About Composites

More

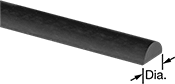

Ultra-Strength Lightweight Carbon Fiber Rods

- Color: Black

- Temperature Range: See table

- Tensile Strength: 120,000-175,000 psi (Excellent)

- Fiber Tensile Stiffness: Standard (33-36 msi)

- Impact Strength: Not Rated

- Hardness: Not Rated

- For Use Outdoors: No

Reinforce structures with these rods—they weigh less than aluminum while remaining strong and almost as rigid. Their fibers are aligned in a single direction, so they hold up to bending across the fibers but will splinter and separate like string cheese when bent along the length of the fiber. Carbon fiber is known for its use in the aerospace industry where a balance of weight and strength is vital.

| Dia. | Dia. Tolerance | Temperature Range | Each | |

12" Lg. | ||||

|---|---|---|---|---|

| 1/16" | -0.006" to 0.006" | -100° F to 180° F | 0000000 | 00000 |

| 3/32" | -0.006" to 0.006" | -100° F to 180° F | 0000000 | 0000 |

| 1/8" | -0.006" to 0.006" | -100° F to 180° F | 0000000 | 0000 |

| 1/4" | -0.006" to 0.006" | -100° F to 180° F | 0000000 | 00000 |

| 5/16" | -0.006" to 0.006" | -100° F to 180° F | 0000000 | 00000 |

| 3/8" | -0.006" to 0.006" | -100° F to 180° F | 0000000 | 00000 |

| 1/2" | -0.006" to 0.006" | -100° F to 180° F | 0000000 | 00000 |

| 5/8" | -0.006" to 0.006" | -100° F to 180° F | 0000000 | 00000 |

| 3/4" | -0.006" to 0.006" | -100° F to 180° F | 0000000 | 000000 |

24" Lg. | ||||

| 1/16" | -0.006" to 0.006" | -100° F to 180° F | 0000000 | 0000 |

| 3/32" | -0.006" to 0.006" | -100° F to 180° F | 0000000 | 00000 |

| 1/8" | -0.006" to 0.006" | -100° F to 180° F | 0000000 | 0000 |

| 1/4" | -0.006" to 0.006" | -100° F to 180° F | 0000000 | 00000 |

| 5/16" | -0.006" to 0.006" | -100° F to 180° F | 0000000 | 00000 |

| 3/8" | -0.006" to 0.006" | -100° F to 180° F | 0000000 | 00000 |

| 1/2" | -0.006" to 0.006" | -100° F to 180° F | 0000000 | 00000 |

| 5/8" | -0.006" to 0.006" | -100° F to 180° F | 0000000 | 000000 |

| 3/4" | -0.006" to 0.006" | -100° F to 180° F | 0000000 | 000000 |

36" Lg. | ||||

| 0.011" | -0.007" to 0.007" | 0° F to 250° F | 0000000 | 00000 |

| 0.039" | -0.007" to 0.007" | 0° F to 250° F | 0000000 | 00000 |

48" Lg. | ||||

| 1/16" | -0.006" to 0.006" | -100° F to 180° F | 0000000 | 00000 |

| 3/32" | -0.006" to 0.006" | -100° F to 180° F | 0000000 | 00000 |

| 1/8" | -0.006" to 0.006" | -100° F to 180° F | 0000000 | 00000 |

| 1/4" | -0.006" to 0.006" | -100° F to 180° F | 0000000 | 00000 |

| 5/16" | -0.006" to 0.006" | -100° F to 180° F | 0000000 | 00000 |

| 3/8" | -0.006" to 0.006" | -100° F to 180° F | 0000000 | 00000 |

| 1/2" | -0.006" to 0.006" | -100° F to 180° F | 0000000 | 000000 |

| 5/8" | -0.006" to 0.006" | -100° F to 180° F | 0000000 | 000000 |

| 3/4" | -0.006" to 0.006" | -100° F to 180° F | 0000000 | 000000 |

Ultra-Strength Lightweight Carbon Fiber Round Tubes

Often used in place of aluminum for structural frames, machinery components, and robotics, these tubes are lighter in weight and almost as rigid. Carbon fiber is known for its use in the aerospace industry where a balance of weight and strength is vital. Thanks to these tubes being lightweight, they reduce wear and stress on motorized parts to extend the life of machinery.

