Filter by

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Roller Material

Cable Bender Type

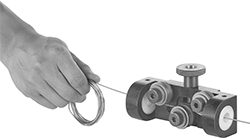

Miniature Wire Benders

Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Max. Wire Dia. | Material | Lg. | Wd. | Ht. | Mounting Fasteners Included | No. of | Dia. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Aluminum, Brass, Copper, Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | Aluminum | 4 3/8" | 1" | 3/4" | Yes | 2 | 3/8" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Benders

For Max. Flat Stock | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Die Dia. | For Max. Wire Dia. | Thk. | Wd. | For Max. Rod Dia. | Material | Lg. | Wd. | Ht. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Brass, Copper, Stainless Steel, and Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4", 1 1/4", 1 5/8" | 1/2" | 1/4" | 1" | 1/2" | Steel | 20" | 2" | 5" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

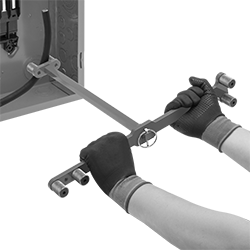

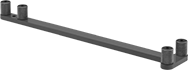

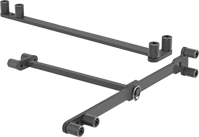

Cable Benders

|  |

Two Benders Used at Once | Benders Used with T-Handle Configuration |

|  |

Style A (Wrench Sold Separately) | Style B |

|  |

Style C | Style D |

For Wire | Cable Bender | Handle | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Max. Dia. | Max. Ga. | No. Included | Type | Includes | Square Drive Size | Lg. | Wd. | Ht. | Lg. | Material | Material | Each | ||

| A | 0.938" | 500 MCM | 1 | For Ratchet Wrench | 2 Knurled Dies | 1/2" | 3" | 1 1/2" | 1 1/2" | — | — | Aluminum | 0000000 | 000000 | |

| B | 0.625" | 4/0 | 1 | Straight | 4 Smooth Dies | — | — | — | — | 14" | Steel | — | 0000000 | 000000 | |

| B | 0.938" | 500 MCM | 1 | Straight | 4 Smooth Dies, 4 Knurled Dies | — | — | — | — | 18" | Steel | — | 0000000 | 000000 | |

| C | 0.625" | 4/0 | 1 1 | Straight T-Handle Adapter | 6 Smooth Dies | — | — | — | — | 14" | Steel | — | 0000000 | 000000 | |

| C | 0.938" | 500 MCM | 1 1 | Straight T-Handle Adapter | 6 Smooth Dies, 6 Knurled Dies | — | — | — | — | 18" | Steel | — | 0000000 | 000000 | |

| D | 1.094" | 750 MCM | 2 1 | Straight T-Handle Adapter | 10 Smooth Dies, 10 Knurled Dies | — | — | — | — | 22" | Steel | — | 0000000 | 000000 | |

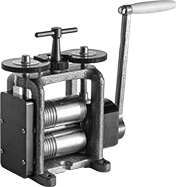

Benchtop Rolling Mills

Manual

For Max. Steel | Roller | Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wd. | Thk. | Square Wire Size | Half-Round Wire Size | Gear Speed Ratio | Ht. | Wd. | Dp. | Handle Lg. | Dia. | No. of | Material | Frame Material | Mounting Fasteners Included | No. of | Dia. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Aluminum, Brass, Stainless Steel, Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 9/16" | 3/16" | 3/64", 5/64", 1/8", 5/32", 3/16", 13/64", 7/32", 15/64", 1/4" | 0.098", 0.118", 0.157" | 4:1 | 14" | 12" | 8" | 12" | 2 1/2" | 2 | Steel | Cast Iron | No | 6 | 3/8" | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

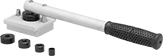

Economy Benders

Wire, Rod, and Flat Stock Curvers

|  |

Curver | Curver with Stand |

For Max. Flat Stock | Stand | Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Wire Dia. | Thk. | Wd. | For Rod Dia. | Min. Bending Radius | Material | Ht. | Wd. | Dp. | Handle Lg. | Roller Dia. | Ht. | Wd. | Dp. | Mounting Fasteners Included | No. of | Dia. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Aluminum, Brass, Copper, Stainless Steel, and Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 3/16" | 1" | 1/4" | 1 1/2" | Steel | 5 1/2" | 6 1/2" | 5 1/2" | 13 1/2" | 1 1/4" | — | — | — | No | 2 | 3/8" | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4", 1/2" | 3/16" | 1" | 1/4", 1/2" | 1 3/8" | Steel | 6 3/4" | 5 1/2" | 9 3/4" | 9" | 1 13/16" | 39" | 21" | 21" | Yes | 2 | 5/16" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Wire Straighteners

Roller | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Max. Wire Dia. | Lg. | Wd. | Ht. | Material | Dia. | No. of | Heat Treatment | Material | Adjustment Mechanism | Features | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Aluminum, Brass, Copper, Stainless Steel, Steel, and Titanium | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.052" | 5 1/2" | 2" | 3" | Aluminum | 1 3/16" | 3 | Hardened | Tool Steel | Knob | Acetal Plastic Wire Guides | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.188" | 5 1/2" | 2" | 3" | Aluminum | 1 3/16" | 3 | Hardened | Tool Steel | Knob | Acetal Plastic Wire Guides | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

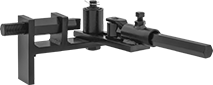

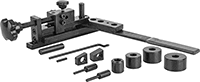

Wire, Rod, and Flat Stock Bender for Complex Shapes

For Max. Flat Stock | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Max. Wire Dia. | Thk. | Wd. | For Max. Rod Dia. | Material | Lg. | Wd. | Ht. | Handle Lg. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Brass, Copper, Stainless Steel, and Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.3125" | 0.125" | 1" | 0.3125" | Steel | 9.5" | 2.5" | 3.5" | 12" | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||