About Plastic

More

About Sealant Flexibility

More

Wear-, Impact-, and Chemical-Resistant PTFE Rods

- Color: See table

- Temperature Range: -400° to 550° F

- Tensile Strength: 2,000-3,100 psi (Poor)

- Impact Strength: 6 ft.-lbs./in. (Excellent)

- Hardness: Not Rated (Medium)

- For Use Outdoors: No

- Specifications Met: See table

PTFE is modified with a filler material to create these impact-resistant rods. They have a super-slippery surface that resist wear, as well as excellent resistance to chemicals and extreme temperatures. These easy-to-machine rods are nonabsorbent, so they won’t swell when exposed to water. They’re also good electrical insulators.

Grade LR is often used for sleeve, flange, and linear bearings.

1 ft. Lg. | ||||

|---|---|---|---|---|

| Dia. | Dia. Tolerance | Color | Each | |

Rulon LR | ||||

| 1/4" | 0" to 0.065" | Maroon | 0000000 | 000000 |

| 3/8" | 0" to 0.065" | Maroon | 0000000 | 00000 |

| 1/2" | 0" to 0.065" | Maroon | 0000000 | 00000 |

| 5/8" | 0" to 0.065" | Maroon | 0000000 | 000000 |

| 3/4" | 0" to 0.065" | Maroon | 0000000 | 000000 |

| 7/8" | 0" to 0.065" | Maroon | 0000000 | 000000 |

| 1" | 0" to 0.065" | Maroon | 0000000 | 000000 |

| 1 1/2" | 0" to 0.065" | Maroon | 0000000 | 000000 |

Wear-, Impact-, and Chemical-Resistant PTFE Sheets

These sheets are manufactured from Rulon PTFE, a PTFE that’s been modified with a filler material. In addition to having the superior chemical and temperature resistance of PTFE, they have excellent impact resistance and a super-slippery surface that resists wear. These easy-to-machine sheets are nonabsorbent, so they won’t swell when exposed to water. They’re also good electrical insulators.

Grade LR is often used for sleeve, flange, and linear bearings.

- Color: Maroon

- Temperature Range: -400° to 550° F

- Tensile Strength: 2,000-3,100 psi (Poor)

- Impact Strength: 6 ft.-lbs./in. (Excellent)

- Hardness: Not Rated (Medium)

- For Use Outdoors: No

Machinable Ceramic-Filled Wear- and Chemical-Resistant PEEK

- Color: White

- Temperature Range: -100° to 500° F

- Tensile Strength: 14,100 psi (Excellent)

- Impact Strength: 0.66 ft.-lbs./in. (Poor)

- For Use Outdoors: No

These PEEK sheets can be machined to tight tolerances for use in electrical and semiconductor parts, such as test sockets. With a ceramic filler, they have excellent hardness and rigidity. The filler also acts as an effective barrier against gas and fluid permeation. These sheets maintain their shape when exposed to temperature changes. They also withstand wear from abrasion and repetitive processes.

Caulking Tape

Press this adhesive-backed plastic tape into place for an immediate light-duty seal. It has a score line for easy installation in a corner.

| Wd. | Thick. | Lg., ft. | Reaches Full Strength | Tensile Strength | Hardness | Temp. Range, °F | For Joining | Color | Each | |

PET Plastic with Butyl Rubber Adhesive | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 7/8" | 1/4" | 11 | 12 hrs. | Not Rated | Not Rated | 55° to 80° | Metal, Plastic, Rubber, Composites, Glass, Masonry, Wood | White | 0000000 | 00000 |

Ultra High- and Low-Temperature Rope Edge Seals

A wide temperature range makes these ceramic seals equally suitable for use in cryogenic applications as they are for extreme-heat applications. They’re made from tightly woven calcium alumina silicate, so they won’t burn and they resist molten metal splash. They also resist steam, salts, grease, detergents, bleach, and hydraulic fluid; however, they will absorb these substances. Push them into the groove that’s commonly built into oven doors, furnaces, and tanks.

| Wd. | Temp. Range, °F | For Use Outdoors | Specifications Met | Color | 5 ft. | 10 ft. | 25 ft. | |

Ceramic Fiber—Plain Back | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/8" | -300° to 1100° | No | MIL-I-24244 | White | 0000000 | |||

| 1/4" | -300° to 1100° | No | MIL-I-24244 | White | 0000000 | |||

| 3/8" | -300° to 1100° | No | MIL-I-24244 | White | 0000000 | |||

| 1/2" | -300° to 1100° | No | MIL-I-24244 | White | 0000000 | |||

| 3/4" | -300° to 1100° | No | MIL-I-24244 | White | 0000000 | |||

| 1" | -300° to 1100° | No | MIL-I-24244 | White | 0000000 | |||

Ultra High- and Low-Temperature Ultra-Conformable Rope Edge Seals

Alumina silicate is loosely woven to create these ceramic seals that are stronger, more flexible, and able to resist higher temperatures than Ultra High- and Low-Temperature Rope Edge Seals. They are commonly used as to tie products together during high-temperature processing, but they can handle cryogenic applications just as well. They won’t burn and they resist molten metal splash. These seals also resist steam, salts, grease, detergents, bleach, and hydraulic fluid; however, they will absorb these substances. Push them into the groove that’s commonly built into oven doors, furnaces, and tanks.

| Wd. | Temp. Range, °F | For Use Outdoors | Specifications Met | Color | 5 ft. | 10 ft. | 25 ft. | |

Ceramic Fiber—Plain Back | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/4" | -300° to 2300° | No | MIL-I-24244 | White | 0000000 | |||

| 3/8" | -300° to 2300° | No | MIL-I-24244 | White | 0000000 | |||

| 1/2" | -300° to 2300° | No | MIL-I-24244 | White | 0000000 | |||

| 3/4" | -300° to 2300° | No | MIL-I-24244 | White | 0000000 | |||

| 1" | -300° to 2300° | No | MIL-I-24244 | White | 0000000 | |||

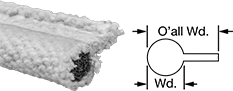

Ultra High-Temperature Chemical-Resistant Flange-Mount Rope Edge Seals

A ceramic cover makes these seals more chemical resistant than the seals with a silica cover. Seals resist acids (except hydrofluoric and phosphoric), diluted alkalies, most refrigerants, salts, and grease. The flange on these seals slides into a slot that is commonly found on oven, furnace, and boiler doors; it can be positioned to cover large gaps.

| O'all Wd. | Wd. | Flange Thick. | Core Material | Max. Temp., °F | For Use Outdoors | Color | 1 ft. | 10 ft. | 25 ft. | |

Ceramic Fabric—Plain Back | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 7/8" | 3/8" | 3/16" | Inconel 625 Nickel | 1700° | No | White | 0000000 | |||

| 1" | 1/2" | 3/16" | Inconel 625 Nickel | 1700° | No | White | 0000000 | |||

| 1 3/4" | 3/4" | 3/16" | Inconel 625 Nickel | 1700° | No | White | 0000000 | |||

| 2" | 1/2" | 3/16" | Inconel 625 Nickel | 1700° | No | White | 0000000 | |||

| 2" | 1" | 3/16" | Inconel 625 Nickel | 1700° | No | White | 0000000 | |||

| 3" | 1" | 3/16" | Inconel 625 Nickel | 1700° | No | White | 0000000 | |||