Filter by

For Finish

Grit Rating

For Polishing Step

Abrasive Material

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Sold As

Buffing and Polishing Compounds

|

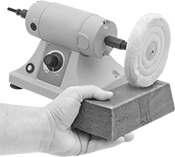

Remove scratches, oxidation, and other surface imperfections from your workpiece. Apply a layer of compound by holding these bars against a revolving buffing wheel or polishing bob. Microns are approximate.

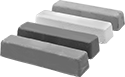

Most buffing processes have two steps, cutting and coloring.

1. Cutting removes scratches and imperfections.

2. Coloring produces an even finish.

Cutting/coloring compounds perform both steps at once.

4 oz. | 6 oz. | 1 lb. | 3 lb. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Abrasive Material | Abrasive Grain Size, μm | For Finish | Color | Each | Each | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Steel and Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Cutting | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Aluminum Oxide | 40 | Extra Smooth | Gray | ——— | 0 | 0000000 | 00000 | 0000000 | 00000 | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Coloring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Chrome Oxide | 1 | Polished | Green | ——— | 0 | 00000000 | 0000 | 00000000 | 00000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Cutting/Coloring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Calcined Alumina | 5 | Polished | Yellow | ——— | 0 | ——— | 0 | 0000000 | 0000 | 000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Steel, Stainless Steel, Aluminum, Brass, Bronze, and Copper | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Coloring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Calcined Alumina | 2 | Polished | White | ——— | 0 | 0000000 | 0000 | ——— | 0 | 000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Aluminum, Brass, Bronze, and Copper | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Cutting | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Silica | 45 | Extra Smooth | Brown Tripoli | ——— | 0 | ——— | 0 | ——— | 0 | 000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Cutting/Coloring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Silica | 35 | Extra Smooth | Brown Tripoli | ——— | 0 | 0000000 | 0000 | 0000000 | 0000 | 000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Brass, Bronze, and Copper | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Coloring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Iron Oxide | 0.5 | Polished | Red Rouge | ——— | 0 | 0000000 | 0000 | ——— | 0 | 000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Fiberglass | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Coloring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Calcined Alumina | 1 | Polished | Blue | ——— | 0 | 0000000 | 0000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Calcined Alumina | 1 | Polished | White | ——— | 0 | ——— | 0 | 0000000 | 0000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Plastic and Rubber | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Cutting | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Silica | 45 | Extra Smooth | Beige | ——— | 0 | 0000000 | 0000 | 0000000 | 0000 | 000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Coloring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Quartz | 15 | Polished | Tan | ——— | 0 | ——— | 0 | 00000000 | 0000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Silica | 15 | Polished | Brown | 00000000 | 00000 | ——— | 0 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aggressive Buffing and Polishing Compounds

|

Remove more material than traditional buffing compounds. These consist of abrasive grains embedded in glue to adhere to your buffing wheel. They remove scratches and surface imperfections and leave a dull satin finish. Also known as greaseless compounds. Apply by holding one of these bars against a revolving buffing wheel. Grit is approximate.

Cutting, the first step in the buffing process, removes scratches and surface imperfections.

3 lb. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Abrasive Material | Abrasive Grain Size, μm | Grit (For Finish) | Color | Dia. | Lg. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Steel, Stainless Steel, Aluminum, Brass, Bronze, and Copper | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Cutting | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Aluminum Oxide | 38 | 400 (Extra Smooth) | Black | 2 1/2" | 10 1/2" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Aluminum Oxide | 40 | 280 (Extra Smooth) | Black | 2 1/2" | 10 1/2" | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Aluminum Oxide | 60 | 240 (Extra Smooth) | Red | 2 1/2" | 10 1/2" | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Aluminum Oxide | 80 | 180 (Smooth) | Red | 2 1/2" | 10 1/2" | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Aluminum Oxide | 100 | 150 (Smooth) | Red | 2 1/2" | 10 1/2" | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Aluminum Oxide | 120 | 120 (Smooth) | Red | 2 1/2" | 10 1/2" | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Aluminum Oxide | 173 | 80 (Rough) | Red | 2 1/2" | 10 1/2" | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Buffing and Polishing Compound Assortments

|

Apply a layer of compound by holding one of these bars against a revolving buffing wheel.

Most buffing processes have two steps, cutting and coloring.

1. Cutting removes scratches and surface imperfections.

2. Coloring produces and even finish.

Cutting/Coloring perform both steps at once.

No. of Pieces | Includes | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Cutting, Coloring, and Cutting/Coloring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | One 4 oz. Smooth-Finish Gray Cutting Compound One 4 oz. Extra-Smooth-Finish Brown Cutting/Coloring Compound One 4 oz. Polished-Finish White Rouge Coloring Compound One 4 oz. Polished-Finish Red Rouge Coloring Compound | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | One 1 lb. Extra-Smooth-Finish Brown Cutting/Coloring Compound One 1 lb. Extra-Smooth-Finish Tan Cutting Compound One 1 lb. Polished-Finish White Rouge Coloring Compound One 1 lb. Polished-Finish Yellow Cutting/Coloring Compound One 1 lb. Polished-Finish White Coloring Compound One 1 lb. Polished-Finish Red Coloring Compound | 000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||