Plain matte tubes have fibers that run in one direction, making them strong in the direction of the fibers. They resist bending across the fibers but will splinter and separate like string cheese when bent along the length of the fiber. Plain glossy tubes and checked tubes have layers with fibers that alternate in two directions, so they resist bending and crushing across the entire tube. They have more structural integrity compared to plain matte tubes.

Checked carbon fiber has the classic carbon-fiber look and is easy to machine—it won’t fray or splinter when cut. Glossy carbon fiber has a shiny finish that can be sanded to matte. Matte carbon fiber is ready to paint and won’t reflect light, making it ideal for photography applications.

- Color: Black

- Max. Temperature: 180° F

- Tensile Strength:

Glossy Tubes: 125,000-175,000 psi (Excellent)

Matte Tubes: 120,000-175,000 psi (Excellent) - Fiber Tensile Stiffness: Standard (33-36 msi)

- Impact Strength: Not Rated

- Hardness: Not Rated

- For Use Outdoors: No

| OD | OD Tolerance | ID | ID Tolerance | Construction Layup | Each | |

12" Lg. | ||||||

|---|---|---|---|---|---|---|

Glossy Tubes (Unidirectional Weave) | ||||||

0.055" Wall Thickness -0.005"; 0.005" | ||||||

| 0.36" | -0.008" to 0.008" | 1/4" | -0.003" to 0.003" | 0°/90° | 00000000 | 000000 |

| 0.485" | -0.008" to 0.008" | 3/8" | -0.003" to 0.003" | 0°/90° | 00000000 | 00000 |

| 0.61" | -0.008" to 0.008" | 1/2" | -0.003" to 0.003" | 0°/90° | 00000000 | 00000 |

| 0.735" | -0.008" to 0.008" | 5/8" | -0.003" to 0.003" | 0°/90° | 00000000 | 00000 |

| 0.86" | -0.008" to 0.008" | 3/4" | -0.003" to 0.003" | 0°/90° | 00000000 | 00000 |

| 1.11" | -0.008" to 0.008" | 1" | -0.003" to 0.003" | 0°/90° | 00000000 | 00000 |

| 1.36" | -0.008" to 0.008" | 1 1/4" | -0.003" to 0.003" | 0°/90° | 00000000 | 00000 |

| 1.61" | -0.01" to 0.01" | 1 1/2" | -0.005" to 0.005" | 0°/90° | 00000000 | 00000 |

| 1.86" | -0.01" to 0.01" | 1 3/4" | -0.005" to 0.005" | 0°/90° | 00000000 | 00000 |

| 2.11" | -0.01" to 0.01" | 2" | -0.005" to 0.005" | 0°/90° | 00000000 | 00000 |

Matte Tubes (Unidirectional Weave) | ||||||

0.01" Wall Thickness | ||||||

| 0.039" | -0.006" to 0.006" | 0.02" | -0.006" to 0.006" | 0° | 00000000 | 00000 |

0.02" Wall Thickness | ||||||

| 0.078" | -0.006" to 0.006" | 0.039" | -0.006" to 0.006" | 0° | 00000000 | 0000 |

| 0.118" | -0.006" to 0.006" | 0.079" | -0.006" to 0.006" | 0° | 00000000 | 0000 |

| 0.236" | -0.006" to 0.006" | 0.196" | -0.006" to 0.006" | 0° | 00000000 | 00000 |

0.04" Wall Thickness | ||||||

| 0.197" | -0.006" to 0.006" | 0.118" | -0.006" to 0.006" | 0° | 00000000 | 00000 |

| 0.314" | -0.006" to 0.006" | 0.236" | -0.006" to 0.006" | 0° | 00000000 | 00000 |

| 0.393" | -0.006" to 0.006" | 0.314" | -0.006" to 0.006" | 0° | 00000000 | 00000 |

