Ball-Grip Positioning Arms

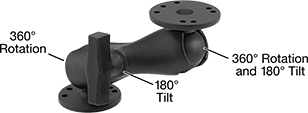

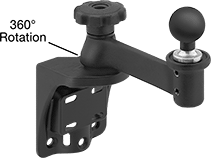

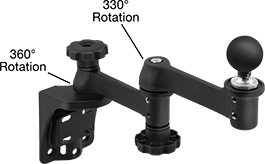

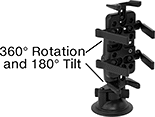

Ball-and-socket connections allow 360° positioning. Choose a complete arm or select a base, connectors, and accessories to build your own.

To ensure compatibility, select components that have the same ball diameter. Use reducing connectors (sold separately) to pair components with a 1 1/2" ball diameter to those with a 1" ball diameter.

For technical drawings and 3-D models, click on a part number.

Rotating and rotating/tilting complete arms have handles to lock joints into position. Rotating/tilting complete arms mount to a bench or a wall. Secure the object you want to position to the attaching end plate.

Any-which-way complete arms bend and stay in position. They do not have a ball; affix a screw-on base (sold separately) to attach to a connector.

To see the product in motion, click on a part number.

Base | Attaching End | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mount. Location | Max. Projection | Ht. | Ball Dia. | Max. Load Capacity, lbs. | Material | Ball Material | Mount. Fasteners Included | Dia. | Lg. | Wd. | No. of Mount. Holes | Mount Hole Dia. | Plate Dia. | Mount. Hole Dia. | Each | |

Rotating/Tilting | ||||||||||||||||

| Bench, Wall | 7 1/4" | __ | __ | 3 | Powder-Coated Aluminum | __ | No | 2 7/16" | __ | __ | 7 | 3/16" | 2 7/16" | 3/16" | 0000000 | 000000 |

Rotating with Ball | ||||||||||||||||

| Wall | 9 1/4" | 9" | 1 1/2" | 3 | Powder-Coated Aluminum | Rubber | No | __ | 4 3/4" | 3 7/8" | 6 | 11/32" | __ | __ | 0000000 | 000000 |

Extended-Reach Rotating with Ball | ||||||||||||||||

| Wall | 15 1/4" | 11 1/4" | 1 1/2" | 3 | Powder-Coated Aluminum | Rubber | No | __ | 4 3/4" | 3 7/8" | 6 | 11/32" | __ | __ | 0000000 | 000000 |

Rotating/Tilting with Ball | ||||||||||||||||

| Bench, Wall | 14 1/2" | 14 1/2" | 1 1/2" | 3 | Powder-Coated Aluminum | Rubber | No | __ | 3 7/16" | 3 7/16" | 4 | 11/32" | __ | __ | 0000000 | 000000 |

Any-Which-Way | ||||||||||||||||

| Bench, Wall | __ | 7 3/8" | __ | 1 | Plastic | __ | No | 2 1/2" | __ | __ | 4 | 13/64" | 2 1/2" | 13/64" | 00000000 | 00000 |

Style A bases have a handle to quickly grip or release pipes.

Base | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Style | Clamping Range | Ht. | Ball Dia. | Max. Load Capacity, lbs. | Material | Ball Material | Lg. | Wd. | Each | |

Rectangular-Bar Mount | ||||||||||

| D | 0"-2 1/2" | 2 1/2" | 1 1/2" | 3 | Powder-Coated Aluminum | Rubber | 3 1/8" | 1 1/4" | 0000000 | 000000 |

| Mount. Location | Ht. | Ball Dia. | Max. Load Capacity, lbs. | Material | Ball Material | Base Dia. | Each | |

| Bench, Wall | 2 1/4" | 1 1/2" | 0.5 | Aluminum | Rubber | 2 1/2" | 0000000 | 000000 |

Reducing connectors join components with a 1 1/2" ball diameter to those with a 1" ball diameter. They have handles to lock the joints into position.

| Lg. | For Ball Dia. | Max. Load Capacity, lbs. | Material | Each | |

| 5 1/4" | 1"; 1 1/2" | 1 | Plastic | 00000000 | 000000 |

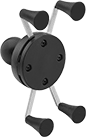

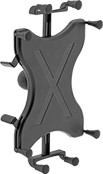

Hand-held device grips adjust for a secure hold.

