How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

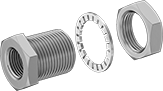

Plastic Pipe Fittings for Oil

Made of corrosion-resistant plastic, these fittings won’t deteriorate when used in oil applications. They also have high strength and impact resistance. Apply a non-hardening, plastic-compatible sealant to the male threads to prevent leaks. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

Through-wall fittings are also known as bulkhead couplings and panel-mount couplings; they mount through a wall, tank, or panel to create an inlet or outlet for faucets, pipes, and spigots. They are for use on flat and curved surfaces.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

- For Use With: Oil

- Temperature Range: -20° to 140° F

Connectors | Replacement Gaskets | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | For Hole Dia. | For Max. Wall Thick. | Material | Color | Gasket Material | Max. Pressure | Each | Each | ||

NPT Threads | ||||||||||

| 3/4 | 1 11/16" | 7/16" | Polyethylene Plastic | Black | EPDM Rubber | 120 psi @ 72° F | 000000 | 000000 | 00000000 | 00000 |

| 1 | 2 5/8" | 9/16" | Polyethylene Plastic | Black | EPDM Rubber | 120 psi @ 72° F | 000000 | 00000 | 00000000 | 0000 |

| 1 1/4 | 2 5/8" | 9/16" | Polyethylene Plastic | Black | EPDM Rubber | 120 psi @ 72° F | 000000 | 00000 | 00000000 | 0000 |

| 1 1/2 | 2 5/8" | 9/16" | Polyethylene Plastic | Black | EPDM Rubber | 120 psi @ 72° F | 000000 | 00000 | 00000000 | 0000 |

| 2 | 3 1/4" | 9/16" | Polyethylene Plastic | Black | EPDM Rubber | 120 psi @ 72° F | 000000 | 00000 | 00000000 | 0000 |

Spin-Weld Through-Wall Plastic Tank Fittings

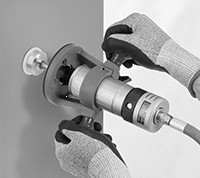

Create a leak-free, durable connection in plastic tanks, walls, or panels without gaskets or sealants. As you spin these fittings with a handheld electric router, they melt into the surface of your tank for a seal without any joints. To hold these fittings in your router, you’ll need the installation tool (sold separately).

For proper installation, you’ll want to use a hole saw to drill a hole that matches the For Hole Diameter listed and check that your router meets the speed and power requirements shown in the table.

- For Use With: Oil, Water

- Temperature Range: 40° to 140° F

For Tank | For Router | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Hose Size | For Hole Dia. | For Min. Wall Thick. | Lg. | Material | Material | Surface | Color | Power | Speed, rpm | Each | |

NPT Female Threaded Pipe × Weld | ||||||||||||

| 1/4 | __ | 0.88" | 3/16" | 15/16" | LDPE Plastic | LDPE Plastic | Flat | White | 1 1/2 | 18,000-25,000 | 0000000 | 00000 |

| 1/2 | __ | 0.88" | 3/16" | 7/8" | LDPE Plastic | LDPE Plastic | Flat | White | 1 1/2 | 18,000-25,000 | 0000000 | 0000 |

| 3/4 | __ | 1.31" | 3/16" | 13/16" | LDPE Plastic | LDPE Plastic | Flat | White | 1 1/2 | 18,000-25,000 | 0000000 | 0000 |

| 1 | __ | 1.5" | 3/16" | 1" | LDPE Plastic | LDPE Plastic | Flat | White | 1 1/2 | 18,000-25,000 | 0000000 | 0000 |

| 1 1/2 | __ | 2" | 3/16" | 1 3/16" | LDPE Plastic | LDPE Plastic | Flat | White | 1 1/2 | 18,000-25,000 | 0000000 | 0000 |

| 2 | __ | 2.5" | 3/16" | 1 3/16" | LDPE Plastic | LDPE Plastic | Flat | White | 1 1/2 | 18,000-25,000 | 0000000 | 0000 |

GHT Male Threaded Hose × Weld | ||||||||||||

| __ | 3/4 | 1" | 3/16" | 7/8" | LDPE Plastic | LDPE Plastic | Flat | White | 1 1/2 | 18,000-25,000 | 0000000 | 0000 |

| For Pipe Size | For Hose Size | Shank Dia. | Overall Lg. | Material | Shank Type | For Tool Type | Each | |