0.041" Wall Thickness | ||||||

| 0.472" | -0.006" to 0.006" | 0.39" | -0.006" to 0.006" | 0° | 00000000 | 00000 |

36" Lg. | ||||||

Glossy Tubes (Unidirectional Weave) | ||||||

0.055" Wall Thickness -0.005"; 0.005" | ||||||

| 0.36" | -0.008" to 0.008" | 1/4" | -0.003" to 0.003" | 0°/90° | 00000000 | 00000 |

| 0.485" | -0.008" to 0.008" | 3/8" | -0.003" to 0.003" | 0°/90° | 00000000 | 00000 |

| 0.61" | -0.008" to 0.008" | 1/2" | -0.003" to 0.003" | 0°/90° | 00000000 | 00000 |

| 0.735" | -0.008" to 0.008" | 5/8" | -0.003" to 0.003" | 0°/90° | 00000000 | 00000 |

| 0.86" | -0.008" to 0.008" | 3/4" | -0.003" to 0.003" | 0°/90° | 00000000 | 00000 |

| 1.11" | -0.008" to 0.008" | 1" | -0.003" to 0.003" | 0°/90° | 00000000 | 000000 |

| 1.36" | -0.008" to 0.008" | 1 1/4" | -0.003" to 0.003" | 0°/90° | 00000000 | 000000 |

| 1.61" | -0.01" to 0.01" | 1 1/2" | -0.005" to 0.005" | 0°/90° | 00000000 | 000000 |

| 1.86" | -0.01" to 0.01" | 1 3/4" | -0.005" to 0.005" | 0°/90° | 00000000 | 000000 |

| 2.11" | -0.01" to 0.01" | 2" | -0.005" to 0.005" | 0°/90° | 00000000 | 000000 |

39" Lg. | ||||||

Matte Tubes (Unidirectional Weave) | ||||||

0.01" Wall Thickness | ||||||

| 0.039" | -0.006" to 0.006" | 0.02" | -0.006" to 0.006" | 0° | 00000000 | 00000 |

0.02" Wall Thickness | ||||||

| 0.078" | -0.006" to 0.006" | 0.039" | -0.006" to 0.006" | 0° | 00000000 | 00000 |

| 0.118" | -0.006" to 0.006" | 0.079" | -0.006" to 0.006" | 0° | 0000000 | 00000 |

| 0.236" | -0.006" to 0.006" | 0.196" | -0.006" to 0.006" | 0° | 0000000 | 00000 |

0.04" Wall Thickness | ||||||

| 0.197" | -0.006" to 0.006" | 0.118" | -0.006" to 0.006" | 0° | 0000000 | 00000 |

| 0.314" | -0.006" to 0.006" | 0.236" | -0.006" to 0.006" | 0° | 0000000 | 00000 |

| 0.393" | -0.006" to 0.006" | 0.314" | -0.006" to 0.006" | 0° | 0000000 | 00000 |

0.041" Wall Thickness | ||||||

| 0.472" | -0.006" to 0.006" | 0.39" | -0.006" to 0.006" | 0° | 0000000 | 00000 |

72" Lg. | ||||||

Glossy Tubes (Unidirectional Weave) | ||||||

0.055" Wall Thickness -0.005"; 0.005" | ||||||

| 0.36" | -0.008" to 0.008" | 1/4" | -0.003" to 0.003" | 0°/90° | 00000000 | 00000 |

| 0.485" | -0.008" to 0.008" | 3/8" | -0.003" to 0.003" | 0°/90° | 00000000 | 00000 |

| 0.61" | -0.008" to 0.008" | 1/2" | -0.003" to 0.003" | 0°/90° | 00000000 | 00000 |

| 0.735" | -0.008" to 0.008" | 5/8" | -0.003" to 0.003" | 0°/90° | 00000000 | 00000 |

