Filter by

Punch Operation

Manufacturer Model Number

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Measuring Component

Performance

For Flange Hole Diameter

Length Accuracy

Center-Locating Punches for Curved Surfaces

Punch Operation | Angle Measured Range | Graduations | Angle Numeric Increments | For Min. Pipe OD | Material | Punch Material | Includes | Features | Each | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Manual | 0° to 90° | 2.5° | 10° | 1/2" | Aluminum | Steel | Adjustable Dial Protractor | Bubble Level | 000000 | 0000000 | ||

| Spring Loaded | 0° to 90° | 2.5° | 10° | 1" | Aluminum | Steel | Adjustable Dial Protractor | Bubble Level | 000000 | 000000 | ||

Starrett High-Accuracy Combination Square Heads

High-Accuracy Combination Square Heads

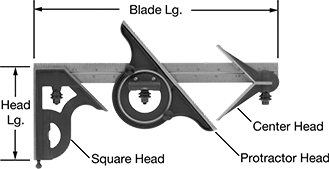

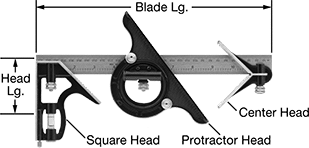

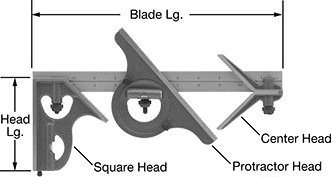

Starrett High-Accuracy Combination Squares

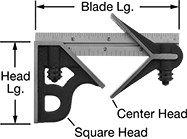

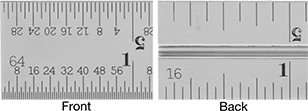

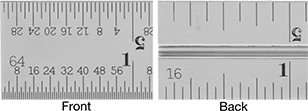

Blades with Square Head and Center Head

|  |

Inch |

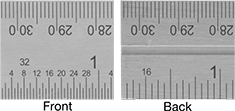

Blade | Graduation | Cast Iron Square Head | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

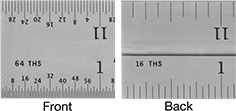

Blade Lg. | Front Graduations (Numeric Graduations) | Back Graduations (Numeric Graduations) | Lg. Accuracy | Wd. | Thk. | Material | Appearance | Color | Color | Type | Head Lg. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Inch | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 1/32" (4/32"), 1/64" (8/64") | 1/8" (1"), 1/16" (1") | -0.002" to 0.004" | 5/8" | 1/16" | Steel | Satin | Chrome, Silver | Black | Etched | 2 1/4" | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

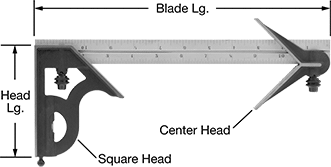

Blades with Square Head with Built-In Level, Center Head, and Scriber

|  |

Inch |

Blade | Graduation | Cast Iron Square Head | Hardened Steel Square Head | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Blade Lg. | Front Graduations (Numeric Graduations) | Back Graduations (Numeric Graduations) | Lg. Accuracy | Wd. | Thk. | Material | Appearance | Color | Color | Type | Head Lg. | Each | Head Lg. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Inch | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 1/32" (4/32"), 1/64" (8/64") | 1/8" (1"), 1/16" (1") | -0.002" to 0.004" | 3/4" | 5/64" | Steel | Satin | Chrome, Silver | Black | Etched | — | ——— | 0 | 2 13/32" | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 1/32" (4/32"), 1/64" (8/64") | 1/8" (1"), 1/16" (1") | -0.0035" to 0.005" | 1" | 3/32" | Steel | Satin | Chrome, Silver | Black | Etched | 4 1/2" | 0000000 | 0000000 | 3 5/8" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

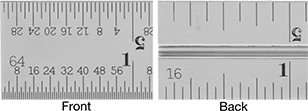

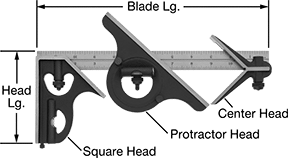

Blades with Square Head with Built-In Level, Center Head, Protractor Head, and Scriber

|  |

Inch |

Blade | Graduation | Cast Iron Square Head | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Blade Lg. | Front Graduations (Numeric Graduations) | Back Graduations (Numeric Graduations) | Lg. Accuracy | Wd. | Thk. | Material | Color | Color | Type | Head Lg. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Inch | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 1/32" (4/32"), 1/64" (8/64") | 1/8" (1"), 1/16" (1") | -0.0035" to 0.005" | 1" | 3/32" | Steel | Silver | Black | Etched | 4 1/2" | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18" | 1/32" (4/32"), 1/64" (8/64") | 1/8" (1"), 1/16" (1") | -0.0035" to 0.006" | 1" | 3/32" | Steel | Silver | Black | Etched | 4 1/2" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 1/32" (4/32"), 1/64" (8/64") | 1/8" (1"), 1/16" (1") | -0.0035" to 0.007" | 1" | 3/32" | Steel | Silver | Black | Etched | 4 1/2" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

