How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

High-Pressure Brass Threaded Pipe Fittings

These fittings have the strength to handle high-pressure applications. They are brass for good corrosion resistance.

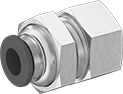

Through-wall fittings are also known as bulkhead couplings and panel-mount couplings; they mount through a wall or panel to create an inlet or outlet.

NPTF (Dryseal) threads are compatible with NPT threads.

- For Use With:

NPT Threads: Air, Water

NPTF, BSPP and Metric Threads: Air, Natural Gas, Oil, Water - Specifications Met: See table

| Pipe Size | Max. Pressure | Each | |

NPTF Female | |||

|---|---|---|---|

| 1 | 1,000 psi @ 72° F | 000000000 | 000000 |

Low-Pressure Stainless Steel Threaded Pipe Fittings

Use these fittings in a low-pressure pipe line. 316 stainless steel fittings have excellent corrosion resistance. Adapters with weld end allow for a permanent connection.

Adapters for tanks create an inlet or outlet connection on the surface of any tank, pressure vessel, or drum.

NPTF (Dryseal) threads and NPSL (National Pipe Straight Locknut) threads are compatible with NPT threads.

Low-Pressure Iron and Steel Threaded Pipe Fittings

Use these fittings for low-pressure applications in noncorrosive environments.

Adapters for tanks create an inlet or outlet connection on the surface of any tank, pressure vessel, or drum. Adapters with weld end allow for a permanent connection.

NPTF (Dryseal) threads, NPSC (National Pipe Straight Coupling) threads, and NPSL (National Pipe Straight Locknut) threads are compatible with NPT threads.

- For Use With: Diesel Fuel, Gasoline, Oil, Water

- Pipe Nipples and Pipe: Use Schedule 40 steel

| Pipe Size | For Hole Dia. | For Tank OD | OD | Lg. | Material | Each | |

NPTF Female × Weld | |||||||

|---|---|---|---|---|---|---|---|

| 3/4 | 1 1/8" | 20" | 2 3/16" | 7/16" | Steel | 0000000 | 00000 |

Low-Pressure Aluminum Threaded Pipe Fittings

In addition to being lightweight, these aluminum fittings offer good corrosion resistance. Use them in low-pressure flow applications. To prevent cracking, do not tighten more than a 1/4-turn past hand tight.

Adapters for tanks weld onto the surface of any tank, pressure vessel, or drum to create a permanent inlet or outlet connection. NPTF (Dryseal) threads and NPSL (National Pipe Straight Locknut) threads are compatible with NPT threads.

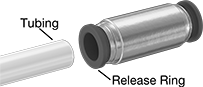

Brass Push-to-Connect Tube Fittings for Air

- Temperature Range: 0° to 200° F, except Tube Stem Straight Connectors are 0° to 150° F, and Plugs are 0° to 170° F

- Tubing: See table

These fittings offer good protection against corrosive environments. Also known as instant fittings, they connect to tubing with a push, and an internal gripping ring and O-ring hold the tubing tight. To disconnect, push on the release ring and pull the tubing out of the fitting.

Fittings with acrylic thread sealant offer extra protection against leaks.

NPTF (Dryseal) threads are compatible with NPT threads.

Through-wall fittings are also known as bulkhead couplings and panel-mount couplings; they mount through your wall or panel to create an inlet or outlet.

Release Ring | For Tube | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Pipe Size | Material | Material | Color | Max. Pressure | For Hole Dia. | For Max. Wall Thick. | Material | Hardness Rating | Features | Each | |

NPTF Threads | ||||||||||||

| 5/32" | 1/4 | Nickel-Plated Brass | Plastic | Black | 290 psi @ 72° F | 1/2" | 3/16" | Nylon Plastic, Polyethylene Plastic | Hard | Acrylic Thread Sealant | 000000000 | 000000 |

| 1/4" | 1/8 | Brass | Brass | __ | 250 psi @ 72° F | 9/16" | 1/2" | Nylon Plastic | Hard | __ | 000000000 | 00000 |

| 1/4" | 1/4 | Nickel-Plated Brass | Plastic | Black | 290 psi @ 72° F | 9/16" | 15/64" | Nylon Plastic, Polyethylene Plastic | Hard | Acrylic Thread Sealant | 000000000 | 00000 |

| 3/8" | 1/4 | Brass | Brass | __ | 250 psi @ 72° F | 7/8" | 11/16" | Nylon Plastic | Hard | __ | 000000000 | 00000 |

| 3/8" | 3/8 | Nickel-Plated Brass | Plastic | Black | 290 psi @ 72° F | 7/8" | 7/32" | Nylon Plastic, Polyethylene Plastic | Hard | Acrylic Thread Sealant | 000000000 | 00000 |

| 1/2" | 3/8 | Nickel-Plated Brass | Plastic | Black | 290 psi @ 72° F | 7/8" | 11/32" | Nylon Plastic, Polyethylene Plastic | Hard | Acrylic Thread Sealant | 000000000 | 00000 |

Plugs insert into the push-to-connect end of another fitting.

