Matching Flow Diagrams to Replace an Air Directional Control Valve

More

Choosing an Air Directional Control Valve

More

About Precision Flow-Adjustment Valves

More

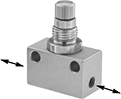

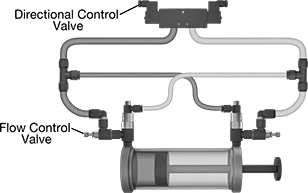

About Flow Control Valves

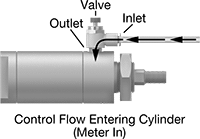

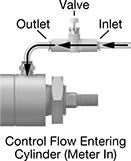

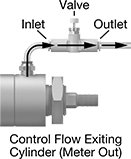

Also known as cylinder speed controls, flow control valves let you control the extension or retraction speed of your air cylinder. They regulate airflow as it passes from the valve's inlet to its outlet. Air flows freely in the opposite direction.

More

Easy-Set Threaded Precision Flow-Adjustment Valves

- Valve Type: Needle

- For Use With: Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon

- Seal Material: Fluoroelastomer Rubber

The color-coded threads and numerical markings on these valves ensure consistent and repeatable settings. One full revolution of the handle reveals a new color to indicate the set point. Turn the handle to adjust flow in small increments for metering, sampling, and other applications requiring fine flow control. Valves have metal-to-metal seats that resist temperature fluctuations.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | Seal Material | End-to-End Lg. | Each | |

Brass Body | |||||||

|---|---|---|---|---|---|---|---|

BSPP Female × BSPP Female | |||||||

| 1/4 | 0.51 | 2000 psi @ 400° F | -15° to 400° | Fluoroelastomer Rubber | 1 3/4" | 0000000 | 000000 |

| 1/4 | 0.53 | 2000 psi @ 190° F | -15° to 200° | Fluoroelastomer Rubber | 2 1/2" | 0000000 | 00000 |

| 3/8 | 0.92 | 2000 psi @ 400° F | -15° to 400° | Fluoroelastomer Rubber | 2 1/16" | 0000000 | 00000 |

| 1/2 | 0.93 | 2000 psi @ 190° F | -15° to 200° | Fluoroelastomer Rubber | 3 7/16" | 0000000 | 000000 |

BSPT Female × BSPT Female | |||||||

| 1/8 | 0.25 | 2000 psi @ 400° F | -15° to 400° | Fluoroelastomer Rubber | 1 7/16" | 0000000 | 00000 |

| 1/4 | 0.51 | 2000 psi @ 400° F | -15° to 400° | Fluoroelastomer Rubber | 1 3/4" | 0000000 | 00000 |

| 3/8 | 0.92 | 2000 psi @ 400° F | -15° to 400° | Fluoroelastomer Rubber | 2 1/16" | 0000000 | 00000 |

Steel Body | |||||||

BSPT Female × BSPT Female | |||||||

| 3/8 | 0.92 | 5000 psi @ 400° F | -15° to 400° | Fluoroelastomer Rubber | 2 1/16" | 0000000 | 00000 |

| 1/2 | 0.93 | 5000 psi @ 190° F | -15° to 200° | Fluoroelastomer Rubber | 3 7/16" | 0000000 | 000000 |

| 3/4 | 1.43 | 5000 psi @ 190° F | -15° to 200° | Fluoroelastomer Rubber | 3 3/4" | 0000000 | 000000 |

Threaded Precision Flow-Adjustment Valves

Also known as needle valves, these adjust flow in small increments for metering, sampling, and other applications requiring fine flow control. Turn the handle to adjust flow. All valves have metal-to-metal seats that resist temperature fluctuations.

Locking handles have a nut to prevent accidental flow adjustment.

Internal check valves actuate when the pressure changes to stop flow from the controlled direction and allow free flow in the opposite direction. Valves with an internal check valve are often used to control the speed of air cylinders and air-powered motors.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

- Valve Type: Needle

- For Use With: Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon

- Seal Material: Fluoroelastomer Rubber/PTFE Plastic

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | End-to-End Lg. | Each | |

Brass Body with Locking Knob Handle | ||||||

|---|---|---|---|---|---|---|

| 1/8 | 0.2 | 2000 psi @ 400° F | -15° to 400° | 1 1/2" | 0000000 | 000000 |

| 1/4 | 0.43 | 2000 psi @ 400° F | -15° to 400° | 2" | 0000000 | 00000 |

| 3/8 | 0.78 | 2000 psi @ 400° F | -15° to 400° | 2 1/4" | 0000000 | 00000 |

Brass Body with Locking Knob Handle and Internal Check Valve | ||||||

| 1/4 | 0.54 | 2000 psi @ 400° F | -15° to 400° | 2 3/8" | 0000000 | 00000 |

| 3/8 | 0.83 | 2000 psi @ 400° F | -15° to 400° | 2 3/4" | 0000000 | 00000 |

High-Pressure Threaded Precision Flow-Adjustment Valves

Often used in hydraulic and compressed air systems, these valves can withstand at least 6,000 psi. Turn the handle to adjust flow in small increments for metering, sampling, and other applications requiring fine flow control.

