Filter by

System of Measurement

Capacity per Mount

Material

Height

Overall Height

Performance

Mounting Location

Deflection @ Capacity

Base Material

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Hardness Rating

Hardness

Minimum Temperature

Shock-Absorbing Spring Vibration-Damping Mounts

Vibration-Damping Mounts | Replacement Springs | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Base | Mounting | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style | Cap. per Mount, lb. | Thread Size | Thread Lg. | Deflection @ Cap. | Shear Cap. per Mount | Deflection @ Shear Cap. | Overall Ht. | Dia. | Lg. | Wd. | Color | Temp. Range, ° F | Fasteners Included | No. of Holes | Hole Dia. | Hole Ctr.-to-Ctr. | Base Material | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 100 | 3/8"-16 | 3/4" | 1" | Not Rated | Not Rated | 4.5" | 2 3/8" | — | — | Black | -40 to 180 | No | 1 | — | — | Iron | 00000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 150 | 3/8"-16 | 3/4" | 1" | Not Rated | Not Rated | 4.5" | 2 3/8" | — | — | Black | -40 to 180 | No | 1 | — | — | Iron | 00000000 | 00000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 250 | 3/8"-16 | 3/4" | 0.83" | Not Rated | Not Rated | 4.5" | 2 3/8" | — | — | Black | -40 to 180 | No | 1 | — | — | Iron | 00000000 | 00000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 300 | 3/8"-16 | 3/4" | 0.75" | Not Rated | Not Rated | 4.5" | 2 3/8" | — | — | Black | -40 to 180 | No | 1 | — | — | Iron | 00000000 | 00000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 50 | 3/8"-16 | 3" | 1" | Not Rated | Not Rated | 3.375" | — | 5.875" | 2.38" | Black | -20 to 180 | No | 2 | 0.438" | 5" | Iron | 0000000 | 00000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 100 | 3/8"-16 | 3" | 1" | Not Rated | Not Rated | 3.375" | — | 5.875" | 2.38" | Black | -20 to 180 | No | 2 | 0.438" | 5" | Iron | 0000000 | 00000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 150 | 3/8"-16 | 3" | 1" | Not Rated | Not Rated | 3.375" | — | 5.875" | 2.38" | Black | -20 to 180 | No | 2 | 0.438" | 5" | Iron | 0000000 | 00000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 190 | 1/2"-13 | 3 1/2" | 2.13" | Not Rated | Not Rated | 6.25" | — | 7.75" | 3" | Black | -40 to 180 | No | 2 | 0.625" | 6.5" | Iron | 00000000 | 000000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 250 | 3/8"-16 | 3" | 0.83" | Not Rated | Not Rated | 3.375" | — | 5.875" | 2.38" | Black | -20 to 180 | No | 2 | 0.438" | 5" | Iron | 0000000 | 00000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 300 | 3/8"-16 | 3" | 0.75" | Not Rated | Not Rated | 3.375" | — | 5.875" | 2.5" | Black | -40 to 180 | No | 2 | 0.438" | 5" | Iron | 00000000 | 00000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 370 | 3/8"-16 | 3" | 0.75" | Not Rated | Not Rated | 3.375" | — | 5.875" | 2.38" | Black | -20 to 180 | No | 2 | 0.438" | 5" | Iron | 0000000 | 00000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 520 | 3/8"-16 | 3" | 0.75" | Not Rated | Not Rated | 3.375" | — | 5.875" | 2.38" | Black | -20 to 180 | No | 2 | 0.438" | 5" | Iron | 0000000 | 00000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 675 | 1/2"-13 | 3 1/2" | 1.32" | Not Rated | Not Rated | 5.25" | — | 7.75" | 3" | Black | -20 to 180 | No | 2 | 0.625" | 6.5" | Iron | 0000000 | 000000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 765 | 1/2"-13 | 3 1/2" | 1.54" | Not Rated | Not Rated | 6.25" | — | 7.75" | 3" | Black | -40 to 180 | No | 2 | 0.625" | 6.5" | Iron | 00000000 | 000000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 900 | 1/2"-13 | 3 1/2" | 1.02" | Not Rated | Not Rated | 5.25" | — | 7.75" | 3" | Black | -20 to 180 | No | 2 | 0.625" | 6.5" | Iron | 0000000 | 000000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 1,200 | 1/2"-13 | 3 1/2" | 0.9" | Not Rated | Not Rated | 5.25" | — | 7.75" | 3" | Black | -20 to 180 | No | 2 | 0.625" | 6.5" | Iron | 0000000 | 000000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 1,785 | 1/2"-13 | 3 1/2" | 0.88" | Not Rated | Not Rated | 5.25" | — | 7.75" | 3" | Black | -20 to 180 | No | 2 | 0.625" | 6.5" | Iron | 0000000 | 000000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Door Stops for Sliding Doors

Style | Lg. | Wd. | Ht. | For Max. Door Wt., lb. | Material | Mounting Fasteners Included | Mounting Screw Size | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Unthreaded-Hole Mount | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 4 5/8" | 4 5/8" | 2 1/4" | 5,000 | Iron | No | No. 18 | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