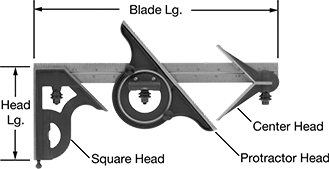

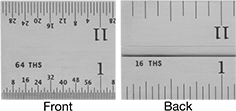

Blades with Square Head with Built-In Level, Center Head, Reversible Protractor Head, and Scriber

|  |

Inch/Metric | |

| |

Inch |

Blade | Graduation | Cast Iron Square Head | Hardened Steel Square Head | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Blade Lg. | Front Graduations (Numeric Graduations) | Back Graduations (Numeric Graduations) | Lg. Accuracy | Wd. | Thk. | Material | Appearance | Color | Color | Type | Head Lg. | Each | Head Lg. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Inch | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 1/32" (4/32"), 1/64" (8/64") | 1/8" (1"), 1/16" (1") | -0.0035" to 0.005" | 1" | 3/32" | Steel | — | Silver | Black | Etched | 4 1/2" | 0000000 | 0000000 | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 1/32" (4/32"), 1/64" (8/64") | 1/8" (1"), 1/16" (1") | -0.0035" to 0.005" | 1" | 3/32" | Steel | Satin | Chrome, Silver | Black | Etched | — | ——— | 0 | 3 5/8" | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 1/32" (4/32"), 1/64" (8/64") | 1/50" (1/10"), 1/100" (1/10") | -0.0035" to 0.005" | 1" | 3/32" | Steel | — | Silver | Black | Etched | 4 1/2" | 0000000 | 000000 | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 1/32" (4/32"), 1/64" (8/64") | 1/50" (1/10"), 1/100" (1/10") | -0.0035" to 0.005" | 1" | 3/32" | Steel | Satin | Chrome, Silver | Black | Etched | — | ——— | 0 | 3 5/8" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18" | 1/32" (4/32"), 1/64" (8/64") | 1/8" (1"), 1/16" (1") | -0.0035" to 0.006" | 1" | 3/32" | Steel | — | Silver | Black | Etched | 4 1/2" | 0000000 | 000000 | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18" | 1/32" (4/32"), 1/64" (8/64") | 1/8" (1"), 1/16" (1") | -0.0035" to 0.006" | 1" | 3/32" | Steel | Satin | Chrome, Silver | Black | Etched | — | ——— | 0 | 3 5/8" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18" | 1/32" (4/32"), 1/64" (8/64") | 1/50" (1/10"), 1/100" (1/10") | -0.0035" to 0.006" | 1" | 3/32" | Steel | Satin | Chrome, Silver | Black | Etched | — | ——— | 0 | 3 5/8" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 1/32" (4/32"), 1/64" (8/64") | 1/8" (1"), 1/16" (1") | -0.0035" to 0.007" | 1" | 3/32" | Steel | — | Silver | Black | Etched | 4 1/2" | 0000000 | 000000 | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 1/32" (4/32"), 1/64" (8/64") | 1/8" (1"), 1/16" (1") | -0.0035" to 0.007" | 1" | 3/32" | Steel | Satin | Chrome, Silver | Black | Etched | — | ——— | 0 | 3 5/8" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 1/32" (4/32"), 1/64" (8/64") | 1/50" (1/10"), 1/100" (1/10") | -0.0035" to 0.007" | 1" | 3/32" | Steel | Satin | Chrome, Silver | Black | Etched | — | ——— | 0 | 3 5/8" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Inch/Metric | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 11 3/4"/300 mm | 0.5 mm (10 mm), 1/32" (4/32") | 1 mm (10 mm), 1/64" (8/64") | -0.0035" to 0.005"/ -0.09 mm to 0.15 mm | 1" | 3/32" | Steel | — | Silver | Black | Etched | 4 1/2" | 0000000 | 000000 | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 11 3/4"/300 mm | 0.5 mm (10 mm), 1/32" (4/32") | 1 mm (10 mm), 1/64" (8/64") | -0.0035" to 0.005"/ -0.09 mm to 0.15 mm | 1" | 3/32" | Steel | Satin | Chrome, Silver | Black | Etched | — | ——— | 0 | 3 5/8" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 23 1/2"/600 mm | 0.5 mm (10 mm), 1/32" (4/32") | 1 mm (10 mm), 1/64" (8/64") | -0.0035" to 0.007"/ -0.11 mm to 0.25 mm | 1" | 3/32" | Steel | — | Silver | Black | Etched | 4 1/2" | 0000000 | 000000 | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

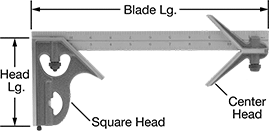

Combination Squares

Blades with Square Head with Built-In Level, Center Head, Reversible Protractor Head with Built-In Level, and Scriber

|  |

Inch/Metric |

Blade | Graduation | Aluminum Square Head | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Blade Lg. | Front Graduations (Numeric Graduations) | Back Graduations (Numeric Graduations) | Wd. | Thk. | Material | Color | Color | Type | Head Lg. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Inch/Metric | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12"/300 mm | 1 mm (10 mm), 1/32" (4/32") | 1 mm (10 mm), 1/16" (1") | 1" | 3/32" | Steel | Silver | Black | Etched | 4 1/4" | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

