Filter by

Mount Type

Mounting Location

System of Measurement

OD

For Suspending

Component

Weight Capacity

Clamping Distance

Bolt Material

Certification

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Base Mount Type

Color

Railing Clamps

For OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Inch | Metric, mm | For Pipe Size | For Thread Size | Bolt Material | Wt. Cap., lb. | Mount Type | Lg. | Wd. | Ht. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 11/16" to 1 5/16" | 17 to 33 | 3/8, 1/2, 3/4, 1 | 5/16"-18 | Zinc-Plated Steel | 125 | Clamp On | 2 1/2" | 5/8" | 3 7/8" | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 11/16" to 1 5/16" | 17 to 33 | 3/8, 1/2, 3/4, 1 | 5/16"-18 | 18-8 Stainless Steel | 125 | Clamp On | 2 1/2" | 5/8" | 3 7/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 1 5/16" to 2 3/8" | 33 to 60 | 1, 1 1/4, 1 1/2, 2 | 1/2"-13 | Zinc-Plated Steel | 600 | Clamp On | 3 7/8" | 1" | 6 3/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 1 5/16" to 2 3/8" | 33 to 60 | 1, 1 1/4, 1 1/2, 2 | 1/2"-13 | 18-8 Stainless Steel | 600 | Clamp On | 3 7/8" | 1" | 6 3/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 1 7/8" to 2" | 48 to 51 | 1 1/2 | 1/2"-13 | Zinc-Plated Steel | 600 | Clamp On | 6" | 1" | 4 3/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 1 7/8" to 2" | 48 to 51 | 1 1/2 | 1/2"-13 | Zinc-Plated Steel | 1,100 | Clamp On | 6" | 2" | 4 3/8" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 1 7/8" to 2" | 48 to 51 | 1 1/2 | 1/2"-13 | 18-8 Stainless Steel | 1,100 | Clamp On | 6" | 2" | 4 3/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 1 15/16" to 2" | 49 to 51 | 1 1/2 | — | Steel | 1,650 | Clamp On | 4 1/4" | 2" | 5 3/4" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Anodized Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 11/16" to 1 5/16" | 17 to 33 | 3/8, 1/2, 3/4, 1 | 5/16"-18 | Zinc-Plated Steel | 125 | Clamp On | 2 1/2" | 5/8" | 3 7/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 11/16" to 1 5/16" | 17 to 33 | 3/8, 1/2, 3/4, 1 | 5/16"-18 | 18-8 Stainless Steel | 125 | Clamp On | 2 1/2" | 5/8" | 3 7/8" | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 1 5/16" to 2 3/8" | 33 to 60 | 1, 1 1/4, 1 1/2, 2 | 1/2"-13 | Zinc-Plated Steel | 600 | Clamp On | 3 7/8" | 1" | 6 3/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 1 5/16" to 2 3/8" | 33 to 60 | 1, 1 1/4, 1 1/2, 2 | 1/2"-13 | 18-8 Stainless Steel | 600 | Clamp On | 3 7/8" | 1" | 6 3/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 1 7/8" to 2" | 48 to 51 | 1 1/2 | 1/2"-13 | Zinc-Plated Steel | 1,100 | Clamp On | 6" | 2" | 4 3/8" | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 1 7/8" to 2" | 48 to 51 | 1 1/2 | 1/2"-13 | 18-8 Stainless Steel | 1,100 | Clamp On | 6" | 2" | 4 3/8" | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| D | 1 11/16" to 1 7/8" | 43 to 48 | 1 1/4, 1 1/2 | 1/2"-13 | Zinc-Plated Steel | 1,100 | Clamp On | 4 1/4" | 2" | 5 3/4" | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

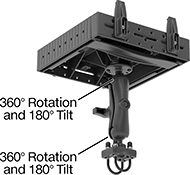

Ball-Grip Positioning Arms

|  |  |  |

Arm Built with Rotating Complete Arm with Ball, Rigid Connector, and Universal Mounting Plate | Clamp-On Pipe-Mount Bases, Style A | Clamp-On Pipe-Mount Bases, Style B | Clamp-On Pipe-Mount Bases, Style C |