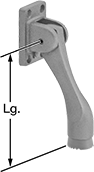

Lever-Operated Door-Mount Door Holders

Door Holders | Replacement Rubber Door Bumpers | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Material | Lg. | Door-to-Floor Clearance | Mounting Hardware Included | Specs. Met | Includes | Each | Pkg. Qty. | Pkg. | ||||

| 1 | Dull Aluminum-Coated Iron | 3 3/4" | 1/4" to 2" | Yes | ANSI/BHMA A156.16 | Nonmarring Rubber Pad | 0000000 | 000000 | 6 | 0000000 | 00000 | ||

| 1 | Dull Aluminum-Coated Iron | 4 3/4" | 1/4" to 3" | Yes | ANSI/BHMA A156.16 | Nonmarring Rubber Pad | 0000000 | 00000 | 6 | 0000000 | 0000 | ||

| 1 | Dull Brass-Plated Iron | 3 3/4" | 1/4" to 2" | Yes | ANSI/BHMA A156.16 | Nonmarring Rubber Pad | 0000000 | 00000 | 6 | 0000000 | 0000 | ||

| 1 | Dull Brass-Plated Iron | 4 3/4" | 1/4" to 3" | Yes | ANSI/BHMA A156.16 | Nonmarring Rubber Pad | 0000000 | 00000 | 6 | 0000000 | 0000 | ||

| 1 | Dull Bronze-Plated Iron | 3 3/4" | 1/4" to 2" | Yes | ANSI/BHMA A156.16 | Nonmarring Rubber Pad | 0000000 | 00000 | 6 | 0000000 | 0000 | ||

| 1 | Dull Bronze-Plated Iron | 4 3/4" | 1/4" to 3" | Yes | ANSI/BHMA A156.16 | Nonmarring Rubber Pad | 0000000 | 00000 | 6 | 0000000 | 0000 | ||

Easy-Install Vibration-Damping Swivel Leveling Mounts with Threaded Stud

With Rubber Cushion | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Thread Lg. | Swivel Range of Motion | Base Dia. | Cap. per Mount, lb. | Deflection @ Cap. | Overall Ht. | Cushion Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Iron Base and Zinc-Plated Steel Stud | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-24 | 3 1/2" | 3.5° | 2 1/2" | 250 | 0.04" | 4 1/4" | Buna-N | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-20 | 5 1/2" | 3.5° | 3 1/2" | 500 | 0.04" | 6 5/8" | Buna-N | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-20 | 5 1/2" | 3.5° | 3 1/2" | 1,000 | 0.04" | 6 5/8" | Buna-N | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-16 | 5 1/2" | 3.5° | 7" | 2,000 | 0.04" | 6 7/8" | Buna-N | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-16 | 5 1/2" | 3.5° | 7" | 4,000 | 0.04" | 6 7/8" | Buna-N | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-16 | 5 1/2" | 3.5° | 7" | 8,000 | 0.06" | 7" | Buna-N | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-16 | 5 1/2" | 3.5° | 7" | 12,000 | 0.06" | 7" | Buna-N | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Vibration-Damping Heavy Duty Rigid Leveling Mounts

Base | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cap. per Mount, lb. | Deflection @ Cap. | Surface Texture | Lg. | Wd. | Overall Ht. | Anchor Hole Dia. | Cushion Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Iron Base with Felt Cushion and Zinc-Plated Steel Bolt | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3,000 | 0.15" | Grooved | 3 9/16" | 6 1/16" | 1 7/8" to 2 1/8" | — | Felt | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9,000 | 0.15" | Grooved | 3 5/8" | 6" | 3" to 3 3/8" | — | Felt | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30,000 | 0.2" | Grooved | 3 1/2" | 6 3/4" | 3 1/2" to 3 3/4" | 1 1/8" | Felt | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Iron Base with Rubber Cushion and Zinc-Plated Steel Bolt | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15,000 | 0.09" | Grooved | 3 1/2" | 5 3/4" | 3 1/8" to 3 5/16" | 1" | SBR | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20,000 | 0.09" | Grooved | 3 1/2" | 6 3/4" | 3 1/2" to 3 3/4" | 1 1/8" | SBR | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Easy-Weld Wear Plates

Base | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wd. | Lg. | Overall Thk. | Thick. | Material | Score Interval | Hardness Rating | Hardness | For Use Outdoors | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Cast Iron | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 9 1/2" | 1" | 5/16" | Low-Carbon Steel | 1 1/2" | Extra Hard | Rockwell C64 | Yes | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 9 1/2" | 1" | 5/16" | Low-Carbon Steel | 1 1/2" | Extra Hard | Rockwell C64 | Yes | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 9 1/2" | 1" | 5/16" | Low-Carbon Steel | 1 1/2" | Extra Hard | Rockwell C64 | Yes | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 9 1/2" | 1" | 5/16" | Low-Carbon Steel | 1 1/2" | Extra Hard | Rockwell C64 | Yes | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||