How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

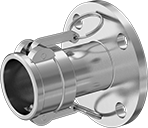

Low-Pressure Brass and Bronze Threaded Pipe Flanges

- For Use With: Air, Drinking Water, Natural Gas, Oil, Steam, Water

- Pressure Class: 150

- Specifications Met:

NPT: ASME B1.20.1, ASME B16.24, ASTM B584, NSF/ANSI 61

BSPT: ASTM B584, BS21 - Pipe Nipples and Pipe: Use Schedule 40 brass

- Fittings:

NPT: Use Class 125 brass

BSPT: Use Class 125 bronze

Also known as Pressure Class 150 flanges, these are designed for low-pressure applications. Bolt two same-size flanges together with a gasket (sold separately) to create an access point within a line. Flanges have good corrosion resistance. To adhere to safety standards for drinking water systems, use flanges that meet NSF/ANSI 61.

Bolt Hole | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Max. Pressure | Max. Steam Pressure | Material | Each | |

NPT | ||||||||||

| 1/2 | 3 1/2" | 1/2" | 5/8" | 4 | 2 3/8" | 225 psi @ 72° F | __ | Brass | 00000000 | 000000 |

| 3/4 | 3 7/8" | 1/2" | 5/8" | 4 | 2 3/4" | 225 psi @ 72° F | __ | Brass | 00000000 | 00000 |

| 1 | 4 1/4" | 1/2" | 5/8" | 4 | 3 1/8" | 225 psi @ 72° F | __ | Brass | 00000000 | 00000 |

| 1 1/4 | 4 5/8" | 1/2" | 5/8" | 4 | 3 1/2" | 225 psi @ 72° F | __ | Brass | 00000000 | 00000 |

| 1 1/2 | 5" | 1/2" | 5/8" | 4 | 3 7/8" | 225 psi @ 72° F | __ | Brass | 00000000 | 000000 |

| 2 | 6" | 5/8" | 3/4" | 4 | 4 3/4" | 225 psi @ 72° F | __ | Brass | 00000000 | 000000 |

| 2 1/2 | 7" | 5/8" | 3/4" | 4 | 5 1/2" | 225 psi @ 72° F | __ | Brass | 00000000 | 000000 |

| 3 | 7 1/2" | 5/8" | 3/4" | 4 | 6" | 225 psi @ 72° F | __ | Brass | 00000000 | 000000 |

| 4 | 9" | 5/8" | 3/4" | 8 | 7 1/2" | 225 psi @ 72° F | __ | Brass | 00000000 | 000000 |

BSPT | ||||||||||

| 1/2 | 3 1/2" | 1/2" | 5/8" | 4 | 2 3/8" | 200 psi @ 72° F | 125 psi @ 400° F | Bronze | 00000000 | 00000 |

| 3/4 | 3 7/8" | 1/2" | 5/8" | 4 | 2 3/4" | 200 psi @ 72° F | 125 psi @ 400° F | Bronze | 00000000 | 00000 |

| 1 | 4 1/4" | 1/2" | 5/8" | 4 | 3 1/8" | 200 psi @ 72° F | 125 psi @ 400° F | Bronze | 00000000 | 000000 |

| 1 1/2 | 5" | 1/2" | 5/8" | 4 | 3 7/8" | 200 psi @ 72° F | 125 psi @ 400° F | Bronze | 00000000 | 000000 |

| 2 | 6" | 5/8" | 3/4" | 4 | 4 3/4" | 200 psi @ 72° F | 125 psi @ 400° F | Bronze | 00000000 | 000000 |

Low-Pressure Brass and Bronze Threaded Pipe Fittings

Use these fittings in low-pressure flow applications. They have good corrosion resistance. Fittings rated for use with drinking water meet NSF/ANSI 61 safety standards.

Locknuts thread onto the male end of a fitting to provide extra holding power so the fitting won’t loosen from vibration.

NPSL (National Pipe Straight Locknut) threads are compatible with NPT threads.

- For Use With: See table

- Pressure Class: See table

- Specifications Met: See table

- Pipe Nipples and Pipe: See table

- Flanges: See table

For Pipe | For Flange | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Max. Pressure | Pressure Class | Material | Schedule | Material | Class | Material | For Use With | Specifications Met | Each | |

