About Pressure Gauges

More

About Pressure Transmitters

More

About Pipe Size

More

Pressure Gauges

These are the most commonly used pressure gauges. Use them with pumps, filters, regulators, and in process lines to measure and display pressure.

Gauges with 304 stainless steel case or ABS plastic case have better corrosion resistance than gauges with brass or steel case.

- For Use With: Air, Water, Hydraulic Fluid, Carbon Dioxide, and Natural Gas

- Accuracy: ±2% Mid Scale (Grade B)

- Mount with the dial face upright

Available Pressure Ranges | |||||

|---|---|---|---|---|---|

Pressure Range | Graduation Marks | Numeric Increments | |||

| psi | kPa | psi | kPa | psi | kPa |

| 0 to 30 | 0 to 200 | 1 | 5 | 5 | 50 |

| 0 to 60 | 0 to 400 | 2 | 10 | 10 | 100 |

| 0 to 100 | 0 to 700 | 2 | 20 | 20 | 100 |

| 0 to 160 | 0 to 1,100 | 5 | 20 | 20 | 200 |

| 0 to 200 | 0 to 1,400 | 5 | 50 | 40 | 200 |

| 0 to 300 | 0 to 2,000 | 10 | 50 | 50 | 500 |

| 0 to 600 | 0 to 4,000 | 20 | 100 | 100 | 1,000 |

| 0 to 1,000 | 0 to 7,000 | 20 | 200 | 200 | 1,000 |

Bottom Connection | Center Back Connection | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Dial Diameter | Pipe Size | Environment Temp. Range, °F | Process Temp. Range, °F | Case Color | Mounting Orientation | Each | Each | ||

BSPT Male | |||||||||

| 1 5/8" | 1/8 | -40° to 120° | -40° to 120° | Black | Upright | 0000000 | 000000 | 0000000 | 000000 |

| 2" | 1/4 | -40° to 120° | -40° to 120° | Black | Upright | 0000000 | 00000 | 0000000 | 00000 |

| 2 1/2" | 1/4 | -40° to 120° | -40° to 120° | Black | Upright | 0000000 | 00000 | 0000000 | 00000 |

Miniature Pressure Gauges

The small dial on these gauges allows for installation in tight spaces. Use them with pumps, filters, regulators, and in process lines to measure and display pressure.

Gauges with ABS plastic case are more corrosion resistant than brass-case gauges.

- For Use With: Air, Water, Hydraulic Fluid, Ethyl Alcohol, Nitrogen, and Natural Gas

- Accuracy: ±4% Full Scale (Not Graded)

Available Pressure Ranges | ||

|---|---|---|

| Pressure Range, psi | Graduation Marks, psi | Numeric Increments, psi |

| 0 to 60 | 2 | 10 |

| 0 to 100 | 2 | 20 |

| 0 to 160 | 4 | 40 |

Center Back Connection | |||||||

|---|---|---|---|---|---|---|---|

| Dial Diameter | Pipe Size | Environment Temp. Range, °F | Process Temp. Range, °F | Case Color | Mounting Orientation | Each | |

BSPT Male | |||||||

| 1" | 1/8 | 32° to 140° | 0° to 140° | Black | Any | 000000000 | 000000 |

Vibration-Resistant Pressure Gauges

A liquid-filled dial reduces needle flutter for precise readings in high-vibration applications. Gauges are commonly used with pumps, filters, regulators, and in process lines to measure and display pressure. Mount them with the dial face upright.

Gauges with 304 stainless steel case and ABS plastic case have better corrosion resistance than gauges with brass case.

- For Use With: Air, Water, Hydraulic Fluid, Carbon Dioxide, and Natural Gas

- Accuracy: ±1.5% Full Scale (Not Graded)

Available Pressure Ranges | |||||

|---|---|---|---|---|---|

Pressure Range | Graduation Marks | Numeric Increments | |||

| psi | bar | psi | bar | psi | bar |

BSPP Male | |||||

| 0 to 14.4 | 0 to 1 | 0.4 | 0.02 | 4 | 0.2 |

| 0 to 22.8 | 0 to 1.6 | 0.6 | 0.04 | 6 | 0.4 |

| 0 to 36 | 0 to 2.5 | 1 | 0.05 | 10 | 0.5 |

| 0 to 57.6 | 0 to 4 | 1.6 | 0.1 | 16 | 1 |

| 0 to 86 | 0 to 6 | 2 | 0.1 | 20 | 1 |

| 0 to 144 | 0 to 10 | 4 | 0.2 | 40 | 2 |

| 0 to 228 | 0 to 16 | 6 | 0.4 | 60 | 4 |

| 0 to 360 | 0 to 25 | 10 | 0.5 | 100 | 5 |

| 0 to 576 | 0 to 40 | 16 | 1 | 160 | 10 |

| 0 to 860 | 0 to 60 | 20 | 1 | 200 | 10 |

| 0 to 1,440 | 0 to 100 | 40 | 2 | 400 | 20 |

| 0 to 2,280 | 0 to 160 | 60 | 4 | 600 | 40 |

| 0 to 3,600 | 0 to 250 | 100 | 5 | 1,000 | 50 |

| 0 to 5,800 | 0 to 400 | 160 | 10 | 1,600 | 100 |

| 0 to 8,600 | 0 to 600 | 200 | 10 | 2,000 | 100 |

Absolute Pressure Gauges

Unlike other gauges that measure the difference between your system and the atmosphere, these give measurements relative to zero pressure. They’re often used in laboratory applications, and they are barometrically independent.

