Filter by

Shape

System of Measurement

Tip Style

REACH

RoHS

Shank Flexibility

DFARS Specialty Metals

Export Control Classification Number (ECCN)

For Use With

Tooth Style

Grit Rating

Sold As

Material

CNC-Mount Burs for Cross-Drilled Holes

Half Ball with Protective Ring

|  | |

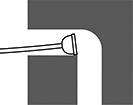

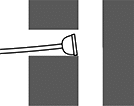

For Deburring L-Shaped Holes | For Deburring T-Shaped Holes | Single-Cut Tooth |

Head | Single-Cut Tooth (Fine Grit) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Shank Dia. | Dia. | Lg. | Overall Lg. | For Use On | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Carbide | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.03" | 1/16" | 1/32" | 2 1/2" | Steel, Hardened Steel, Tool Steel, Stainless Steel, Titanium, Iron, Nickel | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.03" | 3/32" | 1/16" | 2 1/2" | Steel, Hardened Steel, Tool Steel, Stainless Steel, Titanium, Iron, Nickel | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.045" | 1/8" | 3/32" | 4" | Steel, Hardened Steel, Tool Steel, Stainless Steel, Titanium, Iron, Nickel | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.061" | 3/16" | 1/8" | 4" | Steel, Hardened Steel, Tool Steel, Stainless Steel, Titanium, Iron, Nickel | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.093" | 1/4" | 5/32" | 6" | Steel, Hardened Steel, Tool Steel, Stainless Steel, Titanium, Iron, Nickel | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||