316 stainless steel valves are more corrosion resistant than brass and steel valves.

Metal-to-metal seats resist temperature fluctuations.

Valves with packing have a nut that can be tightened to compress the packing if it leaks.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

- Valve Type: Needle

- Seal Material: See table

- For Use With: See table

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | Packing Material | Port-to-Port Lg. | For Use With | Each | ||

BSPP Female × BSPP Female | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| N | 1/8 | 0.4 | 6000 psi @ 100° F | -100° to 500° | PTFE Plastic | 1 9/16" | Oil, Acetone, Air, Ammonia, Diesel Fuel | 0000000 | 000000 |

| N | 1/4 | 0.4 | 6000 psi @ 100° F | -100° to 500° | PTFE Plastic | 1 7/8" | Oil, Acetone, Air, Ammonia, Diesel Fuel | 0000000 | 00000 |

| N | 1/4 | 0.4 | 10000 psi @ 100° F | -100° to 500° | PTFE Plastic | 1 7/8" | Oil, Acetone, Air, Ammonia, Diesel Fuel | 0000000 | 00000 |

| N | 3/8 | 0.4 | 6000 psi @ 100° F | -100° to 500° | PTFE Plastic | 1 7/8" | Oil, Acetone, Air, Ammonia, Diesel Fuel | 0000000 | 00000 |

| N | 1/2 | 0.46 | 6000 psi @ 100° F | -100° to 500° | PTFE Plastic | 2 11/16" | Oil, Acetone, Air, Ammonia, Diesel Fuel | 0000000 | 00000 |

| N | 1/2 | 0.46 | 10000 psi @ 100° F | -100° to 500° | PTFE Plastic | 2 11/16" | Oil, Acetone, Air, Ammonia, Diesel Fuel | 0000000 | 00000 |

| N | 3/4 | 0.75 | 6000 psi @ 100° F | -100° to 500° | PTFE Plastic | 2 11/16" | Oil, Acetone, Air, Ammonia, Diesel Fuel | 0000000 | 00000 |

BSPP Male × BSPP Female | |||||||||

| P | 1/4 | 0.28 | 6000 psi @ 100° F | -100° to 500° | PTFE Plastic | 1 15/16" | Oil, Acetone, Air, Ammonia, Diesel Fuel | 0000000 | 00000 |

BSPT Female × BSPT Female | |||||||||

| N | 1/8 | 0.4 | 6000 psi @ 100° F | -100° to 500° | PTFE Plastic | 1 9/16" | Oil, Acetone, Air, Ammonia, Diesel Fuel | 0000000 | 00000 |

| N | 1/2 | 0.46 | 6000 psi @ 100° F | -100° to 500° | PTFE Plastic | 2 11/16" | Oil, Acetone, Air, Ammonia, Diesel Fuel | 0000000 | 00000 |

BSPT Male × BSPT Female | |||||||||

| P | 1/2 | 0.46 | 6000 psi @ 100° F | -100° to 500° | PTFE Plastic | 2 11/16" | Oil, Acetone, Air, Ammonia, Diesel Fuel | 0000000 | 00000 |

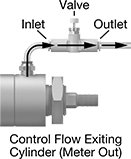

Elbow Air Flow Control Valves

Push-to-Connect

Female Outlet with Plastic Body

Push-to-Connect Female

Outlet with Pressure-Release Button

Female Inlet ×

Threaded Male Outlet

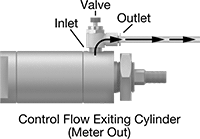

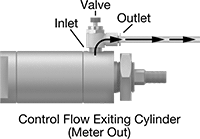

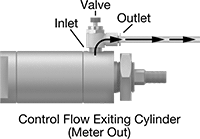

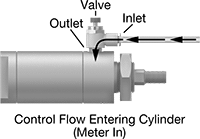

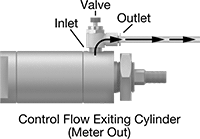

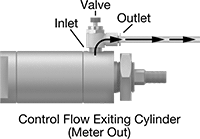

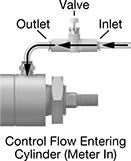

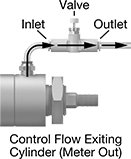

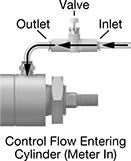

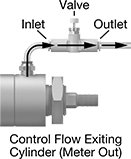

Meter out valves control flow as it exits the cylinder. Meter in valves control flow as it enters the cylinder.

