | 400 | 800° | 3 5/8" | 00000000 | 000000 |

1/2 NPT Male | ||||||||||||

| 17 | 24.1 | 29.5 | 76.2 | 9 | 0.41" | 0.17" | 7/8" | 400 | 800° | 4 1/4" | 00000000 | 000000 |

360° Spray Angle | ||||||||||||

316 Stainless Steel | ||||||||||||

3/4 NPT Female | ||||||||||||

| 30 | 42 | Not Rated | Not Rated | 8 | 0.3" | 0.25" | 2 3/8" | 40 | 200° | 3 9/16" | 00000000 | 000000 |

1 NPT Female | ||||||||||||

| 70.6 | 100 | Not Rated | Not Rated | 10 | 0.25" | 0.3" | 2 3/8" | 40 | 200° | 4" | 00000000 | 000000 |

Rotating Tank-Washing Nozzles

By circulating their spray, these nozzles clean faster with more even coverage and less water than stationary tank-washing nozzles. The force of the liquid flowing through is what causes them to rotate, so the higher the pressure, the faster they will rotate. They spray in multiple directions to effectively rinse down tanks, drums, and small vessels.

316 stainless steel and PVDF nozzles have good resistance to chemicals and corrosion.

FDA-compliant nozzles can be used in the food industry.

Flow Rate, gpm | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| @ 20 psi | @ 40 psi | @ 60 psi | For Max. Tank Dia., ft. | Orifice Dia. | Overall Wd. | Lg. | Max. Pressure, psi | Max. Temp., °F | Spray Pattern | Spray Angle | Specifications Met | Environment | Each | ||

3/8 NPT Male | |||||||||||||||

| C | 5 | 7 | 8.5 | 5 | 0.09" | 13/16" | 2" | 70 | 250° | Multiple Flat Stream | 360° | FDA Compliant 21 CFR 110.40, FDA Compliant 21 CFR 177.1556, FDA Compliant 21 CFR 211.65 | Food Industry | 000000 | 0000000 |