NPSL Female | |||||||||||

| 1/8 | 200 psi @ 72° F | 125 | Brass | 40 | Brass | 150 | Brass | Air, Drinking Water, Natural Gas, Oil | ASME B1.20.1, ASME B16.15, ASTM A584, NSF/ANSI 61 | 00000000 | 00000 |

| 1/4 | 200 psi @ 72° F | 125 | Brass | 40 | Brass | 150 | Brass | Air, Drinking Water, Natural Gas, Oil | ASME B1.20.1, ASME B16.15, ASTM A584, NSF/ANSI 61 | 00000000 | 0000 |

| 3/8 | 200 psi @ 72° F | 125 | Brass | 40 | Brass | 150 | Brass | Air, Drinking Water, Natural Gas, Oil | ASME B1.20.1, ASME B16.15, ASTM A584, NSF/ANSI 61 | 00000000 | 0000 |

| 1/2 | 200 psi @ 72° F | 125 | Brass | 40 | Brass | 150 | Brass | Air, Drinking Water, Natural Gas, Oil | ASME B1.20.1, ASME B16.15, ASTM A584, NSF/ANSI 61 | 00000000 | 0000 |

| 3/4 | 200 psi @ 72° F | 125 | Brass | 40 | Brass | 150 | Brass | Air, Drinking Water, Natural Gas, Oil | ASME B1.20.1, ASME B16.15, ASTM A584, NSF/ANSI 61 | 00000000 | 0000 |

| 1 | 200 psi @ 72° F | 125 | Brass | 40 | Brass | 150 | Brass | Air, Drinking Water, Natural Gas, Oil | ASME B1.20.1, ASME B16.15, ASTM A584, NSF/ANSI 61 | 00000000 | 00000 |

| 1 1/4 | 200 psi @ 72° F | 125 | Brass | 40 | Brass | 150 | Brass | Air, Drinking Water, Natural Gas, Oil | ASME B1.20.1, ASME B16.15, ASTM A584, NSF/ANSI 61 | 00000000 | 00000 |

| 1 1/2 | 200 psi @ 72° F | 125 | Brass | 40 | Brass | 150 | Brass | Air, Drinking Water, Natural Gas, Oil | ASME B1.20.1, ASME B16.15, ASTM A584, NSF/ANSI 61 | 00000000 | 00000 |

| 2 | 200 psi @ 72° F | 125 | Brass | 40 | Brass | 150 | Brass | Air, Drinking Water, Natural Gas, Oil | ASME B1.20.1, ASME B16.15, ASTM A584, NSF/ANSI 61 | 00000000 | 00000 |

| 2 1/2 | 200 psi @ 72° F | 125 | Brass | 40 | Brass | 150 | Brass | Air, Natural Gas, Oil | ASME B16.15 | 00000000 | 00000 |

| 3 | 200 psi @ 72° F | 125 | Brass | 40 | Brass | 150 | Brass | Air, Natural Gas, Oil | ASME B16.15 | 00000000 | 00000 |

Brass and Bronze Unthreaded Pipe Flanges

Bolt these flanges to equipment or to another same-size, flat-surface flange with a gasket (sold separately). They have good corrosion resistance.

Cap flanges are also known as blind flanges.

- For Use With: Air, Argon, Natural Gas, Nitrogen Gas, Oil, Oxygen, Water

- Pressure Class : 150

- Specifications Met: ASME B16.24

- Pipe Nipples and Pipe: Use Schedule 40 brass

Press-Connect Fittings for Copper Tubing

- For Use With: Drinking Water

- Maximum Pressure: Fittings compatible with Viega ProPress or Viega ProPress XL-C: 200 psi @ 72° F

Fittings compatible with Viega Pex or Viega PureFlow Press: 100 psi @ 72° F - Temperature Range: 0° to 250° F

- Tubing: Fittings compatible with Viega ProPress or Viega ProPress XL-C: Use with K, M, L copper

Fittings compatible with Viega Pex or Viega PureFlow Press: Use with hard polyethylene plastic - Specifications Met: See table

Crimp these fittings to copper tubing with a crimping tool (sold separately). An O-ring on the inside of the fitting creates a leak-tight connection that doesn’t require heat or soldering. They are comparable to Viega ProPress fittings. Fittings have good corrosion resistance. They meet NSF/ANSI safety standards for use with drinking water systems.

Copper tube size is the accepted designation of the copper tubing industry, not the actual tube OD.

Straight adapters with flanged end bolt to equipment or other flanged connections found on pumps and valves to create a convenient access point.

Bolt Hole | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Copper Tube Size | For Tube OD | Pipe Size | Flange OD | Bolt Circle Dia. | Dia. | No. of | For Bolt Dia. | Bolts Included | Lg. | Material | Flange Material | Compatible With | Specifications Met | Each | |

| 1 | 1 1/8" | 1 | 4 21/64" | 3 7/64" | 5/8" | 4 | 1/2" | No | 2 49/64" | Bronze | Powder-Coated Steel | Viega ProPress | ASME B16.51, ASME B31.1, ASME B31.3, ASME B31.9, FM Approved, NSF/ANSI 61 | 00000000 | 0000000 |

| 1 1/4 | 1 3/8" | 1 1/4 | 4 17/32" | 3 1/2" | 5/8" | 4 | 1/2" | No | 2 49/64" | Bronze | Powder-Coated Steel | Viega ProPress | ASME B16.51, ASME B31.1, ASME B31.3, ASME B31.9, FM Approved, NSF/ANSI 61 | 00000000 | 000000 |