Valves with push-to-connect ports are for use with plastic or soft metal tubing. Insert tubing into the port.

Valves with a pressure-release button allow you to exhaust any trapped air pressure from the system after shut down.

Inlet | Outlet | Flow Rate | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Flow Control Type | ISO Designation | Flow Adjustment Mechanism | Inlet Pipe Size | For Outlet Tube OD, mm | Flow Coefficient (Cv) | Min. @ 73 psi | Max. @ 73 psi | Min. @ 100 psi | Max. @ 100 psi | Max. Pressure, psi | Temp. Range, °F | Each | |

PBT Plastic Body | |||||||||||||

| Exiting Cylinder | Meter Out | Dial | 1/8 | 4 | 0.15 | __ | __ | 0 scfm | 4.8 scfm | 150 | 0° to 175° | 000000000 | 000000 |

| Exiting Cylinder | Meter Out | Dial | 1/8 | 6 | 0.19 | __ | __ | 0 scfm | 6.1 scfm | 150 | 0° to 175° | 000000000 | 00000 |

| Exiting Cylinder | Meter Out | Dial | 1/8 | 8 | 0.19 | __ | __ | 0 scfm | 6.1 scfm | 150 | 0° to 175° | 000000000 | 00000 |

| Exiting Cylinder | Meter Out | Dial | 1/4 | 4 | 0.22 | __ | __ | 0 scfm | 7 scfm | 150 | 0° to 175° | 000000000 | 00000 |

| Exiting Cylinder | Meter Out | Dial | 1/4 | 6 | 0.33 | __ | __ | 0 scfm | 10.5 scfm | 150 | 0° to 175° | 000000000 | 00000 |

| Exiting Cylinder | Meter Out | Dial | 1/4 | 8 | 0.39 | __ | __ | 0 scfm | 12.5 scfm | 150 | 0° to 175° | 000000000 | 00000 |

| Exiting Cylinder | Meter Out | Dial | 3/8 | 6 | 0.56 | __ | __ | 0 scfm | 17.9 scfm | 150 | 0° to 175° | 000000000 | 00000 |

| Exiting Cylinder | Meter Out | Dial | 3/8 | 8 | 0.67 | __ | __ | 0 scfm | 21.4 scfm | 150 | 0° to 175° | 000000000 | 00000 |

| Exiting Cylinder | Meter Out | Dial | 1/2 | 10 | 1.33 | __ | __ | 0 scfm | 42.5 scfm | 150 | 0° to 175° | 00000000 | 00000 |

PBT Plastic Body with Pressure-Release Button | |||||||||||||

| Exiting Cylinder | Meter Out | Dial | 1/8 | 6 | 0.2 | 0 scfm | 9.28 scfm | __ | __ | 145 | 25° to 140° | 000000000 | 00000 |

| Exiting Cylinder | Meter Out | Dial | 1/8 | 8 | 0.2 | 0 scfm | 9.28 scfm | __ | __ | 145 | 25° to 140° | 000000000 | 00000 |

| Exiting Cylinder | Meter Out | Dial | 1/4 | 6 | 0.2 | 0 scfm | 9.28 scfm | __ | __ | 145 | 25° to 140° | 000000000 | 00000 |

| Exiting Cylinder | Meter Out | Dial | 1/4 | 8 | 0.2 | 0 scfm | 9.28 scfm | __ | __ | 145 | 25° to 140° | 000000000 | 00000 |

Inlet | Outlet | Flow Rate @ 100 psi | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Flow Control Type | ISO Designation | Flow Adjustment Mechanism | Inlet Pipe Size | Outlet Pipe Size | Flow Coefficient (Cv) | Min. | Max. | Max. Pressure, psi | Temp. Range, °F | Each | |