| 0.86" | -0.008" to 0.008" | 3/4" | -0.003" to 0.003" | 0°/90° | 00000000 | 000000 |

| 1.11" | -0.008" to 0.008" | 1" | -0.003" to 0.003" | 0°/90° | 00000000 | 000000 |

| 1.36" | -0.008" to 0.008" | 1 1/4" | -0.003" to 0.003" | 0°/90° | 00000000 | 000000 |

| 1.61" | -0.01" to 0.01" | 1 1/2" | -0.005" to 0.005" | 0°/90° | 00000000 | 000000 |

| 1.86" | -0.01" to 0.01" | 1 3/4" | -0.005" to 0.005" | 0°/90° | 00000000 | 000000 |

| 2.11" | -0.01" to 0.01" | 2" | -0.005" to 0.005" | 0°/90° | 00000000 | 000000 |

78" Lg. | ||||||

Matte Tubes (Unidirectional Weave) | ||||||

0.01" Wall Thickness | ||||||

| 0.039" | -0.006" to 0.006" | 0.02" | -0.006" to 0.006" | 0° | 00000000 | 00000 |

0.02" Wall Thickness | ||||||

| 0.078" | -0.006" to 0.006" | 0.039" | -0.006" to 0.006" | 0° | 00000000 | 00000 |

| 0.118" | -0.006" to 0.006" | 0.079" | -0.006" to 0.006" | 0° | 00000000 | 00000 |

| 0.236" | -0.006" to 0.006" | 0.196" | -0.006" to 0.006" | 0° | 00000000 | 00000 |

0.04" Wall Thickness | ||||||

| 0.197" | -0.006" to 0.006" | 0.118" | -0.006" to 0.006" | 0° | 00000000 | 00000 |

| 0.314" | -0.006" to 0.006" | 0.236" | -0.006" to 0.006" | 0° | 00000000 | 00000 |

| 0.393" | -0.006" to 0.006" | 0.314" | -0.006" to 0.006" | 0° | 00000000 | 00000 |

0.041" Wall Thickness | ||||||

| 0.472" | -0.006" to 0.006" | 0.39" | -0.006" to 0.006" | 0° | 00000000 | 00000 |

- Color: Black

- Max. Temperature: See table

- Tensile Strength:

Glossy Tubes: 125,000-175,000 psi (Excellent)

Matte Tubes: 120,000-175,000 psi (Excellent) - Fiber Tensile Stiffness: Standard (33-36 msi)

- Impact Strength: Not Rated

- Hardness: Not Rated

- For Use Outdoors: No

| OD | OD Tolerance | ID | ID Tolerance | Max. Temp., °F | Construction Layup | 1 ft. Lg. | 3 ft. Lg. | 6 ft. Lg. | |

Glossy Tubes (Twill Weave) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

0.035" Wall Thickness (-0.005" to 0.005") | |||||||||

| 0.32" | -0.008" to 0.008" | 1/4" | -0.003" to 0.003" | 180° | 0°/90° | 0000000 | |||

| 0.383" | -0.008" to 0.008" | 5/16" | -0.003" to 0.003" | 180° | 0°/90° | 0000000 | |||

| 0.445" | -0.008" to 0.008" | 3/8" | -0.003" to 0.003" | 180° | 0°/90° | 0000000 | |||

| 0.57" | -0.008" to 0.008" | 1/2" | -0.003" to 0.003" | 180° | 0°/90° | 0000000 | |||

| 0.695" | -0.008" to 0.008" | 5/8" | -0.003" to 0.003" | 180° | 0°/90° | 0000000 | |||

| 0.82" | -0.008" to 0.008" | 3/4" | -0.003" to 0.003" | 180° | 0°/90° | 0000000 | |||

| 1.07" | -0.008" to 0.008" | 1" | -0.003" to 0.003" | 180° | 0°/90° | 0000000 | |||