| 1 1/2 | 1 5/8" | 1 1/2 | 4 59/64" | 3 55/64" | 5/8" | 4 | 1/2" | No | 3 1/16" | Bronze | Powder-Coated Steel | Viega ProPress | ASME B16.51, ASME B31.1, ASME B31.3, ASME B31.9, FM Approved, NSF/ANSI 61 | 00000000 | 000000 |

| 2 | 2 1/8" | 2 | 5 29/32" | 4 49/64" | 3/4" | 4 | 5/8" | No | 3 21/32" | Bronze | Powder-Coated Steel | Viega ProPress | ASME B16.51, ASME B31.1, ASME B31.3, ASME B31.9, FM Approved, NSF/ANSI 61 | 00000000 | 000000 |

Jaws for copper tube sizes ½ to 2 fit directly into the included crimping tool.

Battery | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Copper Tube Size | For Tube OD | Voltage | No. Included | Cap., amp-hrs. | Battery Charger Included | Battery Charging Time, min. | Compatible With | Specifications Met | Each | |

| 1/2, 3/4, 1, 1 1/4, 1 1/2, 2 | 5/8", 7/8", 1 1/8", 1 3/8", 1 5/8", 2 1/8" | 18V DC | 2 | 3 | Yes | 39 | Viega ProPress | EMC 2011/65/EU, EMC 2014/30/EU, IEC 62841-1, UL 62841-1 | 00000000 | 000000000 |

Metal Cam-and-Groove Hose Couplings for Chemicals and Petroleum

Made of metal, these couplings have better durability than plastic cam-and-groove couplings. A complete coupling consists of a plug and a socket (both sold separately) that allow you to quickly connect and disconnect medium-to large-diameter hose lines. To connect, insert the plug into the socket and press the levers down. The levers fit snugly into the groove on the plug’s body and force the plug against the gasket to form a tight seal. To disconnect, lift both levers and pull out the plug. Couplings are compatible with Andrews, Dixon, Ever-Tite, and PT cam-and-groove couplings.

Aluminum fittings are lighter in weight than 316 stainless steel fittings. They have good corrosion resistance.

Note: To ensure a correct fit, make sure that the plug and socket have the same coupling size.

Warning: Relieve all pressure before disconnecting the couplings. Do not use cam-and-groove couplings with compressed air or gas.

- For Use With: Citric Acid, Diesel Fuel, Gasoline, Hydraulic Fluid

- Maximum Pressure: See table

- Temperature Range: -65° to 250° F

- Compatible With: Andrews Cam-and-Groove, Dixon Cam-and-Groove, Ever-Tite Cam-and-Groove, PT Coupling Cam-and-Groove

- Specifications Met:

Aluminum: ASME B16.24, Fed. Spec. A-A-59326

316 Stainless Steel: ASME B16.5, Fed. Spec. A-A-59326

Sockets with flanged end are also known as PFC couplers. Bolt the flanged end to another same-size flange with a gasket.

Sockets | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Bolt Hole | Replacement Gaskets | Replacement Levers | Protective Plugs | |||||||||||||||||

| Coupling Size | Socket ID | Pipe Size | Dash Size | Flange OD | Pressure Class | No. of Levers | Max. Pressure | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Each | Pkg. Qty. | Pkg. | Each | Each | ||||

Aluminum with Brass Levers and Zinc-Plated Steel Pull Rings | ||||||||||||||||||||

Flat Flanged Connection Surface | ||||||||||||||||||||

| 2 | 2 1/2" | 2 | 32 | 6" | 150 | 2 | 250 psi @ 72° F | 5/8" | 3/4" | 4 | 4 3/4" | 000000000 | 0000000 | 10 | 0000000 | 00000 | 000000000 | 00000 | 0000000 | 000000 |

| 3 | 3 5/8" | 3 | 48 | 7 1/2" | 150 | 2 | 200 psi @ 72° F | 5/8" | 3/4" | 4 | 6" | 000000000 | 000000 | 10 | 0000000 | 00000 | 000000000 | 0000 | 0000000 | 00000 |

| 4 | 4 3/4" | 4 | 64 | 9" | 150 | 2 | 150 psi @ 72° F | 5/8" | 3/4" | 8 | 7 1/2" | 000000000 | 000000 | 10 | 0000000 | 00000 | 000000000 | 0000 | 0000000 | 00000 |

| 6 | 6 15/16" | 6 | 96 | 11" | 150 | 2 | 75 psi @ 72° F | 3/4" | 7/8" | 8 | 9 1/2" | 000000000 | 000000 | 5 | 0000000 | 00000 | 000000000 | 00000 | 000000 | 00 |