Zinc Body | |||||||||||

| Exiting Cylinder | Meter Out | Dial | 1/8 | 1/8 | 0.34 | Not Rated | 12.6 scfm | 145 | 15° to 140° | 0000000 | 000000 |

| Exiting Cylinder | Meter Out | Dial | 1/4 | 1/4 | 0.61 | Not Rated | 22.6 scfm | 145 | 15° to 140° | 0000000 | 00000 |

Inlet | Outlet | Flow Rate @ 100 psi | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Flow Control Type | ISO Designation | Flow Adjustment Mechanism | For Inlet Tube OD, mm | Outlet Pipe Size | Flow Coefficient (Cv) | Min. | Max. | Max. Pressure, psi | Temp. Range, °F | Each | |

PBT Plastic Body | |||||||||||

| Entering Cylinder | Meter In | Dial | 4 | 1/4 | 0.22 | 0 scfm | 7 scfm | 150 | 0° to 175° | 000000000 | 000000 |

| Entering Cylinder | Meter In | Dial | 4 | 1/8 | 0.15 | 0 scfm | 4.8 scfm | 150 | 0° to 175° | 000000000 | 00000 |

| Entering Cylinder | Meter In | Dial | 6 | 1/4 | 0.33 | 0 scfm | 10.5 scfm | 150 | 0° to 175° | 000000000 | 00000 |

| Entering Cylinder | Meter In | Dial | 6 | 1/8 | 0.19 | 0 scfm | 6.1 scfm | 150 | 0° to 175° | 000000000 | 00000 |

| Entering Cylinder | Meter In | Dial | 6 | 3/8 | 0.56 | 0 scfm | 17.9 scfm | 150 | 0° to 175° | 000000000 | 00000 |

| Entering Cylinder | Meter In | Dial | 8 | 1/4 | 0.39 | 0 scfm | 12.5 scfm | 150 | 0° to 175° | 000000000 | 00000 |

| Entering Cylinder | Meter In | Dial | 8 | 1/8 | 0.19 | 0 scfm | 6.1 scfm | 150 | 0° to 175° | 000000000 | 00000 |

| Entering Cylinder | Meter In | Dial | 8 | 3/8 | 0.67 | 0 scfm | 21.4 scfm | 150 | 0° to 175° | 000000000 | 00000 |

| Entering Cylinder | Meter In | Dial | 10 | 1/2 | 1.33 | 0 scfm | 42.5 scfm | 150 | 0° to 175° | 00000000 | 00000 |

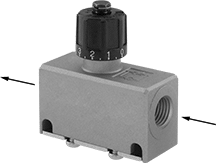

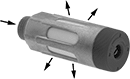

Inline Air Flow Control Valves with Flow Indicator

A flow indicator on these valves provides a relative measure of the air flowing through the valve, from off to full volume, similar to the volume dial on a speaker. The indicator’s numeric increments make it easy to set the valve to the same flow rate with each use. They adjust the volume of airflow to control the speed of air-powered equipment. Valves control flow in one direction as air moves from the inlet to the outlet. Air flows freely in the opposite direction. Typically, valves are installed to control flow as it exits the cylinder (meter out), but they may also be installed to control flow as it enters the cylinder (meter in). Designed to be mounted inline, they can be installed in an easy-to-reach location along your line. For the best control, mount them as close to the cylinder as possible to minimize the length of tubing or piping between the cylinder and the valve.

Flow coefficient (Cv) is a measurement that indicates how much airflow can pass through a valve.

Flow Rate @ 73 psi | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Inlet Pipe Size | Outlet Pipe Size | Flow Coefficient (Cv) | Min. | Max. | Max. Pressure, psi | Temp. Range, °F | Flow Adjustment Mechanism | Flow Control Type (ISO Designation) | Each | |

Aluminum Body | ||||||||||

| 1/4 | 1/4 | 0.82 | 0 scfm | 32.4 scfm | 145 | 25° to 140° | Dial | Exiting Cylinder (Meter Out), Entering Cylinder (Meter In) | 00000000 | 000000 |

| 3/8 | 3/8 | 0.82 | 0 scfm | 32.4 scfm | 145 | 25° to 140° | Dial | Exiting Cylinder (Meter Out), Entering Cylinder (Meter In) | 00000000 | 00000 |

Elbow Air Flow Control Valves with Flow Indicator

A flow indicator on these valves provides a relative measure of the air flowing through the valve, from off to full volume, similar to the volume dial on a speaker. The indicator’s numeric increments make it easy to set the valve to the same flow rate with each use. These valves adjust the volume of air exiting an air cylinder (meter out) to control the speed of air-powered equipment. They control flow in one direction as air moves from the inlet to the outlet. Air flows freely in the opposite direction. The elbow shape allows you to mount them directly to cylinder ports, eliminating additional tubing between the cylinder and valve for better control and consistency than inline valves. Insert plastic or soft metal tubing into the push-to-connect outlet ports.