0.064" Wall Thickness (-0.005" to 0.005") | |||||||||

| 0.378" | -0.008" to 0.008" | 1/4" | -0.003" to 0.003" | 180° | 0°/90° | 0000000 | |||

| 0.503" | -0.008" to 0.008" | 3/8" | -0.003" to 0.003" | 180° | 0°/90° | 0000000 | |||

| 0.628" | -0.008" to 0.008" | 1/2" | -0.003" to 0.003" | 180° | 0°/90° | 0000000 | |||

| 0.878" | -0.008" to 0.008" | 3/4" | -0.003" to 0.003" | 180° | 0°/90° | 0000000 | |||

| 1.128" | -0.008" to 0.008" | 1" | -0.003" to 0.003" | 180° | 0°/90° | 0000000 | |||

| 1.378" | -0.008" to 0.008" | 1 1/4" | -0.003" to 0.003" | 180° | 0°/90° | 0000000 | |||

| 1.628" | -0.01" to 0.01" | 1 1/2" | -0.005" to 0.005" | 180° | 0°/90° | 0000000 | |||

| 1.878" | -0.01" to 0.01" | 1 3/4" | -0.005" to 0.005" | 180° | 0°/90° | 0000000 | |||

| 2.128" | -0.01" to 0.01" | 2" | -0.005" to 0.005" | 180° | 0°/90° | 0000000 | |||

| 2.628" | -0.012" to 0.012" | 2 1/2" | -0.005" to 0.005" | 180° | 0°/90° | 0000000 | |||

0.122" Wall Thickness (-0.01" to 0.01") | |||||||||

| 1.244" | -0.012" to 0.012" | 1" | -0.003" to 0.003" | 180° | 0°/90° | 0000000 | |||

| 1.494" | -0.012" to 0.012" | 1 1/4" | -0.003" to 0.003" | 180° | 0°/90° | 0000000 | |||

| 1.744" | -0.014" to 0.014" | 1 1/2" | -0.005" to 0.005" | 180° | 0°/90° | 0000000 | |||

| 1.994" | -0.014" to 0.014" | 1 3/4" | -0.005" to 0.005" | 180° | 0°/90° | 0000000 | |||

| 2.244" | -0.014" to 0.014" | 2" | -0.005" to 0.005" | 180° | 0°/90° | 0000000 | |||

| 2.744" | -0.014" to 0.014" | 2 1/2" | -0.008" to 0.008" | 180° | 0°/90° | 0000000 | |||

| 3.244" | -0.014" to 0.014" | 3" | -0.008" to 0.008" | 180° | 0°/90° | 0000000 | |||

Matte Tubes (Twill Weave) | |||||||||

1/32" Wall Thickness (-0.005" to 0.005") | |||||||||

| 1" | -0.012" to 0.012" | 15/16" | -0.006" to 0.006" | 180° | 0°/90° | 0000000 | |||

0.041" Wall Thickness (-0.005" to 0.005") | |||||||||

| 0.832" | -0.012" to 0.012" | 3/4" | -0.006" to 0.006" | 250° | 0°/90° | 0000000 | |||

0.042" Wall Thickness (-0.005" to 0.005") | |||||||||

| 0.584" | -0.012" to 0.012" | 1/2" | -0.006" to 0.006" | 250° | 0°/90° | 0000000 | |||

| 1.334" | -0.012" to 0.012" | 1 1/4" | -0.006" to 0.006" | 250° | 0°/90° | 0000000 | |||

0.05" Wall Thickness (-0.005" to 0.005") | |||||||||

| 1.6" | -0.012" to 0.012" | 1 1/2" | -0.006" to 0.006" | 250° | 0°/90° | 0000000 | |||

0.06" Wall Thickness (-0.005" to 0.005") | |||||||||

| 1.12" | -0.012" to 0.012" | 1" | -0.006" to 0.006" | 250° | 0°/90° | 0000000 | |||

1/16" Wall Thickness (-0.005" to 0.005") | |||||||||

| 1 5/16" | -0.012" to 0.012" | 1 3/16" | -0.006" to 0.006" | 180° | 0°/90° | 0000000 | |||

| 1 5/8" | -0.012" to 0.012" | 1 1/2" | -0.006" to 0.006" | 180° | 0°/90° | 0000000 | |||

| 1 7/8" | -0.012" to 0.012" | 1 3/4" | -0.006" to 0.006" | 180° | 0°/90° | 0000000 | |||