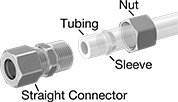

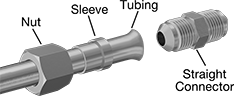

Brass Compression Tube Fittings for Air and Water

- For Use With: Air, Lubricated Air, Water

- Temperature Range: See table

- Tubing: Use with firm or hard (Durometer 1A-95A or Rockwell 15T 1-15T 60) nylon plastic, polyethylene plastic, polypropylene plastic or polyurethane rubber

- Specifications Met: SAE J512, except metric sizes

A single sleeve (ferrule) compresses the tubing as you tighten the nut, creating a strong seal. The nut and sleeve are included. Fittings are also known as flareless fittings. They are brass for good corrosion resistance.

Use tube supports (sold separately) when attaching fittings to plastic and rubber tubing to prevent the tube from collapsing.

NPTF (Dryseal) threads are compatible with NPT threads.

Straight adapters with smooth interior let you route tubing straight through one end of the fitting and out the other—there are no internal stops. They’re also known as straight-through tank fittings. To install, mount the fitting to the outside connection of a through-wall fitting (not included). Route the tubing through the fitting and tighten the nut to secure the tubing.

- Temperature Range:

Inch: -65° to 250° F

Metric: -40° to 250° F - Tubing:

Tube supports with 135 psi @ 75° F or 165 psi @ 75° F max. pressures: Use with firm or soft polyethylene plastic or PVC plastic

Tube supports with all other max. pressures: Use with firm or soft (Durometer 1A-95A) polyethylene plastic or polypropylene plastic

- For Use With:

Short nuts: Air, Water, Lubricated Air

Long nuts: Air, Water, Cutting Oil, Fuel Oil, Hydraulic Fluid, Mineral Oil - Temperature Range: See table

- Tubing:

Short nuts: Use with firm or hard (Durometer 1A-95A or Rockwell 15T 1-15T 60) nylon plastic, polyethylene plastic, polypropylene plastic, or polyurethane rubber

Long nuts: Use with firm or hard (Durometer 1A-95A) copper, nylon plastic, polyethylene plastic, polypropylene plastic, or polyurethane rubber - Specifications Met: See table

For Tube | |||||||

|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Nut Material | Max. Pressure | Temp. Range, °F | Specifications Met | Each | |

Short Nuts | |||||||

| 3/16" | 0.03" | Brass | 400 psi @ 72° F | -65° to 250° | SAE J512 | 000000000 | 00000 |

| 3/8" | 0.032" | Brass | 200 psi @ 72° F | -65° to 250° | SAE J512 | 000000000 | 0000 |

| 1/2" | 0.032" | Brass | 200 psi @ 72° F | -65° to 250° | SAE J512 | 000000000 | 0000 |

Long Nuts | |||||||

| 1/2" | 0.032" | Brass | 200 psi @ 72° F | -65° to 250° | UL Listed | 000000000 | 00000 |

- For Use With:

UL Listed sleeves: Air, Water, Cutting Oil, Fuel Oil, Hydraulic Fluid, Mineral Oil

All other sleeves: Air, Water, Lubricated Air - Temperature Range: See table

- Tubing:

UL Listed sleeves: Use with firm or hard (Durometer 1A-95A) copper, nylon plastic, polyethylene plastic, polypropylene plastic, or polyurethane rubber

All other sleeves: Use with firm or hard (Durometer 1A-95A or Rockwell 15T 1-15T 60) nylon plastic, polyethylene plastic, polypropylene plastic, or polyurethane rubber - Specifications Met: See table

For Tube | Sleeve | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Color | Max. Pressure | Temp. Range, °F | Specifications Met | Pkg. Qty. | Pkg. | |

| 3/16" | 0.03" | Brass | __ | 400 psi @ 72° F | -65° to 200° | UL Listed | 10 | 000000000 | 00000 |

| 3/8" | 0.032" | Acetal Plastic | White | 200 psi @ 72° F | -65° to 250° | SAE J512 | 10 | 000000000 | 0000 |

| 1/2" | 0.032" | Acetal Plastic | White | 200 psi @ 72° F | -65° to 250° | SAE J512 | 10 | 000000000 | 00000 |

| 1/2" | 0.032" | Brass | __ | 200 psi @ 72° F | -65° to 200° | UL Listed | 10 | 000000000 | 00000 |

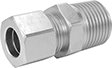

37° Flared Fittings for Steel Tubing

- For Use With: Air, Cutting Oil, Fuel Oil, Hydraulic Fluid, Mineral Oil

- Tubing: Use with seamless steel

- Specifications Met: SAE J514

Also known as JIC (Joint Industrial Council) fittings, these provide a tight metal-to-metal seal on tubing that is flared to 37°. They require a nut and a sleeve (ferrule) for each tube end. Nuts and sleeves are sold separately. Fittings are zinc-plated steel for fair corrosion resistance.

NPTF (Dryseal) threads are compatible with NPT threads.

- Temperature Range: -60° to 400° F

Through-wall fittings are also known as bulkhead couplings and panel-mount couplings; they mount through your wall or panel to create an inlet or outlet.

- Temperature Range: -60° to 400° F

Use these sleeves with a nut and fitting to provide a tight metal-to-metal seal on steel tubing that is flared to 37°. Sleeves are zinc-plated steel for fair corrosion resistance. They are also known as ferrules.