For Pipe Connection | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/4 | __ | 1/4" | 1 5/8" | Aluminum | Straight | Hand Router | 000000 | 0000000 |

| 1/2 | __ | 1/4" | 1 5/8" | Aluminum | Straight | Hand Router | 000000 | 000000 |

| 3/4 | __ | 1/2" | 2" | Aluminum | Straight | Hand Router | 000000 | 000000 |

| 1 | __ | 1/2" | 2 1/4" | Aluminum | Straight | Hand Router | 000000 | 000000 |

| 1 1/2 | __ | 1/2" | 2 1/4" | Aluminum | Straight | Hand Router | 000000 | 000000 |

| 2 | __ | 1/2" | 2 1/4" | Aluminum | Straight | Hand Router | 000000 | 000000 |

For Hose Connection | ||||||||

| __ | 3/4 | 1/4" | 1 3/4" | Aluminum | Straight | Hand Router | 000000 | 000000 |

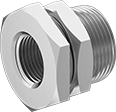

High-Pressure Brass Threaded Pipe Fittings

These fittings have the strength to handle high-pressure applications. They are brass for good corrosion resistance.

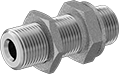

Through-wall fittings are also known as bulkhead couplings and panel-mount couplings; they mount through a wall or panel to create an inlet or outlet.

NPTF (Dryseal) threads are compatible with NPT threads.

- For Use With:

NPT Threads: Air, Water

NPTF, BSPP and Metric Threads: Air, Natural Gas, Oil, Water - Specifications Met: See table

| Pipe Size | Thread Size | For Hole Dia. | For Max. Wall Thick. | Max. Pressure | Specifications Met | Each | |

NPTF Female | |||||||

|---|---|---|---|---|---|---|---|

| 1 | __ | __ | __ | 1,000 psi @ 72° F | __ | 000000000 | 000000 |

BSPP Female | |||||||

| 1/8 | __ | 11/16" | 11/32" | 1,000 psi @ 72° F | SAE J530, SAE J531 | 000000000 | 00000 |

| 1/4 | __ | 13/16" | 37/64" | 1,000 psi @ 72° F | SAE J530, SAE J531 | 000000000 | 00000 |

| 3/8 | __ | 1 1/16" | 35/64" | 1,000 psi @ 72° F | SAE J530, SAE J531 | 000000000 | 00000 |

| 1/2 | __ | 1 1/8" | 25/32" | 1,000 psi @ 72° F | SAE J530, SAE J531 | 000000000 | 00000 |

| 3/4 | __ | 1 3/8" | 7/8" | 1,000 psi @ 72° F | SAE J530, SAE J531 | 000000000 | 00000 |

| 1 | __ | 1 11/16" | 61/64" | 1,000 psi @ 72° F | SAE J530, SAE J531 | 000000000 | 00000 |

Metric Female | |||||||

| __ | M5 × 0.8 mm | 7/16" | 17/64" | 1,000 psi @ 72° F | SAE J530, SAE J531 | 000000000 | 00000 |

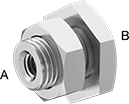

High-Pressure Plated Brass Threaded Pipe Fittings

The plating on these brass fittings creates a shiny finish and provides extra protection in corrosive environments. Fittings have the strength to handle high-pressure applications.

Nickel-plated brass fittings provide better corrosion resistance than unplated brass fittings.

Through-wall fittings are also known as bulkhead couplings and panel-mount couplings; they mount through a wall or panel to create an inlet or outlet.

- For Use With: Air, Natural Gas, Oil, Water

Nickel-Plated Brass | |||||

|---|---|---|---|---|---|

| Pipe Size | Thread Size | For Max. Wall Thick. | Max. Pressure | Each | |

BSPP Female × Metric Male | |||||

| 1/8 | M16 × 1.5 mm | 0.394" | 2,170 psi @ 72° F | 00000000 | 00000 |

| 1/4 | M20 × 1.5 mm | 0.63" | 1,450 psi @ 72° F | 00000000 | 0000 |

| 3/8 | M26 × 1.5 mm | 0.591" | 1,080 psi @ 72° F | 00000000 | 00000 |

| 1/2 | M28 × 1.5 mm | 0.827" | 725 psi @ 72° F | 00000000 | 00000 |

| 3/4 | M33 × 1.5 mm | 0.886" | 1,230 psi @ 72° F | 00000000 | 00000 |

- For Use With: Air, Natural Gas, Oil, Water

Thread Size | Nickel-Plated Brass | ||||

|---|---|---|---|---|---|

| (A) | (B) | For Max. Wall Thick. | Max. Pressure | Each | |

Metric Male × Metric Female | |||||

| M10 × 1 mm | M5 × 0.8 mm | 0.276" | 1,080 psi @ 72° F | 00000000 | 00000 |

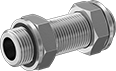

Extreme-Pressure Stainless Steel Threaded Pipe Fittings

With the strength to handle extreme pressures, these fittings can be used to connect equipment in hydraulic fluid lines. 316 stainless steel fittings have excellent corrosion resistance.