Ultra-Strength Lightweight Carbon Fiber Half Rounds

- Color: Black

- Temperature Range: 0° F to 250° F

- Tensile Strength: 120,000-175,000 psi (Excellent)

- Fiber Tensile Stiffness: Standard (33-36 msi)

- Impact Strength: Not Rated

- Hardness: Not Rated

- For Use Outdoors: No

Mount these lightweight half rounds on flat surfaces to reinforce frames and structures. Carbon fiber is often used in place of aluminum because it weighs less but is almost as rigid. These half rounds have fibers that run in one direction, making them strongest in the direction of the fibers. They resist bending across the fibers but will splinter and separate like string cheese when bent along the length of the fiber. Carbon fiber is known for its use in the aerospace industry where a balance of weight and strength is critical.

Rigid Ultra-Strength Lightweight Carbon Fiber Round Tubes

- Color: Black

- Temperature Range: -65° F to 180° F

- Tensile Strength: 125,000-175,000 psi (Excellent)

- Fiber Tensile Stiffness: High Modulus (57-63 msi)

- Impact Strength: Not Rated

- Hardness: Not Rated

- For Use Outdoors: No

Often used for structural framing, machinery components, and robotics, these carbon fiber tubes are as stiff as steel yet a fraction of the weight. Carbon fiber is known for its use in the aerospace industry where a balance of weight and strength is vital. Because they are lightweight, they reduce wear and stress on motorized parts, which increases the life of machinery. These tubes are constructed with layers that alternate fibers in two directions, making them difficult to bend.

The checked pattern on these tubes keeps fibers from splintering when the tubes are cut, making them easy to machine. It also has a classic carbon-fiber look. These tubes are glossy and can be sanded for a matte finish.

6 ft. Lg. | ||||||

|---|---|---|---|---|---|---|

| OD | OD Tolerance | ID | ID Tolerance | Construction Layup | Each | |

Checked Glossy Tubes | ||||||

1/16" Wall Thickness (-0.005" to 0.005") | ||||||

| 3/8" | -0.008" to 0.008" | 1/4" | -0.003" to 0.003" | 0°/90° | 0000000 | 0000000 |

| 1/2" | -0.008" to 0.008" | 3/8" | -0.003" to 0.003" | 0°/90° | 0000000 | 000000 |

| 5/8" | -0.008" to 0.008" | 1/2" | -0.003" to 0.003" | 0°/90° | 0000000 | 000000 |

| 3/4" | -0.008" to 0.008" | 5/8" | -0.003" to 0.003" | 0°/90° | 0000000 | 000000 |

| 7/8" | -0.008" to 0.008" | 3/4" | -0.003" to 0.003" | 0°/90° | 0000000 | 000000 |

| 1" | -0.008" to 0.008" | 7/8" | -0.003" to 0.003" | 0°/90° | 0000000 | 000000 |

| 1 1/4" | -0.008" to 0.008" | 1 1/8" | -0.003" to 0.003" | 0°/90° | 0000000 | 000000 |

| 1 1/2" | -0.008" to 0.008" | 1 3/8" | -0.003" to 0.003" | 0°/90° | 0000000 | 000000 |

1/8" Wall Thickness (-0.01" to 0.01") | ||||||

| 1/2" | -0.012" to 0.012" | 1/4" | -0.003" to 0.003" | 0°/90° | 0000000 | 000000 |

| 3/4" | -0.012" to 0.012" | 1/2" | -0.003" to 0.003" | 0°/90° | 0000000 | 000000 |

| 1" | -0.012" to 0.012" | 3/4" | -0.003" to 0.003" | 0°/90° | 0000000 | 000000 |

| 1 1/4" | -0.012" to 0.012" | 1" | -0.003" to 0.003" | 0°/90° | 0000000 | 000000 |

| 1 1/2" | -0.012" to 0.012" | 1 1/4" | -0.003" to 0.003" | 0°/90° | 0000000 | 000000 |

| 1 3/4" | -0.014" to 0.014" | 1 1/2" | -0.005" to 0.005" | 0°/90° | 0000000 | 000000 |

