About Shaft Collars

Shaft collars are useful for holding and positioning components on a shaft. They can also serve as mechanical stops and stroke limiters.

More

Stainless Steel Helical Inserts

Also known as Heli-Coil inserts, these inserts have coils that expand once installed to securely anchor the insert. All have a prong for ease of installation. An installation tool grips the prong and reduces the coil diameter, enabling the insert to fit in tapped holes. Remove the prong to insert the screw. Installation requires a drill bit, a helical insert tap, an installation tool, and a prong break-off tool.

Helical Inserts with Installation Tools

Inserts come with a through-hole tap and installation tool. Also known as Heli-Coil inserts, they have coils that expand once installed to securely anchor the insert. All have a prong for ease of installation. An installation tool grips the prong and reduces the coil diameter, enabling the insert to fit in tapped holes. Remove the prong to insert the screw.

| Thread Size | Installed Lg. | Drill Bit Size | For Max. Hole Dia. | No. of Inserts Included | Includes | Each | |

18-8 Stainless Steel—Right-Hand Threaded | |||||||

|---|---|---|---|---|---|---|---|

| 1 1/2"-12 | 2 1/4" | 1 17/32" | 1 17/32" | 4 | Drill Bit, Through-Hole Tap, Installation Tool | 000000000 | 000000000 |

Black-Phosphate Steel Key-Locking Inserts

A black-phosphate finish provides mild corrosion resistance. Drive the keys into the surrounding material for a more secure hold than thread-locking inserts. Use them to repair or change threads in soft metals such as aluminum. They’re comparable to Keensert inserts. Installation requires a drill bit, a standard tap, an installation tool, and a hammer.

Choose inserts with a thick wall for greater strength than thin-wall inserts, or to fill a large hole with stripped threads.

Inserts with an extra thick wall are stronger than thick- and thin-wall inserts. Use them to reduce the size of tapped holes.

Inserts | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Each | Installation Tools | |||||||||

| Thread Size | For Tap Thread Size | Installed Lg. | Drill Bit Size | For Max. Hole Dia. | No. of Locking Keys | 1-9 | 10-Up | Each | ||

Black-Phosphate Steel with Thick Wall | ||||||||||

| 1 1/8"-7 | 1 1/2"-12 | 1 5/8" | 1 7/16" | 1 7/16" | 4 | 000000000 | 000000 | 000000 | 000000000 | 0000000 |

| 1 1/8"-12 | 1 1/2"-12 | 1 5/8" | 1 7/16" | 1 7/16" | 4 | 000000000 | 00000 | 00000 | 000000000 | 000000 |

| 1 1/2"-12 | 1 7/8"-12 | 2" | 1 13/16" | 1 13/16" | 4 | 000000000 | 000000 | 000000 | 000000000 | 000000 |

Black-Phosphate Steel with Extra Thick Wall | ||||||||||

| 1"-8 | 1 1/2"-12 | 1 3/8" | 1 7/16" | 1 7/16" | 4 | 000000000 | 00000 | 00000 | 000000000 | 00000 |

18-8 Stainless Steel Key-Locking Inserts

Made of stainless steel, these inserts have good corrosion resistance. Drive the keys into the surrounding material for a more secure hold than thread-locking inserts. Use them to repair or change threads in soft metals such as aluminum. Inserts may be mildly magnetic. They’re comparable to Keensert inserts. Installation requires a drill bit, a standard tap, an installation tool, and a hammer.

Inserts with an extra-thick wall are stronger than thick- and thin-wall inserts. Use them to reduce the size of tapped holes.

Mil. Spec. 18-8 Stainless Steel Key-Locking Inserts

These inserts are made to stringent military specifications. Drive the keys into the surrounding material for a more secure hold than thread-locking inserts. Use them to repair or change threads in soft metals such as aluminum. Inserts may be mildly magnetic. They’re comparable to Keensert inserts. Installation requires a drill bit, a standard tap, an installation tool, and a hammer.

Inserts with a thin wall are often used in small holes or near the edge of a workpiece.

Choose inserts with a thick wall for greater strength than thin-wall inserts, or to fill a large hole.