Clamp-On Pipe-Mount Bases

|  |  |

Style A | Style B | Style C |

Base | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Clamping Distance Range | Ht. | Ball Dia. | Max. Load Cap., lb. | Material | Ball Material | Color | Lg. | Wd. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Rotate, Tilt, Side-to-Side, In/Out | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 5/8" to 1 1/8" | 4 3/16" | 1" | 1 | Plastic | Rubber | Black | — | 1 7/16" | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 5/8" to 1 1/8" | 4 1/4" | 1 1/2" | 3 | Plastic | Rubber | Black | — | 1 7/16" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 1" to 1 1/4" | 3" | 1 1/2" | 3 | Powder-Coated Aluminum | Rubber | Black | 2 3/8" | 7/8" | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 2" to 2 1/2" | 3 1/2" | 1 1/2" | 3 | Powder-Coated Aluminum | Rubber | Black | 4" | 2 1/8" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Threaded Hole Pipe-Mount Bases

Mounting | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ht. | Ball Dia. | Max. Load Cap., lb. | Material | Ball Material | Color | Base Dia. | No. of Holes | Hole Pipe Size | Hole Thread Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Rotate, Tilt, Side-to-Side, In/Out | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 1/4" | 1 1/2" | 3 | Aluminum | Rubber | Black | 1 1/4" | 1 | 1/2 | NPT | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

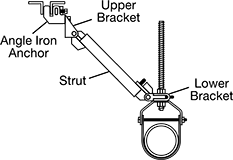

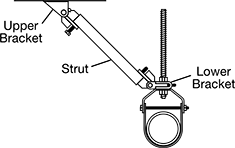

Seismic Bracing Mounts

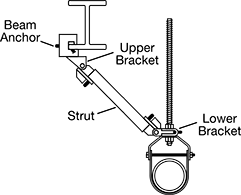

|  |

Angle Iron Mount | Ceiling Mount |

| |

Beam Mount |

Lower Bracket for Pipe and Strut Channel

For Suspending | For Pipe Schedule | For Strut Thk. | For Threaded Rod Dia. | Threaded Rod Included | Wd. | Lg. | Ht. | Material | Wt. Cap., lb. | No. of Set Screws Included | Certification | Includes | Each | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Threaded Rods | 40 | 7/64" | 3/8" to 5/8" | No | 2 1/4" | 5 1/8" | 1 13/16" | Zinc-Plated Steel | 1,000 | 2 | OSHPD Preapproved | Set Screws | 0000000 | 000000 |

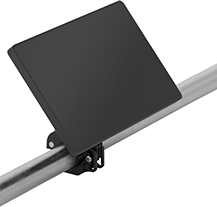

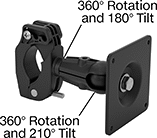

Pipe- and Bar-Mount Monitor Positioning Arms

Clamp-On Pipe Mount with Plate Attaching End

Projection | Base | Attaching End | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Display Ht. | Clamping Distance Range | Min. | Max. | Max. Load Cap., lb. | Material | Color | Lg. | Wd. | Range of Motion | Max. Tilt Range of Motion | Mounting Pattern Compatibility | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Rotate, Tilt, Side-to-Side, Up/Down, In/Out | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" to 6" | 1 1/4" to 2" | 4" | 7 3/4" | 10 | Powder-Coated Aluminum | Black | 3 3/4" | 1 1/4" | 360° | 210° | VESA 75 × 75 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Laptop Positioning Arms

Clamp-On Pipe Mount

Projection | Base | Attaching End | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Diag. Screen Size | Display Ht. | Clamping Distance Range | Min. | Max. | For Device Thickness | Max. Load Cap., lb. | Material | Color | Lg. | Wd. | Range of Motion | Max. Tilt Range of Motion | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Rotate, Tilt, Side-to-Side, Up/Down, In/Out | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 11" to 17 1/2" | 5 1/16" to 12 1/8" | 1" to 1 1/4" | 10" | 13 3/16" | 1/2" to 1 3/4" | 3 | Plastic | Black | 2 1/2" | 2 1/16" | 360° | 180° | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

