Filter by

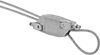

Attachment Type

Wire Rope Diameter

Length

Fitting Type

Application

Flexibility

Weight Capacity

Eye Thickness

Loop Inside Width

Loop Inside Length

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Eye Material

End-to-Eye Length

Sleeve Material

Coating Material