Flow coefficient (Cv) is a measurement that indicates how much airflow can pass through a valve. When selecting between valves with the same port size, choose the valve with the higher flow coefficient to ensure it provides enough airflow to operate your system.

Flow Rate @ 73 psi | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Inlet Pipe Size | For Outlet Tube OD, mm | Flow Coefficient (Cv) | Min. | Max. | Max. Pressure, psi | Temp. Range, °F | Flow Adjustment Mechanism | Flow Control Type | ISO Designation | Each | |

PBT Plastic Body | |||||||||||

| 1/8 | 6 | 0.17 | 0 scfm | 5.2 scfm | 145 | 25° to 140° | Dial | Exiting Cylinder | Meter Out | 0000000 | 000000 |

| 1/4 | 8 | 0.17 | 0 scfm | 5.2 scfm | 145 | 25° to 140° | Dial | Exiting Cylinder | Meter Out | 0000000 | 00000 |

Precision-Adjust Air Flow Control Valves

Push-to-Connect

Female Outlet

Female Inlet ×

Threaded Male Outlet

A fine-adjustment dial allows tighter control of airflow and cylinder speed than with other flow control valves. These valves control the speed of air-powered equipment by adjusting the volume of airflow. They control flow in one direction as air moves from the inlet to the outlet. Air flows freely in the opposite direction. The elbow shape allows you to mount them directly to cylinder ports, eliminating additional tubing or piping between the cylinder and valve for better control and consistency than inline valves.

Meter out valves control flow as it exits the cylinder. Meter in valves control flow as it enters the cylinder.

Valves with push-to-connect ports are for use with plastic or soft metal tubing. Insert tubing into the port

Flow coefficient (Cv) is a measurement that indicates how much airflow can pass through a valve. When selecting between valves with the same port size, choose the valve with the higher flow coefficient to ensure it provides enough airflow to operate your system.

Inlet | Outlet | Flow Rate @ 73 psi | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Flow Control Type | ISO Designation | Flow Adjustment Mechanism | Inlet Pipe Size | For Outlet Tube OD, mm | Flow Coefficient (Cv) | Min. | Max. | Max. Pressure, psi | Temp. Range, °F | Each | |

PBT Plastic Body | |||||||||||

| Exiting Cylinder | Meter Out | Dial | 1/8 | 4 | 0.15 | 0 scfm | 7.2 scfm | 145 | 32° to 140° | 0000000 | 000000 |

| Exiting Cylinder | Meter Out | Dial | 1/8 | 6 | 0.19 | 0 scfm | 9.2 scfm | 145 | 32° to 140° | 0000000 | 00000 |

| Exiting Cylinder | Meter Out | Dial | 1/8 | 8 | 0.19 | 0 scfm | 9.2 scfm | 145 | 32° to 140° | 0000000 | 00000 |

| Exiting Cylinder | Meter Out | Dial | 1/4 | 4 | 0.22 | 0 scfm | 11.2 scfm | 145 | 32° to 140° | 0000000 | 00000 |

| Exiting Cylinder | Meter Out | Dial | 1/4 | 6 | 0.33 | 0 scfm | 15.6 scfm | 145 | 32° to 140° | 0000000 | 00000 |

| Exiting Cylinder | Meter Out | Dial | 1/4 | 8 | 0.39 | 0 scfm | 18.4 scfm | 145 | 32° to 140° | 0000000 | 00000 |

| Exiting Cylinder | Meter Out | Dial | 1/4 | 10 | 0.39 | 0 scfm | 18.4 scfm | 145 | 32° to 140° | 0000000 | 00000 |

Inlet | Outlet | Flow Rate @ 73 psi | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Flow Control Type | ISO Designation | Flow Adjustment Mechanism | For Inlet Tube OD, mm | Outlet Pipe Size | Flow Coefficient (Cv) | Min. | Max. | Max. Pressure, psi | Temp. Range, °F | Each | |