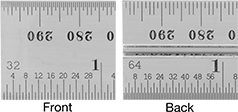

High-Accuracy Combination Squares

Blades with Square Head with Built-In Level, Center Head, and Scriber

|  |

Inch |

Blade | Graduation | Cast Iron Square Head | Hardened Cast Iron Square Head | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Blade Lg. | Front Graduations (Numeric Graduations) | Back Graduations (Numeric Graduations) | Lg. Accuracy | Wd. | Thk. | Material | Appearance | Color | Color | Type | Head Lg. | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Inch | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 1/32" (4/32"), 1/64" (8/64") | 1/8" (1"), 1/16" (1") | -0.0025" to 0.0025" | 1" | 3/32" | Steel | Satin | Chrome, Silver | Black | Etched | 4 1/2" | 00000000 | 0000000 | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Blades with Square Head with Built-In Level, Center Head, Reversible Protractor Head, and Scriber

|  |

Inch |

Blade | Graduation | Cast Iron Square Head | Hardened Cast Iron Square Head | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Blade Lg. | Front Graduations (Numeric Graduations) | Back Graduations (Numeric Graduations) | Lg. Accuracy | Wd. | Thk. | Material | Appearance | Color | Color | Type | Head Lg. | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Inch | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 1/32" (4/32"), 1/64" (8/64") | 1/8" (1"), 1/16" (1") | -0.0025" to 0.0025" | 1" | 3/32" | Steel | Satin | Chrome, Silver | Black | Etched | 4 1/2" | 00000000 | 0000000 | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

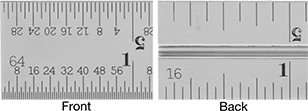

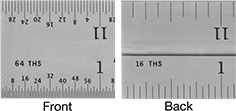

Scratch-Resistant High-Accuracy Combination Squares

Blades with Square Head with Built-In Level, Center Head, Protractor Head, and Scriber

|  |

Inch |

Blade | Graduation | Cast Iron Square Head | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Blade Lg. | Front Graduations (Numeric Graduations) | Back Graduations (Numeric Graduations) | Lg. Accuracy | Wd. | Thk. | Material | Color | Color | Type | Head Lg. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Inch | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 1/32" (4/32"), 1/64" (8/64") | 1/8" (1"), 1/16" (1") | -0.002" to 0.002" | 1" | 3/32" | Titanium-Coated Steel | Gold | Black | Etched | 4 1/2" | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Magnetic Pipe Flange Aligners with Level

For Flange Hole Dia. | For Max. Flange Hole Ctr.-to-Ctr. Distance | Level Lg. | Aligner Connection Method | Includes | Cone Material | Magnet Material | Container Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Aluminum Body | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" to 2" | 9 1/2" | 10 1/2" | Magnetic | Threaded Cones | Steel | Neodymium | Carrying Case | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pipe Flange Aligners with Protractor

|

For Flange Hole Dia. | Angle Measured Range | Graduations (Angle Increments) | For Distance Between Bolt Holes | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" to 1 3/4" | 0° to 90° | 2.5° (2°) | 2" to 5 1/2" | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pipe Flange Aligner Pins with Horizontal Level

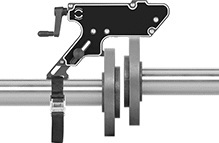

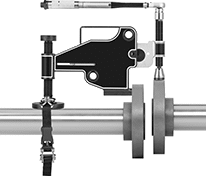

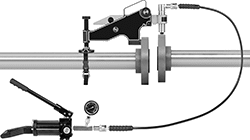

Pipe Flange Alignment Kits

Alignment Mechanism | Wt. Cap., lb. | For Min. Flange Hole Dia. | Includes | Container Type | Each | ||

|---|---|---|---|---|---|---|---|

| Hand Crank | 2,400 | 5/8" | Strap | — | 0000000 | 000000000 | |

| Ratchet | 9,900 | 1" | Socket, Strap, Wrench | Plastic Carrying Case | 0000000 | 00000000 | |

| Hydraulic | 22,200 | 1 3/8" | Hand Pump with Gauge, Hydraulic Cylinder, Hydraulic Hose, Strap | Plastic Carrying Case | 0000000 | 00000000 |

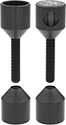

Stepped Pipe Flange Aligner Pins

Pipe Flange Aligner Pins

Magnetic Pipe Flange Aligner Pins

Pipe Flange Aligners | Pipe Flange Aligner Extensions | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Flange | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hole Dia. | Thk. | Aligner Connection Method | Magnet Material | Pair | Lg. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" to 7/8" | 7/8" | Magnetic | Neodymium | 0000000 | 000000 | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" to 1 7/16" | 1 3/8" | Magnetic | Neodymium | 0000000 | 000000 | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" to 1 15/16" | 2 3/4" | Magnetic | Neodymium | 0000000 | 000000 | 1 3/4" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||