Key-Locking Inserts with Installation Tool

Drive the keys into the surrounding material for a more secure hold than thread-locking inserts. These inserts are used to repair or convert threads in soft metals such as aluminum. They’re comparable to Keensert inserts.

Black-phosphate steel inserts are mildly corrosion resistant.

Choose inserts with a thick wall for greater strength than thin-wall inserts, or to fill a large hole.

| Thread Size | For Tap Thread Size | Installed Lg. | Drill Bit Size | For Max. Hole Dia. | No. of Locking Keys | No. of Inserts Included | Each | |

Black-Phosphate Steel with Thick Wall | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1 1/8"-7 | 1 1/2"-12 | 1 5/8" | 1 7/16" | 1 7/16" | 4 | 2 | 000000000 | 0000000 |

Threaded Shaft Collars

To install, thread these one-piece collars onto the end of your shaft. They clamp evenly around the shaft to create a strong, mar-free hold. Tighten the clamping screw to secure.

Black-oxide steel collars have some corrosion resistance. 303 stainless steel collars have excellent corrosion resistance.

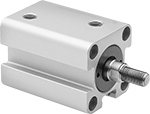

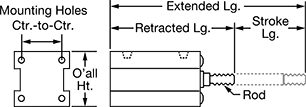

Compact Hydraulic Cylinders

With a small body size, these cylinders fit into tight spaces but offer similar push forces to standard hydraulic cylinders. They’re double-acting cylinders, so they have two hydraulic ports—one to extend the piston rod and another to retract it. No matter the direction they’re moving, they can operate at nearly full force. This allows them to both push and pull multi-ton loads. All have a magnetic piston and can be used with sensors (sold separately) that electronically indicate piston position. Mount sensors to the cylinder with mounting brackets (sold separately).

O'all | Mounting Holes | Inlet/Outlet Connection— NPT | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Stroke Lg. | Max. Push Force, lbs. | Max. Pull Force, lbs. | Retracted Lg. | Extended Lg. | Rod Thread Size | Wd. | Ht. | Ctr.-to-Ctr. | Dia. | Pipe Size | Dash Size | Body Material | Max. Pressure, psi | Air Cushion Type | Each | |

4" Bore Dia. | ||||||||||||||||

| 1" | 28,240 | 19,380 | 8 1/8" | 9 1/8" | 1 1/2"-12 | 5 3/4" | 5 3/4" | 4 3/16" | 21/32" | 3/8 | 06 | Aluminum | 2,300 | No Cushion | 0000000 | 0000000 |

| 2" | 28,240 | 19,380 | 9 1/8" | 11" | 1 1/2"-12 | 5 3/4" | 5 3/4" | 4 3/16" | 21/32" | 3/8 | 06 | Aluminum | 2,300 | No Cushion | 0000000 | 000000 |

| 3" | 28,240 | 19,380 | 10 1/8" | 13" | 1 1/2"-12 | 5 3/4" | 5 3/4" | 4 3/16" | 21/32" | 3/8 | 06 | Aluminum | 2,300 | No Cushion | 0000000 | 000000 |

| AC Voltage | DC Voltage | Solid State Output | With Switch Component | Each | |

Reed Switch—for 1", 1 1/4", 1 1/2", 2", 2 1/2", 3", 4" Bore Dia. | |||||

|---|---|---|---|---|---|

| 24V AC, 48V AC, 100V AC | 24V DC, 48V DC, 100V DC | __ | __ | 00000000 | 000000 |

| __ | 24V DC, 100V DC | __ | LED | 00000000 | 00000 |

Solid State Switch—for 1", 1 1/4", 1 1/2", 2", 2 1/2", 3", 4" Bore Dia. | |||||

| __ | 24V DC | NPN | LED | 00000000 | 00000 |

| __ | 24V DC | PNP | LED | 00000000 | 00000 |

| For Bore Dia. | For Sensor Type | Material | Includes | Each | |

| 1 1/2", 2", 2 1/2", 3", 4" | Solid State Switch, Reed Switch | Zinc | Set Screw | 0000000 | 00000 |