Through-wall fittings are also known as bulkhead couplings; they mount through your wall to create an inlet or outlet. When installing, the gasket should be on the inside of the wall. BSPP and metric male threads have either a gasket or a gasket and washer to prevent leaks.

- For Use With: Hydraulic Fluid, Oil, Water

- Specifications Met: ISO 1179, ISO 8434-6

316 Stainless Steel | ||||||

|---|---|---|---|---|---|---|

| Pipe Size | Dash Size | For Max. Wall Thick., mm | Lg., mm | Max. Pressure | Each | |

BSPP Male | ||||||

| 1/8 | 02 | 8 | 43 | 5,000 psi @ 72° F | 00000000 | 000000 |

| 1/4 | 04 | 8 | 46 | 5,000 psi @ 72° F | 00000000 | 00000 |

| 3/8 | 06 | 8 | 55 | 5,000 psi @ 72° F | 00000000 | 00000 |

| 1/2 | 08 | 8 | 59 | 4,500 psi @ 72° F | 00000000 | 00000 |

| 3/4 | 12 | 8 | 64 | 3,600 psi @ 72° F | 00000000 | 000000 |

| 1 | 16 | 8 | 75 | 2,900 psi @ 72° F | 00000000 | 000000 |

- Temperature Range: -22° to 230° F

Compact Extreme-Pressure Steel Threaded Pipe Fittings

These fittings are strong enough to handle extreme pressures, yet small enough to fit into cramped spaces. They are zinc-plated steel, which have better corrosion resistance than plain steel fittings.

Through-wall fittings are also known as bulkhead couplings; they mount through your wall to create an inlet or outlet. When installing, the gasket should be on the inside of the wall. BSPP and metric male threads have either a gasket, or a gasket and washer, to prevent leaks.

Threads with

Gasket and Washer

- For Use With: Air, Hydraulic Fluid, Oil, Water

- Specifications Met: ISO 1179, ISO 8434-6

| Pipe Size | Dash Size | For Hole Dia., mm | For Max. Wall Thick., mm | Max. Pressure | Material | Washer Material | Each | |

BSPP Male | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/4 | 04 | 13 | 11.5 | 6,500 psi @ 72° F | Zinc Plated Steel | Steel | 00000000 | 00000 |

| 3/8 | 06 | 16.5 | 13.9 | 5,500 psi @ 72° F | Zinc Plated Steel | Steel | 00000000 | 00000 |

| 1/2 | 08 | 20.8 | 12.7 | 4,500 psi @ 72° F | Zinc Plated Steel | Steel | 00000000 | 00000 |

| 3/4 | 12 | 26.3 | 11.5 | 3,500 psi @ 72° F | Zinc Plated Steel | Steel | 00000000 | 00000 |

| 1 | 16 | 33.1 | 12.7 | 3,000 psi @ 72° F | Zinc Plated Steel | Steel | 00000000 | 00000 |

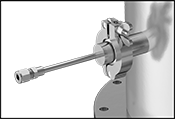

Quick-Clamp Through-Wall Fittings for High-Vacuum Chambers

- For Use With: See table

- Environment Temperature Range: 32° to 300° F

- Process Temperature Range: -325° to 995° F

- Tubing: Use with 304/304L or 316/316L stainless steel

- Specifications Met: ISO 2861

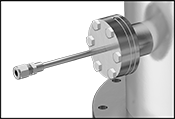

Transfer liquids and gases into high-vacuum chambers with these assembled fittings, also known as feedthroughs. Their quick-clamp (ISO-KF) connections are easier to install and remove than bolt-on flanges. This makes them a good choice for systems that need frequent cleaning, repairs, and setup changes, such as those in teaching and research labs. These fittings meet ISO 2861, which means they’re made to strict dimensional standards that ensure vacuum-tight connections. Made of stainless steel and aluminum, these fittings resist rusting. They are not for use in pressure applications.

These fittings are ready to install and include quick-clamp fittings, metal tubing, and Yor-Lok tube fittings at each end. The Yor-Lok fittings include a nut and two sleeves that grip your system’s stainless steel tubing. To complete the quick-clamp connection, you’ll need a clamp and ring (each sold separately).