PBT Plastic Body | |||||||||||

| Entering Cylinder | Meter In | Dial | 4 | 1/4 | 0.22 | 0 scfm | 11.2 scfm | 145 | 32° to 140° | 0000000 | 000000 |

| Entering Cylinder | Meter In | Dial | 4 | 1/8 | 0.15 | 0 scfm | 7.2 scfm | 145 | 32° to 140° | 0000000 | 00000 |

| Entering Cylinder | Meter In | Dial | 6 | 1/4 | 0.33 | 0 scfm | 15.6 scfm | 145 | 32° to 140° | 0000000 | 00000 |

| Entering Cylinder | Meter In | Dial | 6 | 1/8 | 0.19 | 0 scfm | 9.2 scfm | 145 | 32° to 140° | 0000000 | 00000 |

| Entering Cylinder | Meter In | Dial | 8 | 1/4 | 0.39 | 0 scfm | 18.4 scfm | 145 | 32° to 140° | 0000000 | 00000 |

| Entering Cylinder | Meter In | Dial | 8 | 1/8 | 0.19 | 0 scfm | 9.2 scfm | 145 | 32° to 140° | 0000000 | 00000 |

| Entering Cylinder | Meter In | Dial | 10 | 1/4 | 0.39 | 0 scfm | 18.4 scfm | 145 | 32° to 140° | 0000000 | 00000 |

Elbow Corrosion-Resistant Air Flow Control Valves

Push-to-Connect

Female Outlet

Mount these valves directly to cylinder ports, eliminating additional tubing or piping between the cylinder and valve for better control than inline valves. Made of stainless steel and plastic parts, they’re more corrosion resistant than valves made of brass, aluminum, or zinc. Use them to control the speed of air-powered equipment by adjusting the volume of airflow. They control flow in one direction as air moves from the inlet to the outlet. Air flows freely in the opposite direction.

Meter out valves control flow as it exits the cylinder. Valves with push-to-connect ports are for use with plastic or soft metal tubing. Insert tubing into the port.

Valves with a pressure-release button allow you to exhaust any trapped air pressure from the system after shut down.

Flow coefficient (Cv) is a measurement that indicates how much airflow can pass through a valve. When selecting between valves with the same port size, choose the valve with the higher flow coefficient to ensure it provides enough airflow to operate your system.

Flow Rate @ 73 psi | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Inlet Pipe Size | For Outlet Tube OD, mm | Flow Coefficient (Cv) | Min. | Max. | Max. Pressure, psi | Temp. Range, °F | Flow Adjustment Mechanism | Flow Control Type | ISO Designation | Each | |

PBT Plastic Body with Pressure-Release Button | |||||||||||

| 1/8 | 6 | 0.07 | 0 scfm | 2.6 scfm | 145 | 25° to 140° | Dial | Exiting Cylinder | Meter Out | 0000000 | 000000 |

| 1/8 | 8 | 0.07 | 0 scfm | 2.6 scfm | 145 | 25° to 140° | Dial | Exiting Cylinder | Meter Out | 0000000 | 00000 |

| 1/4 | 8 | 0.07 | 0 scfm | 2.6 scfm | 145 | 25° to 140° | Dial | Exiting Cylinder | Meter Out | 0000000 | 00000 |

High-Pressure Air Flow Control Valves

These valves handle pressure up to 265 psi. They adjust the volume of air exiting an air cylinder (meter out) to control the speed of air-powered equipment. Use them to control flow in one direction as air moves from the inlet to the outlet. Air flows freely in the opposite direction. The inlet has a universal thread for connecting to NPT, NPTF (Dryseal), BSPP, and BSPT threads. Insert plastic or soft metal tubing into the push-to-connect outlet ports. The elbow shape allows you to mount them directly to cylinder ports, eliminating additional piping between the cylinder and valve for better control and consistency than inline valves.

Flow coefficient (Cv) is a measurement that indicates how much airflow can pass through a valve. When selecting between valves with the same port size, choose the valve with the higher flow coefficient to ensure it provides enough airflow to operate your system.

| Inlet Pipe Size | For Outlet Tube OD | Flow Coefficient (Cv) | Maximum Flow Rate @ 100 psi | Max. Pressure, psi | Temp. Range, °F | Flow Adjustment Mechanism | Flow Control Type | ISO Designation | Each | |