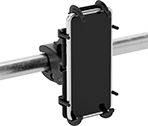

Mobile Device Positioning Arms

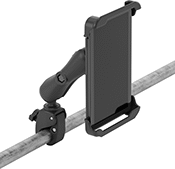

For Smartphones—Clamp-On Pipe Mount

Base | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Diag. Screen Size | Display Ht. | Clamping Distance Range | Max. Projection | Max. Load Cap. | Material | Color | Lg. | Wd. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Rotate, Tilt, Side-to-Side, Up/Down, In/Out | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5.5" to 6.9" | 0" to 1 5/8" | 5/8" to 1 1/8" | 5" | Not Rated | Plastic | Black | 3 9/16" | 1 1/8" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

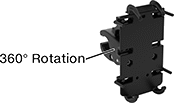

For Irregularly-Shaped Devices—Clamp-On Pipe Mount

Projection | For Device | Base | Attaching End | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Display Ht. | Clamping Distance Range | Min. | Max. | Wd. | Ht. | Dp. | Max. Load Cap., lb. | Material | Color | Lg. | Wd. | Range of Motion | Max. Tilt Range of Motion | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Rotate, Tilt, Side-to-Side, Up/Down, In/Out | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0" to 4 3/8" | 5/8" to 1 1/8" | 8 1/2" | 13 3/4" | 1 1/4" to 3 1/2" | 3 5/8" to 7 1/4" | 15/16" to 1 1/2" | 1 | Plastic | Black | 4 3/16" | 1 7/16" | 360° | 180° | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

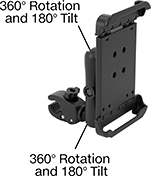

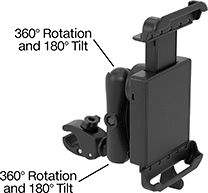

Tablet Positioning Arms

Clamp-On Pipe Mount

Projection | Base | Attaching End | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Diag. Screen Size | Display Ht. | Clamping Distance Range | Min. | Max. | Max. Load Cap., lb. | Material | Color | Lg. | Wd. | Range of Motion | Max. Tilt Range of Motion | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Rotate, Tilt, Side-to-Side, Up/Down, In/Out | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" to 8" | 0" to 8 1/16" | 5/8" to 1 1/8" | 2 11/16" | 10 11/16" | 3 | Plastic | Black | 4 7/8" | 1 7/16" | 360° | 180° | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9" to 10.5" | 0" to 8 1/16" | 5/8" to 1 1/8" | 2 13/16" | 10 7/8" | 3 | Plastic | Black | 4 7/8" | 1 7/16" | 360° | 180° | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

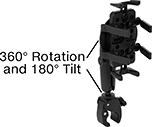

Vibration-Resistant Tablet Positioning Arms

Clamp-On Pipe Mount

|  |

Shown Installed |

Projection | Base | Attaching End | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Diag. Screen Size | Display Ht. | Clamping Distance Range | Min. | Max. | Max. Load Cap., lb. | Material | Color | Lg. | Wd. | Range of Motion | Max. Tilt Range of Motion | No. of Locks | Lock Type | No. of Keys Included | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Rotate, Tilt, Side-to-Side, Up/Down, In/Out | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" to 8" | 0" to 8" | 5/8" to 1 1/8" | 4 5/16" | 12 5/16" | 3 | Plastic | Black | 4 13/16" | 1 7/16" | 360° | 180° | 1 | Keyed | 2 | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9" to 10.5" | 0" to 8" | 5/8" to 1 1/8" | 4 7/16" | 12 1/2" | 3 | Plastic | Black | 4 13/16" | 1 7/16" | 360° | 180° | 1 | Keyed | 2 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||