Stainless steel gauges have excellent corrosion resistance, so they can be used with more corrosive liquids and gasses than gauges with a brass connection and aluminum case.

- For Use With: Air, Carbon Dioxide, Diesel Fuel, Ethyl Alcohol, Gasoline, Hydraulic Fluid, Natural Gas, Water

- Accuracy: ±1% Full Scale (Not Graded)

Available Pressure Ranges | ||

|---|---|---|

| Pressure Range, mbar | Numeric Increments, mbar | Graduation Marks, mbar |

| 0 to 25 | 5 | 0.5 |

| 0 to 60 | 10 | 1 |

| 0 to 160 | 50 | 5 |

| 0 to 600 | 100 | 10 |

| 0 to 1,000 | 200 | 20 |

Bottom Connection | ||||||

|---|---|---|---|---|---|---|

| Dial Diameter | Pipe Size | Environment Temp. Range, °F | Process Temp. Range, °F | Lens Material | Each | |

BSPP Male | ||||||

| 4" | 1/2 | 5° to 120° | 0° to 200° | Glass | 000000 | 000000000 |

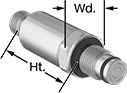

Flush-Mount Pressure Transmitters

- For Use With: Air, Argon, Diesel Fuel, Hydraulic Fluid, Nitrogen, Water

- Accuracy: ±0.05%

- Pipe Connection: BSPP Male

- Housing Material: 316 Stainless Steel

- Connection Material: 316 Stainless Steel

- Diaphragm Material: Fluoroelastomer Rubber

- Temperature Range: -10° to 190° F

The diaphragm on these transmitters mounts flush with your system’s connection, leaving no room for thick liquids to clog or harden. They’re often used to monitor pressure in wastewater, paint, and adhesive-dispensing applications. Also known as transducers, they convert pressure to an electrical signal that can be interpreted by receiving devices, such as remote displays, programmable logic controllers, and motor speed controls. For your receiving device to interpret the signal from the transmitter, you will need to calibrate it for the transmitter's pressure range and output signal. As pressure increases, the output signal from the transmitter will increase. Transmitters will only provide accurate readings within the rated pressure range.

All are rated IP67 and IP69K, so they'll withstand temporary submersion as well as high-pressure, high-temperature washdowns. CE marked, they meet European safety standards.

Connect using two wires. The same wire is used to send a signal to the receiver and to power the transmitter. Current doesn’t lose signal over long distances and isn’t affected by electrical interference from other devices.

| Pressure Range, psi | Maximum Continuous Pressure, psi | Maximum Short-Term Pressure, psi | Input Voltage | Pipe Size | Ht. | Wd. | Environmental Rating | Each | |

4-20mA Current Output—2-Pole Micro M12 Connection | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 0-870 | 2,175 | 2,175 | 8.5-36V DC | 1/4 | 1 1/2" | 3/4" | IP67, IP69K | 0000000 | 0000000 |

| 0-1,450 | 3,625 | 3,625 | 8.5-36V DC | 1/4 | 1 1/2" | 3/4" | IP67, IP69K | 0000000 | 000000 |

| 0-2,320 | 5,800 | 5,800 | 8.5-36V DC | 1/4 | 1 1/2" | 3/4" | IP67, IP69K | 0000000 | 000000 |

| 0-3,625 | 9,060 | 9,060 | 8.5-36V DC | 1/4 | 1 1/2" | 3/4" | IP67, IP69K | 0000000 | 000000 |

| 0-5,800 | 11,580 | 11,580 | 8.5-36V DC | 1/4 | 1 1/2" | 3/4" | IP67, IP69K | 0000000 | 000000 |

Pressure and Vacuum Transmitters with Digital Display

- For Use With: Air, Argon, Diesel Fuel, Hydraulic Fluid, Nitrogen, Water

- Accuracy: ±1%

- Pipe Connection Type: Threaded

- Housing Material: Glass-Reinforced Polyester

- Connection Material: 316L Stainless Steel

- Temperature Range: -10° to 175°F

Monitor and control vacuum pumps, air compressors, and hydraulics while viewing readings and warnings on the display. These transmitters, also called transducers, have two outputs, so you can program them to work as a transmitter, a switch, or both. When they reach their setpoint, they send electrical signals to your programmable logic controller (PLC) to trigger actions in your system. Adjust their reset point anywhere within the setpoint range. To change settings and receive error messages remotely from your PLC or computer, program one of the outputs to use IO Link. You need an IO-Link controller (not included) to connect to your interface.