BSPP, BSPT, NPT, NPTF Male Inlet × Push-to-Connect Female Outlet | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Brass Body | ||||||||||

| 1/8 | 1/8" | 0.09 | 5 scfm | 265 | -20° to 175° | Dial | Exiting Cylinder | Meter Out | 0000000 | 000000 |

| 1/8 | 5/32" | 0.14 | 7.8 scfm | 265 | -20° to 175° | Slotted Screw | Exiting Cylinder | Meter Out | 0000000 | 00000 |

| 1/8 | 1/4" | 0.22 | 12.3 scfm | 265 | -20° to 175° | Dial | Exiting Cylinder | Meter Out | 0000000 | 00000 |

| 1/8 | 1/4" | 0.22 | 12.3 scfm | 265 | -20° to 175° | Slotted Screw | Exiting Cylinder | Meter Out | 0000000 | 00000 |

| 1/4 | 1/4" | 0.27 | 15.1 scfm | 265 | -20° to 175° | Dial | Exiting Cylinder | Meter Out | 0000000 | 00000 |

| 1/4 | 1/4" | 0.27 | 15.1 scfm | 265 | -20° to 175° | Slotted Screw | Exiting Cylinder | Meter Out | 0000000 | 00000 |

| 1/4 | 3/8" | 0.41 | 23 scfm | 265 | -20° to 175° | Dial | Exiting Cylinder | Meter Out | 0000000 | 00000 |

| 1/4 | 3/8" | 0.41 | 23 scfm | 265 | -20° to 175° | Slotted Screw | Exiting Cylinder | Meter Out | 0000000 | 00000 |

| 3/8 | 3/8" | 0.42 | 23.5 scfm | 265 | -20° to 175° | Dial | Exiting Cylinder | Meter Out | 0000000 | 00000 |

| 3/8 | 3/8" | 0.42 | 23.5 scfm | 265 | -20° to 175° | Slotted Screw | Exiting Cylinder | Meter Out | 0000000 | 00000 |

Dual-Control Two-Direction Air Flow Control Valves

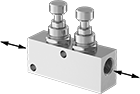

Two knobs independently control airflow in each direction. These valves control flow in two directions as air moves from the inlet to the outlet and from the outlet to the inlet. They’re often used to control both the extension speed as flow enters a cylinder (meter in), and the retraction speed as flow exits a cylinder (meter out). For the best control, mount them as close to the cylinder as possible to minimize the length of piping between the cylinder and the valve.

Flow coefficient (Cv) is a measurement that indicates how much airflow can pass through a valve.

| Inlet Pipe Size | Outlet Pipe Size | Flow Coefficient (Cv) | Maximum Flow Rate @ 100 psi | Max. Pressure, psi | Temp. Range, °F | Flow Adjustment Mechanism | Flow Control Type (ISO Designation) | Each | |

BSPP Female Inlet × BSPP Female Outlet | |||||||||

|---|---|---|---|---|---|---|---|---|---|

Aluminum Body | |||||||||

| 1/8 | 1/8 | 0.18 | 6.8 scfm | 145 | 0° to 140° | Dial | Exiting Cylinder (Meter Out), Entering Cylinder (Meter In) | 0000000 | 0000000 |

Single-Control Two-Direction Air Flow Control Valves

A single dial adjusts the speed of airflow equally in both directions. These valves control flow in two directions as air moves from the inlet to the outlet and from the outlet to the inlet. They’re often used to control the extension speed as flow enters a cylinder (meter in), and the retraction speed as flow exits a cylinder (meter out) at the same time. For the best control, mount them as close to the cylinder as possible to minimize the length of tubing between the cylinder and the valve.

Flow coefficient (Cv) is a measurement that indicates how much airflow can pass through a valve.

| Inlet Pipe Size | Outlet Pipe Size | Flow Coefficient (Cv) | Maximum Flow Rate @ 100 psi | Max. Pressure, psi | Temp. Range, °F | Flow Adjustment Mechanism | Flow Control Type (ISO Designation) | Each | |

Aluminum Body | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1/8 | 1/8 | 0.19 | 7.2 scfm | 145 | -4° to 140° | Dial | Exiting Cylinder (Meter Out), Entering Cylinder (Meter In) | 0000000 | 000000 |

| 1/4 | 1/4 | 0.35 | 13 scfm | 145 | -4° to 140° | Dial | Exiting Cylinder (Meter Out), Entering Cylinder (Meter In) | 0000000 | 000000 |

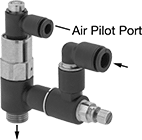

Air-Operated Air Flow Control Valves with Safety Shut-Off

Protect air-powered equipment in emergency shut-off situations—when system pressure drops, the air pilot signal stops and these valves automatically close to stop cylinder motion, even at a mid-stroke. They control the speed of air-powered equipment by adjusting the volume of airflow. A pressure-release button allows you to exhaust any trapped air pressure from the system after shut down. Install them in pairs on cylinder exhaust ports, and use tee connectors (not included) to direct exhaust air from the cylinder to the air pilot of the opposite valve, and to connect valves to a directional control valve. The elbow shape allows you to mount them directly to cylinder ports, eliminating additional tubing or piping between the cylinder and valve for better control and consistency than inline valves.