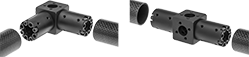

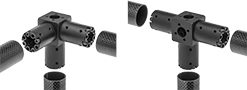

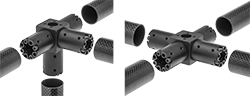

Carbon Fiber Slip-On Framing and Fittings

Stronger than plastic and aluminum, this is the lightest weight framing we offer. It has good resistance to chemicals and salt water. Slip the fittings over rails to construct custom railings, guard rails, storage racks, and shelving. Drill rails and connect fittings with the included hardware.

Connectors come with a universal body and arms that you attach to configure as shown.

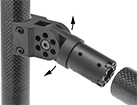

Adjustable-angle wye can be positioned at any angle. Tighten the set screw to secure.

Removable tee allows quick assembly and disassembly of tee connectors at any point along a rail.

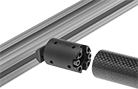

T-slotted framing adapter slides into T-slots to connect carbon fiber framing to T-slotted rails.

| Slip-On Framing Component Shape | For Rail ID | For T-Slot Rail Ht. | Range of Motion | Material | Includes | Each | |

| 90° Elbow, Straight | 1 1/2" | __ | __ | Black Anodized Aluminum | Connecting Hardware | 0000000 | 0000000 |

| Three-Way 90° Elbow, Tee | 1 1/2" | __ | __ | Black Anodized Aluminum | Connecting Hardware | 0000000 | 000000 |

| Four-Way 90° Elbow, Cross | 1 1/2" | __ | __ | Black Anodized Aluminum | Connecting Hardware | 0000000 | 000000 |

| Five-Way 90° Elbow | 1 1/2" | __ | __ | Black Anodized Aluminum | Connecting Hardware | 0000000 | 000000 |

| Adjustable-Angle Wye | 1 1/2" | __ | 180° | Black Anodized Aluminum | Connecting Hardware | 0000000 | 000000 |

| Removable Tee | 1 1/2" | __ | __ | Black Anodized Aluminum | Connecting Hardware | 0000000 | 000000 |

| T-Slotted Framing Adapter | 1 1/2" | 1 1/2" | __ | Black Anodized Aluminum | Connecting Hardware | 0000000 | 00000 |

Panel hanger consists of a connecting ring and a panel bracket to mount panels to rails. Drill rail, align the connecting ring on the inside of the rail with the panel bracket on the outside of the rail, and fasten the two pieces together with included hardware. Mount panels to the end of the bracket with included hardware.

| For Rail ID | For Max. Panel Thick. | Material | Mounting Hole Dia. | Mounting Fasteners Included | Includes | Each | |

| 1 1/2" | 0.075" | Black Anodized Aluminum | 7/32" | No | Connecting Hardware | 0000000 | 000000 |

Rail end attaches to a rail on one end and has a flange on the other end to attach to floors, walls, and ceilings.

Flange | Mouting Holes | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Rail ID | Dia. | Thick. | Bolt Circle Dia. | Material | No. of | Dia. | Mounting Fasteners Included | Includes | Each | |

| 1 1/2" | 3 3/4" | 3/8" | 2 3/4" | Black Anodized Aluminum | 4 | 7/32" | No | Connecting Hardware | 0000000 | 000000 |

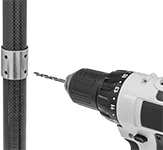

Hole-making jig is a template for aligning and drilling accurate holes in rails. Slide the jig over the rail where holes are necessary, drill the holes, and remove the jig.

| For Rail ID | Drill Bit Size | Includes | Each | |

| 1 1/2" | 7/32" | Drill Bit, Hex Keys, Jig | 0000000 | 000000 |