Styles E and F have spring-loaded fingers that you can adjust to fit devices of different sizes. Rubber caps on the fingers create a tight grip on your smartphone or tablet.

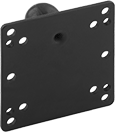

Flat-panel monitor mounting plates have a VESA standard mounting hole pattern to attach monitors, tablet holders, and other devices.

Mounting plates for monitors and keyboards do not have a ball; affix a screw-on base (sold separately) to attach to a connector.

Mount. | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Mount. | Wd. | Ht. | Ball Dia. | Max. Load Capacity, lbs. | Material | Ball Material | Fasteners Included | Monitor Hole Pattern Compatibility | Each | |

| Monitor | 4 3/4" | 4 3/4" | 1 1/2" | 3 | Powder-Coated Aluminum | Rubber | No | VESA 100, VESA 75 | 0000000 | 000000 |

Magnetic trays keep fasteners and other small steel items in place. They do not have a ball; affix a screw-on base (sold separately) to attach to a connector.

Mount. | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Lg. | Wd. | For Ball Dia. | Max. Load Capacity, lbs. | Material | Fasteners Included | No. of Holes | Hole Dia. | Each | |

| 10" | 13" | 1 1/2" | 1 | Plastic | No | 4 | 11/64" | 00000000 | 000000 |

Heavy Duty Ball-Grip Positioning Arms

With strength for higher load capacities than other ball-grip positioning arms, these arms have a heavy duty construction. Ball-and-socket connections allow 360° positioning. The base, connectors, and links are hollow for routing wires, cables, and small hoses. Select a base, connectors, link, and plate or mount to build a complete arm.

For technical drawings and 3-D models, click on a part number.

Base is for use with straight and tee connectors.

For T-Slot Rail | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Ht. | Style | Dia. | ID | Lg. | Max. Load Capacity, lbs. | Material | Color | Mount. Fasteners Included | Each | |

| 1", 1 1/2" | Single | 2 1/2" | 7/8" | 2 1/2" | 35 | Anodized Aluminum | Blue | Yes | 0000000 | 000000 |

Mounting plates require a base and a straight or tee connector to attach to a link. Blank mounting plate allows you to drill custom mounting holes.

| Lg. | Wd. | Max. Load Capacity, lbs. | Material | Color | Mount. Fasteners Included | Each | |

| 4 5/16" | 2 1/2" | 35 | Anodized Aluminum | Blue | Yes | 0000000 | 000000 |

Mounting plates require a base and a straight or tee connector to attach to a link. Flat-panel monitor mounting plate has a VESA (Video Electronics Standards Association) standard mounting hole pattern.

Mount. | ||||||||

|---|---|---|---|---|---|---|---|---|

| Lg. | Wd. | Max. Load Capacity, lbs. | Material | Color | Fasteners Included | Hole Pattern Compatibility | Each | |

| 4 1/2" | 4 1/2" | 35 | Anodized Aluminum | Blue | Yes | VESA 100, VESA 75 | 0000000 | 000000 |

Sensor mounts are threaded for sensors. They have sight holes so you can view indicator lights.

Locking handle can be used with straight and tee connectors to lock joints in place to restrict movement.

Mount. Stud | ||||||

|---|---|---|---|---|---|---|

| Lg. | Material | Color | Thread Size | Lg. | Each | |

| 2" | Steel | Black | 10-24 | 1" | 0000000 | 000000 |

Any-Which-Way Positioning Arms

Bend these arms to hold small equipment such as lights and microphones in almost any position.

For technical drawings and 3-D models, click on a part number.