One direction valves control flow as air exits the cylinder (meter out) and moves from the inlet to the outlet.

Valves with push-to-connect ports are for use with plastic or soft metal tubing. Insert tubing into the port.

Flow coefficient (Cv) is a measurement that indicates how much airflow can pass through a valve.

| For Inlet Tube OD, mm | Outlet Pipe Size | For Air Pilot Tube OD, mm | Flow Coefficient (Cv) | Maximum Flow Rate @ 87 psi | Max. Pressure, psi | Temp. Range, °F | Flow Adjustment Mechanism | Flow Control Type (ISO Designation) | Features | Each | |

Nylon Plastic Body—One Direction | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 6 | 1/4 | 4 | Not Rated | 16.77 scfm | 145 | 25° to 140° | Dial | Exiting Cylinder (Meter Out) | Pressure-Release Button | 00000000 | 0000000 |

| 8 | 1/8 | 4 | Not Rated | 8.48 scfm | 145 | 25° to 140° | Dial | Exiting Cylinder (Meter Out) | Pressure-Release Button | 00000000 | 000000 |

| 8 | 3/8 | 4 | Not Rated | 30.9 scfm | 145 | 25° to 140° | Dial | Exiting Cylinder (Meter Out) | Pressure-Release Button | 00000000 | 000000 |

| 10 | 3/8 | 4 | Not Rated | 33.2 scfm | 145 | 25° to 140° | Dial | Exiting Cylinder (Meter Out) | Pressure-Release Button | 00000000 | 000000 |

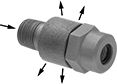

Air-Exhaust Flow Control Valves

Install these valves in the exhaust ports of air directional control valves to control exhaust air speed without needing access to your cylinder. They control flow in one direction as air moves from the inlet to the exhaust port (meter out). Air flows freely in the opposite direction. Valves exhaust to the atmosphere and include a muffler to reduce the exhaust noise.

Flow coefficient (Cv) is a measurement that indicates how much airflow can pass through a valve. When selecting between valves with the same port size, choose the valve with the higher flow coefficient to ensure it provides enough airflow to operate your system.

Overall | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| No. of Flow Ports | Inlet Size | Max. Flow Rate, scfm @ 100 psi | Flow Coefficient (Cv) | Max. Pressure, psi | Body Material | Hex Size | Dia. | Lg. | Each | |

Threaded Male Inlet | ||||||||||

Dial Flow Adjustment Mechanism | ||||||||||

| 2 | 1/8 BSPP | 35 | 1.016 | 145 | Aluminum | __ | 16mm | 46mm | 0000000 | 000000 |

| 2 | 1/4 BSPP | 52.5 | 1.524 | 145 | Aluminum | __ | 19.5mm | 63.3mm | 0000000 | 00000 |

| 2 | 3/8 BSPP | 59.5 | 1.728 | 145 | Aluminum | __ | 25mm | 95.3mm | 0000000 | 00000 |

| 2 | 1/2 BSPP | 141.26 | 2.982 | 145 | Aluminum | __ | 28mm | 130mm | 00000000 | 00000 |

| 2 | 3/4 BSPP | 268.39 | 5.965 | 145 | Aluminum | __ | 38mm | 157mm | 00000000 | 00000 |

Slotted Screw Flow Adjustment Mechanism | ||||||||||

| 2 | 1/8 BSPP | 19.21 | 0.52 | 145 | Aluminum | 14mm | 15mm | 27mm | 00000000 | 00000 |

| 2 | 1/4 BSPP | 37 | 1 | 145 | Aluminum | 17mm | 18.2mm | 32.1mm | 00000000 | 00000 |

| 2 | 3/8 BSPP | 74 | 2 | 145 | Aluminum | 22mm | 25mm | 41.1mm | 00000000 | 00000 |

| 2 | 1/2 BSPP | 133.2 | 3.6 | 145 | Aluminum | 24mm | 27mm | 44.6mm | 00000000 | 00000 |

Thumb Screw Flow Adjustment Mechanism | ||||||||||

| 2 | 1/8 BSPT | 10.59 | 0.201 | 145 | Brass | 10mm | 14mm | 35.8mm | 00000000 | 00000 |

| 2 | 1/4 BSPT | 17.66 | 0.313 | 145 | Brass | 14mm | 18mm | 37mm | 00000000 | 00000 |