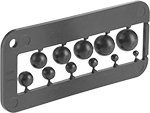

Calibration Kit for Metal-Detectable Plastics

Made with metal additives, these balls test the sensitivity of food-processing metal detectors. They’re often used to calibrate metal detectors to find metal-detectable plastic tools that have fallen into a batch. To calibrate your metal detector, run different balls through the line—the smaller the ball, the more sensitive the detector must be to recognize it. Since they’re spheres, their orientation won’t affect a metal detector’s ability to register them. These balls help you comply with Hazard and Critical Control Point (HACCP) programs for food safety. They’re FDA compliant for direct contact with food. Balls are autoclavable, so you can sanitize them with steam.

| Material | Color | Max. Temperature, °F | Autoclavable | Includes | Specifications Met | Each | |

| Polypropylene Plastic | Blue | 180° | Yes | Sizes 4 mm to 14 mm (1 mm increments) | FDA Compliant 21 CFR 177.1520 | 0000000 | 00000 |

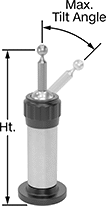

Calibration Spheres for CMMs

Test your coordinate measuring machine (CMM) probe and stylus against a precise reference point before you start inspecting. These spheres come with a calibration certificate traceable to UKAS (United Kingdom Accreditation Service) that confirms their accuracy. Made of tungsten carbide, they won’t lose their precise shape or size over time.

To prepare your probe for different inspection angles, adjust the angle of the sphere. For example, if you need to measure underneath a part, angle these spheres down to 45°. They rotate 360° even when angled. They snap into place when they’re perfectly vertical, the most common position. After you’ve positioned these spheres how you want, lock them in place by tightening the collar. Each time you adjust the sphere, you’ll need to recalibrate your probe and stylus.

Smaller spheres are best for probes with smaller stylus ends. As a rule of thumb, you should use the 25 mm dia. sphere for any stylus with an end diameter over 2 mm.

Mounting studs (sold separately) are required to mount to your CMM’s table or to a quick-change fixture plate. These plates take the work out of threading a sphere in and out of your table every time you calibrate.

Ball | Base | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dia., mm | Sphericity Tolerance, mm | Dia. Tolerance, mm | Material | Ht., mm | Dia., mm | Material | Rotation | Max. Tilt Angle | Certification | Container Type | Each | |

| 12 | -0.0001 to 0.0001 | -0.001 to 0.001 | Tungsten Carbide | 156-173 | 57 | Aluminum | 360° | 45° | Calibration Certificate with Test Data Traceable to UKAS | Plastic Case | 0000000 | 0000000 |

| 25 | -0.0001 to 0.0001 | -0.001 to 0.001 | Tungsten Carbide | 156-173 | 57 | Aluminum | 360° | 45° | Calibration Certificate with Test Data Traceable to UKAS | Plastic Case | 0000000 | 000000 |

Quick-Change Fixture Plates

Snap these magnetic plates in and out of the mounting rail as swappable stages for measuring and inspecting parts. Unlike standard fixture plates that you need to bolt or clamp down, these quickly attach and release, creating a hub of plates that are locked and loaded. As your coordinate measuring machine (CMM) works in the background, position your next workpiece on another plate so it’s ready to switch out for the next run. If you need more room to inspect parts, combine plates in a chain to extend your surface. While they’re not sturdy enough for use in machining, you can use them for light fabrication work, such as laser engraving.

When docked on a rail, the strong magnets in these plates hold them still. The lightweight aluminum makes them easy to lift and swap, and an anodized coating protects them from scratches and wear, even if you’re working with heavy parts.

Plates for calibration spheres take the work out of threading a sphere in and out of your table every time you calibrate your CMM. Move them off to the side when you’re not calibrating to prevent the probe of your CMM from crashing into the sphere. Keeping your sphere up and out of the way instead of stored in a drawer protects it from scrapes and bumps.