Use threaded stud and threadlocker to convert a threaded hole into a threaded stud.

| Max. Projection | Attaching End Mount. Thread Size | Base Mount. Thread Size | Max. Load Capacity, lbs. | Material | Color | Includes | Each | |

Threaded Hole/Threaded Stud Attaching End | ||||||||

|---|---|---|---|---|---|---|---|---|

| 6" | 1/4"-20 | 1/4"-20 | 4 | Vinyl-Coated Steel | Black | Two 1/4"-20 Threaded Studs, Threadlocker | 00000000 | 000000 |

| 9" | 1/4"-20 | 1/4"-20 | 3.5 | Vinyl-Coated Steel | Black | Two 1/4"-20 Threaded Studs, Threadlocker | 00000000 | 00000 |

| 12" | 1/4"-20 | 1/4"-20 | 3 | Vinyl-Coated Steel | Black | Two 1/4"-20 Threaded Studs, Threadlocker | 00000000 | 00000 |

| 15" | 1/4"-20 | 1/4"-20 | 2.5 | Vinyl-Coated Steel | Black | Two 1/4"-20 Threaded Studs, Threadlocker | 00000000 | 00000 |

| 18" | 1/4"-20 | 1/4"-20 | 2.5 | Vinyl-Coated Steel | Black | Two 1/4"-20 Threaded Studs, Threadlocker | 00000000 | 00000 |

| 24" | 1/4"-20 | 1/4"-20 | 1.5 | Vinyl-Coated Steel | Black | Two 1/4"-20 Threaded Studs, Threadlocker | 00000000 | 00000 |

| 30" | 1/4"-20 | 1/4"-20 | 0.8 | Vinyl-Coated Steel | Black | Two 1/4"-20 Threaded Studs, Threadlocker | 00000000 | 00000 |

| 36" | 1/4"-20 | 1/4"-20 | 0.6 | Vinyl-Coated Steel | Black | Two 1/4"-20 Threaded Studs, Threadlocker | 00000000 | 00000 |

| Max. Projection | Attaching End Mount. Thread Size | Attaching End Mount. Pipe Size | Base Mount. Thread Size | Base Mount. Pipe Size | Max. Load Capacity, lbs. | Material | Color | Each | |

Threaded Hole Attaching End | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 6" | 5/8"-27 | __ | 5/8"-27 | __ | 3 | Vinyl-Coated Steel | Black | 000000000 | 00000 |

| 13" | 5/8"-27 | __ | 5/8"-27 | __ | 1 | Vinyl-Coated Steel | Black | 000000000 | 00000 |

| 19" | 5/8"-27 | __ | 5/8"-27 | __ | 1 | Vinyl-Coated Steel | Black | 000000000 | 00000 |

Threaded Stud Attaching End | |||||||||

| 9" | __ | 1/8 | __ | 1/8 | 2 | Vinyl-Coated Steel | Black | 000000000 | 0000 |

| 15" | __ | 1/8 | __ | 1/8 | 1 | Vinyl-Coated Steel | Black | 000000000 | 0000 |

| 24" | __ | 1/8 | __ | 1/8 | 1 | Vinyl-Coated Steel | Black | 000000000 | 00000 |

Hole/Threaded

Stud Attaching End

Use threaded stud and threadlocker to convert a threaded hole into a threaded stud.

Base | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Projection | Attaching End Mount. Thread Size | Mount. Fasteners Included | No. of Mount. Holes | Mount. Hole Dia. | Lg. | Wd. | Max. Load Capacity, lbs. | Material | Color | Includes | Each | |

| 9" | 1/4"-20 | No | 2 | 0.275" | 2" | 1" | 3.5 | Vinyl-Coated Steel | Black | One 1/4"-20 Threaded Stud, Threadlocker | 00000000 | 000000 |

| 9" | 3/8"-16 | Yes | 2 | 0.275" | 2" | 1" | 3 | Vinyl-Coated Steel | Black | One 3/8"-16 Threaded Stud, Threadlocker | 00000000 | 00000 |

| 16" | 1/4"-20 | No | 2 | 0.275" | 2" | 1" | 2.5 | Vinyl-Coated Steel | Black | One 1/4"-20 Threaded Stud, Threadlocker | 00000000 | 00000 |