Buttons on the display let you change your setpoint, measuring range, and other settings. To quickly tell the status of your process, you can program the color of the display to red and green. LEDs on the corners also notify you of your output’s switching status. Rotate the head to view the display from the best angle.

You must calibrate your PLC in order for it to interpret signals from these transmitters. As pressure increases, the output signal from the transmitter will increase. These transmitters only give accurate readings within the rated pressure or vacuum range.

All have an M12 plug to connect to M12 Connectors. When using both switching outputs and an IO-Link controller, they require four wires to connect. For their 4-20mA analog output, they need two wires to connect. View switch wiring diagrams by selecting a part number and clicking Product Detail.

To withstand wet environments, these transmitters have a 316L stainless steel connection and are IP rated. Their IP ratings also mean they’re dust tight and stand up to spraying water and brief submersion. UL and C-UL listed as well as CE marked, they meet strict American, Canadian, and European safety standards.

Setpoint Range | Configurable Analog Transmitter/Digital Switch Output | Configurable Digital Switch Output | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pressure Range, psi | Vacuum Range, in. of Hg | Max. Continuous and Short-Term Pressure, psi | Pressure, psi | Vacuum, in. of Hg | Input Voltage | Pipe Size | Ht. | Wd. | No. of | Current | Signal Type | No. of | Signal Type | Scale | Each | |

BSPP Female | ||||||||||||||||

| 0-7.3 | 14.8-0 | 145 | 0-7.3 | 14.8-0 | 18-30V DC | 1/4 | 3 9/16" | 1 3/8" | 1 | 4-20mA | NPN, PNP | 1 | NPN, PNP | in. of H2O, kPa, mbar, psi | 0000000 | 0000000 |

| 0-14.5 | 1.4-0 | 145 | 0-14.5 | 1.4-0 | 18-30V DC | 1/4 | 3 9/16" | 1 3/8" | 1 | 4-20mA | NPN, PNP | 1 | NPN, PNP | in. of H2O, kPa, mbar, psi | 0000000 | 000000 |

| 0-14.5 | 29.5-0 | 145 | 0-14.5 | 29.5-0 | 18-30V DC | 1/4 | 3 9/16" | 1 3/8" | 1 | 4-20mA | NPN, PNP | 1 | NPN, PNP | in. of H2O, in. of Hg, kPa, mbar, psi | 0000000 | 000000 |

| 0-87 | 29.5-0 | 600 | 0-87 | 29.5-0 | 18-30V DC | 1/4 | 3 9/16" | 1 3/8" | 1 | 4-20mA | NPN, PNP | 1 | NPN, PNP | bar, MPa, psi | 0000000 | 000000 |

| 0-145 | 29.7-0 | 1,085 | 0-145 | 29.7-0 | 18-30V DC | 1/4 | 3 9/16" | 1 3/8" | 1 | 4-20mA | NPN, PNP | 1 | NPN, PNP | bar, MPa, psi | 0000000 | 000000 |

| 0-360 | 29.5-0 | 2,175 | 0-360 | 29.5-0 | 18-30V DC | 1/4 | 3 9/16" | 1 3/8" | 1 | 4-20mA | NPN, PNP | 1 | NPN, PNP | bar, MPa, psi | 0000000 | 000000 |

BSPP Male | ||||||||||||||||

| 0-7.3 | 14.8-0 | 145 | 0-7.3 | 14.8-0 | 18-30V DC | 1/4 | 3 11/16" | 1 3/8" | 1 | 4-20mA | NPN, PNP | 1 | NPN, PNP | bar, MPa, psi | 0000000 | 000000 |

| 0-14.5 | 1.4-0 | 145 | 0-14.5 | 1.4-0 | 18-30V DC | 1/4 | 3 11/16" | 1 3/8" | 1 | 4-20mA | NPN, PNP | 1 | NPN, PNP | bar, MPa, psi | 0000000 | 000000 |

| 0-14.5 | 29.5-0 | 145 | 0-14.5 | 29.5-0 | 18-30V DC | 1/4 | 3 11/16" | 1 3/8" | 1 | 4-20mA | NPN, PNP | 1 | NPN, PNP | in. of H2O, in. of Hg, kPa, mbar, psi | 0000000 | 000000 |

| 0-87 | 29.5-0 | 600 | 0-87 | 29.5-0 | 18-30V DC | 1/4 | 3 11/16" | 1 3/8" | 1 | 4-20mA | NPN, PNP | 1 | NPN, PNP | bar, MPa, psi | 0000000 | 000000 |

| 0-145 | 29.7-0 | 1,085 | 0-145 | 29.7-0 | 18-30V DC | 1/4 | 3 11/16" | 1 3/8" | 1 | 4-20mA | NPN, PNP | 1 | NPN, PNP | bar, MPa, psi | 0000000 | 000000 |

| 0-360 | 29.5-0 | 145 | 0-360 | 29.5-0 | 18-30V DC | 1/4 | 3 11/16" | 1 3/8" | 1 | 4-20mA | NPN, PNP | 1 | NPN, PNP | bar, MPa, psi | 0000000 | 000000 |