For Tube | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Flange OD | High-Vacuum Flange Size | High Vacuum Connection Type | Connection Style | OD | Wall Thick. | Lg. | Max. Vacuum | Material | Each | |

For Use With Acetone, Air, Ammonium Hydroxide, Helium, Methane, Nitrogen, Oil, Water | ||||||||||

| 1.18" | 16 | ISO-KF | Yor-Lok | 1/4" | 0.028"-0.095" | 8" | 10 -8 torr @ 72° F | 304 Stainless Steel | 0000000 | 0000000 |

| 1.57" | 25 | ISO-KF | Yor-Lok | 1/4" | 0.028"-0.095" | 8" | 10 -8 torr @ 72° F | 304 Stainless Steel | 0000000 | 000000 |

| 2.16" | 40 | ISO-KF | Yor-Lok | 1/4" | 0.028"-0.095" | 8" | 10 -8 torr @ 72° F | 304 Stainless Steel | 0000000 | 000000 |

| 2.95" | 50 | ISO-KF | Yor-Lok | 1/4" | 0.028"-0.095" | 8" | 10 -8 torr @ 72° F | 304 Stainless Steel | 0000000 | 000000 |

| For Flange OD | For High-Vacuum Flange Size | High Vacuum Connection Type | Material | Max. Vacuum | Each | |

With Wing Nut | ||||||

|---|---|---|---|---|---|---|

| 1.18" | 10, 16 | ISO-KF | Aluminum | 10 -8 torr @ 72° F | 00000000 | 00000 |

| 1.57" | 25 | ISO-KF | Aluminum | 10 -8 torr @ 72° F | 0000000 | 00000 |

| 2.16" | 40 | ISO-KF | Aluminum | 10 -8 torr @ 72° F | 0000000 | 00000 |

| 2.95" | 50 | ISO-KF | Aluminum | 10 -8 torr @ 72° F | 0000000 | 00000 |

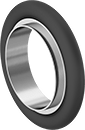

Material | |||||||

|---|---|---|---|---|---|---|---|

| For Flange OD | For High-Vacuum Flange Size | High Vacuum Connection Type | O-Ring | Inner Ring | Max. Vacuum | Each | |

| 1.18" | 16 | ISO-KF | Viton® Fluoroelastomer Rubber | 304 Stainless Steel | 10 -8 torr @ 72° F | 00000000 | 00000 |

| 1.57" | 25 | ISO-KF | Viton® Fluoroelastomer Rubber | 304 Stainless Steel | 10 -8 torr @ 72° F | 0000000 | 00000 |

| 2.16" | 40 | ISO-KF | Viton® Fluoroelastomer Rubber | 304 Stainless Steel | 10 -8 torr @ 72° F | 0000000 | 00000 |

| 2.95" | 50 | ISO-KF | Viton® Fluoroelastomer Rubber | 304 Stainless Steel | 10 -8 torr @ 72° F | 0000000 | 00000 |

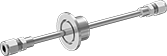

Flanged Through-Wall Fittings for Ultra-High-Vacuum Chambers

- For Use With: See table

- Environment Temperature Range: 32° to 300° F

- Process Temperature Range: -325° to 995° F

- Tubing: Use with 304/304L or 316/316L stainless steel

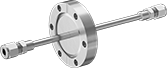

Bolt these fittings onto your ultra-high-vacuum chamber to transfer liquids and gases inside. Also known as feedthroughs, they come assembled with a flanged (CF) fitting, metal tubing, and two Yor-Lok tube fittings. Their bolt-together connection forms the tightest seal of any fitting type, so you can use them in semiconductor manufacturing, surface analysis experiments, and even research with particle accelerators. Made of stainless steel and copper, these fittings resist rusting. These fittings are not for use in pressure applications.

To complete the flanged connection, you’ll need a gasket and bolt kit (each sold separately). The Yor-Lok fittings on each end include a nut and two sleeves that grip your system’s stainless steel tubing.

Bolt Holes | For Tube | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Flange OD | High-Vacuum Flange Size | High Vacuum Connection Type | Bolt Circle Dia. | Dia. | No. of | Connection Style | OD | Wall Thick. | Lg. | Max. Vacuum | Material | Each | |

For Use With Acetone, Air, Ammonium Hydroxide, Helium, Methane, Nitrogen, Oil, Water | |||||||||||||

| 1 21/64" | 16 | CF | 1 1/16" | 11/64" | 6 | Yor-Lok | 1/4" | 0.028"-0.095" | 8" | 10 -13 torr @ 72° F | 304 Stainless Steel | 0000000 | 0000000 |

| 2 3/4" | 40 | CF | 2 5/16" | 17/64" | 6 | Yor-Lok | 1/4" | 0.028"-0.095" | 8" | 10 -13 torr @ 72° F | 304 Stainless Steel | 0000000 | 000000 |