| 16" | 3/8"-16 | No | 2 | 0.275" | 2" | 1" | 2.5 | Vinyl-Coated Steel | Black | One 3/8"-16 Threaded Stud, Threadlocker | 00000000 | 00000 |

| 24" | 1/4"-20 | No | 2 | 0.275" | 2" | 1" | 1.5 | Vinyl-Coated Steel | Black | One 1/4"-20 Threaded Stud, Threadlocker | 00000000 | 00000 |

| 24" | 3/8"-16 | No | 2 | 0.275" | 2" | 1" | 1.5 | Vinyl-Coated Steel | Black | One 3/8"-16 Threaded Stud, Threadlocker | 00000000 | 00000 |

Arms with padded base clamp have plastic pads that protect mounting surfaces from marring.

Where included, use threaded stud and threadlocker to convert a threaded hole into a threaded stud.

Base | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Projection | Attaching End Mount. Thread Size | Lg. | Wd. | For Max. Mount. Surface Thick. | Max. Load Capacity, lbs. | Material | Color | Includes | Features | Each | |

Threaded Hole Attaching End | |||||||||||

| 16" | 3/8"-16 | 2" | 2" | 2" | 2.5 | Vinyl-Coated Steel | Black | __ | Padded Base Clamp | 00000000 | 000000 |

| 24" | 3/8"-16 | 2" | 2" | 2" | 1.5 | Vinyl-Coated Steel | Black | __ | Padded Base Clamp | 00000000 | 00000 |

Threaded Hole/Threaded Stud Attaching End | |||||||||||

| 9" | 1/4"-20 | 2 7/8" | 2" | 2" | 3.5 | Vinyl-Coated Steel | Black | One 1/4"-20 Threaded Stud, Threadlocker | __ | 00000000 | 00000 |

| 9" | 3/8"-16 | 2" | 1 5/8" | 2" | 3 | Vinyl-Coated Steel | Black | One 3/8"-16 Threaded Stud, Threadlocker | Padded Base Clamp | 00000000 | 00000 |

| 16" | 1/4"-20 | 2 7/8" | 2" | 2" | 2.5 | Vinyl-Coated Steel | Black | One 1/4"-20 Threaded Stud, Threadlocker | __ | 00000000 | 00000 |

| 24" | 1/4"-20 | 2 7/8" | 2" | 2" | 1.5 | Vinyl-Coated Steel | Black | One 1/4"-20 Threaded Stud, Threadlocker | __ | 00000000 | 00000 |

Where included, use threaded stud and threadlocker to convert a threaded hole into a threaded stud.

| Max. Projection | Attaching End Mount. Thread Size | Base Dia. | Max. Pull, lbs. | Max. Load Capacity, lbs. | Material | Color | Includes | Each | |

Threaded Hole Attaching End | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 16" | 3/8"-16 | 3" | 100 | 2.5 | Vinyl-Coated Steel | Black | __ | 00000000 | 000000 |

| 25" | 3/8"-16 | 3" | 100 | 1.5 | Vinyl-Coated Steel | Black | __ | 00000000 | 00000 |

Threaded Hole/Threaded Stud Attaching End | |||||||||

| 9" | 1/4"-20 | 3 1/4" | 100 | 3.5 | Vinyl-Coated Steel | Black | One 1/4"-20 Threaded Stud, Threadlocker | 00000000 | 00000 |

| 9" | 3/8"-16 | 3" | 100 | 3 | Vinyl-Coated Steel | Black | One 3/8"-16 Threaded Stud, Threadlocker | 00000000 | 00000 |

| 16" | 1/4"-20 | 3 1/4" | 100 | 2.5 | Vinyl-Coated Steel | Black | One 1/4"-20 Threaded Stud, Threadlocker | 00000000 | 00000 |

| 24" | 1/4"-20 | 3 1/4" | 100 | 1.5 | Vinyl-Coated Steel | Black | One 1/4"-20 Threaded Stud, Threadlocker | 00000000 | 00000 |

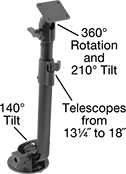

Portable Positioning Arms

A suction base makes it easy to move and attach these arms to smooth surfaces such as glass and polished metal. Secure the object you want to position to the attaching end. All arms have handles to lock joints into position.

