Filter by

Wire Rope Diameter

Fitting Type

For Sleeve Type

Application

Wire Rope Material

Sleeve Material

Sleeve Length

Wire Rope Construction

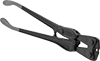

Required Installation Tool

Thread Size

Weight Capacity

Length

Eye ID

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Material Handling

Electrical