Filter by

Color

ID

OD

Plug Connection Method

For Use With

Fitting Connection

Cap Type

Thread Type

Inside Width

Head Width

DFARS Specialty Metals

Maximum Temperature

Thread Size

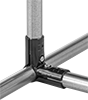

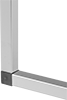

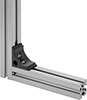

Building and Machinery Hardware

Fluid Handling

Material Handling

Sealing

Electrical

Containers, Storage, and Furniture

Facility and Grounds Maintenance

Heating, Ventilation, and Air Conditioning

Fabricating and Machining

Lubricating

Fastening and Joining

Safety Equipment

Communication