Style A telescopes and has a universal AMPS mounting hole pattern.

To see the product in motion, click on a part number.

For technical drawings and 3-D models, click on a part number.

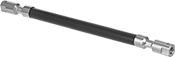

Bend-and-Stay Positioning Arms

Stronger and with greater load capacities than gooseneck-style positioning arms, these arms keep their shape even when moving or when exposed to vibration. They’re often used in robotics and conveyor applications when frequent repositioning isn’t required.

All accessories include the necessary hardware for attaching them to arms.

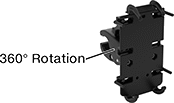

Ball-and-socket adapters and ball-and-socket connectors allow 360° rotation and up to 90° tilt. A locking knob keeps them in place.

Base | Attaching End | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Projection | Dia. | Max. Load Cap., lbs. | Material | Color | Mount Type | Mounting Thread Size | Mounting Hole Thread Type | Mounting Fasteners Included | Mount Type | Mounting Thread Size | Mounting Thread Type | Mounting Fasteners Included | Each | |

| 6" | 5/8" | 20 | Vinyl-Coated Copper | Black | Threaded Hole | 3/8"-24 | UNF | No | Threaded Hole | 3/8"-24 | UNF | No | 00000000 | 000000 |

| 9" | 5/8" | 7 | Vinyl-Coated Copper | Black | Threaded Hole | 3/8"-24 | UNF | No | Threaded Hole | 3/8"-24 | UNF | No | 00000000 | 00000 |

| 12" | 5/8" | 5 | Vinyl-Coated Copper | Black | Threaded Hole | 3/8"-24 | UNF | No | Threaded Hole | 3/8"-24 | UNF | No | 00000000 | 00000 |

| 18" | 5/8" | 3 | Vinyl-Coated Copper | Black | Threaded Hole | 3/8"-24 | UNF | No | Threaded Hole | 3/8"-24 | UNF | No | 00000000 | 00000 |

| 24" | 5/8" | 2.5 | Vinyl-Coated Copper | Black | Threaded Hole | 3/8"-24 | UNF | No | Threaded Hole | 3/8"-24 | UNF | No | 00000000 | 00000 |

| 30" | 5/8" | 2 | Vinyl-Coated Copper | Black | Threaded Hole | 3/8"-24 | UNF | No | Threaded Hole | 3/8"-24 | UNF | No | 00000000 | 00000 |

| 36" | 5/8" | 0.5 | Vinyl-Coated Copper | Black | Threaded Hole | 3/8"-24 | UNF | No | Threaded Hole | 3/8"-24 | UNF | No | 00000000 | 00000 |

Attaching End | Arm Attaching End | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lg. | Rotation Range of Motion | Tilt Range of Motion | Mount Type | Mounting Thread Size | Mounting Thread Type | Max. Load Cap., lbs. | Body Material | Color | Mount Type | Mounting Thread Size | Mounting Thread Type | Features | Each | |

| 2 1/2" | 360° | 90° | Threaded Stud | 1/4"-20 | UNC | 6 | Anodized Aluminum | Black | Threaded Stud | 3/8"-24 | UNF | Locking Knob, Rubber-Padded Camera Seat | 00000000 | 000000 |

Attaching End | Arm Attaching End | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lg. | Rotation Range of Motion | Tilt Range of Motion | Mount Type | Mounting Fasteners Included | Mounting Thread Size | Mounting Thread Type | Max. Load Cap., lbs. | Material | Color | Mount Type | Mounting Thread Size | Mounting Thread Type | Features | Each | |

| 3 7/8" | 360° | 90° | Threaded Hole | Yes | 3/8"-24 | UNF | 6 | Anodized Aluminum | Black | Threaded Stud | 3/8"-24 | UNF | Locking Knob | 00000000 | 000000 |

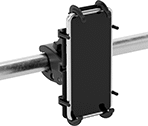

Mobile Device Positioning Arms

Keep smartphones and irregularly-shaped devices, such as radios, in sight and within reach. These arms mount to a variety of surfaces and have 360° range of motion thanks to their ball-and-socket joints. Tilt or rotate them for a better viewing angle and lock the joints in place.

Arms for smartphones have spring-loaded brackets to grip the outside of your smartphone while leaving the screen visible.

Arms for irregularly-shaped devices hold mobile devices that don’t have a uniform shape, such as radios and GPS navigators. They have rubber fingers that adjust to fit around curves, avoid antennas, and grip asymmetrical devices.

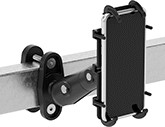

Clamp-on rectangular bar-mount arms have a base that fits around rectangular parts, such as square posts, t-slotted framing, and rails.

Clamp-on pipe-mount arms attach to round bars, pipes, and railings using adjustable jaws. They’re commonly used to mount screens to cart handles.

Magnetic-mount arms cling to magnetic surfaces. They have a strong enough hold to be mounted from any orientation, such as on the side of a machine or overhead on a ceiling.

Suction-mount arms are ideal for mounting devices onto flat surfaces and windows, such as the windshield of your vehicle. The suction cup base is strong enough to keep the arm securely mounted in any orientation.

For technical drawings and 3-D models, click on a part number.

For Device | Projection | Base | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ht. | Wd. | Dp. | Display Ht. | Clamping Range | Min. | Max. | Max. Load Capacity, lbs. | Material | Dia. | Lg. | Wd. | Each | |

Clamp-On Rectangular-Bar Mount | |||||||||||||

| 3 5/8"-7 1/4" | 1 1/4"-3 1/2" | 15/16"-1 1/2" | 0"-5 7/8" | 0"-3" | 5 7/8" | 11 13/16" | 1 | Plastic | __ | 4 3/4" | 1 13/16" | 0000000 | 0000000 |

Clamp-On Pipe Mount | |||||||||||||

| 3 5/8"-7 1/4" | 1 1/4"-3 1/2" | 15/16"-1 1/2" | 0"-4 3/8" | 5/8"-1 1/8" | 8 1/2" | 13 3/4" | 1 | Plastic | __ | 4 3/16" | 1 7/16" | 0000000 | 000000 |

Magnetic Mount | |||||||||||||

| 3 5/8"-7 1/4" | 1 1/4"-3 1/2" | 15/16"-1 1/2" | 0"-1 3/4" | __ | 5 1/8" | 8 1/16" | 1 | Plastic | 2 1/2" | __ | __ | 0000000 | 00000 |

Suction Mount | |||||||||||||

| 3 5/8"-7 1/4" | 1 1/4"-3 1/2" | 15/16"-1 1/2" | 0"-6 5/8" | __ | 6 7/16" | 9 5/16" | 1 | Plastic | 3 5/16" | __ | __ | 0000000 | 00000 |

Tablet Positioning Arms

Position your tablet within view while keeping your hands free to work. These arms mount to a variety of surfaces while keeping a secure grip on your tablet.

Bar-, pipe-, magnetic-, suction-, and threaded-stud-mount arms have ball-and-socket joints that give them a 360° range of motion. Tilt or rotate them for a better viewing angle and lock the joints in place.

Clamp-on rectangular bar-mount arms have a base that fits around rectangular parts, such as square posts, t-slotted framing, and shelving units.

Clamp-on pipe-mount arms attach to round bars, pipes, and railings using adjustable jaws. They’re commonly used to mount screens to cart handles.

Magnetic-mount arms cling to magnetic surfaces and have a strong enough hold to be mounted from any orientation, such as on the side of a machine. They’re good for creating a temporary display because they’re easy to move from place to place.

Suction-mount arms are ideal for mounting tablets onto flat surfaces and windows, such as the windshield of your vehicle. The suction cup base creates a strong hold to keep the arm mounted from any orientation. They’re easy to remove and install, so they’re good for when you want a temporary display.

For technical drawings and 3-D models, click on a part number.