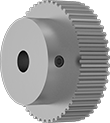

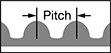

XL Series Corrosion-Resistant Timing Belt Pulleys

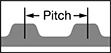

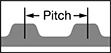

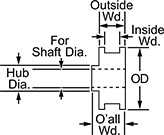

Pulleys are anodized aluminum, which is more corrosion resistant than steel. They are XL series (extra light) and have trapezoidal teeth. Select a pulley with a maximum belt width that’s the same or larger than your timing belt width.

For tight spots, choose a pulley without a hub.

For technical drawings and 3-D models, click on a part number.

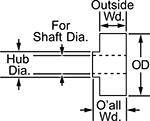

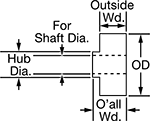

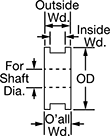

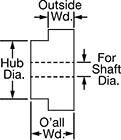

| OD | Number of Teeth | Pitch | For Shaft Dia. | Bore Type | Inside Wd. | Outside Wd. | Overall Wd. | Pitch Dia. | Fabrication | Material | Hub Dia. | Each | |

For 3/8" Max. Belt Wd. | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

With Hub—Two Flanges | |||||||||||||

| 1.75" | 24 | 0.200" | 3/8" | Finished | 0.43" | 0.563" | 0.906" | 1.528" | Machined | Anodized Aluminum | 1.063" | 0000000 | 000000 |

With Hub | |||||||||||||

| 2.845" | 45 | 0.200" | 3/8" | Finished | __ | 0.563" | 1" | 2.865" | Machined | Anodized Aluminum | 1.5" | 0000000 | 00000 |

| 3.163" | 50 | 0.200" | 3/8" | Finished | __ | 0.563" | 1" | 3.183" | Machined | Anodized Aluminum | 1.5" | 0000000 | 00000 |

| 3.8" | 60 | 0.200" | 3/8" | Finished | __ | 0.563" | 1" | 3.82" | Machined | Anodized Aluminum | 1.5" | 0000000 | 00000 |

Without Hub—Two Flanges | |||||||||||||

| 1.25" | 16 | 0.200" | 3/8" | Finished | 0.429" | 0.563" | 0.563" | 1.019" | Machined | Anodized Aluminum | __ | 00000000 | 00000 |

| 1.312" | 18 | 0.200" | 3/8" | Finished | 0.429" | 0.563" | 0.563" | 1.146" | Machined | Anodized Aluminum | __ | 00000000 | 00000 |

| 1.5" | 20 | 0.200" | 3/8" | Finished | 0.429" | 0.563" | 0.563" | 1.273" | Machined | Anodized Aluminum | __ | 00000000 | 00000 |

| 1.625" | 22 | 0.200" | 3/8" | Finished | 0.429" | 0.563" | 0.563" | 1.401" | Machined | Anodized Aluminum | __ | 00000000 | 00000 |

| 1.75" | 24 | 0.200" | 3/8" | Finished | 0.429" | 0.563" | 0.563" | 1.528" | Machined | Anodized Aluminum | __ | 00000000 | 00000 |

| 2.125" | 30 | 0.200" | 3/8" | Finished | 0.429" | 0.563" | 0.563" | 1.91" | Machined | Anodized Aluminum | __ | 00000000 | 00000 |

| 2.25" | 32 | 0.200" | 3/8" | Finished | 0.429" | 0.563" | 0.563" | 2.037" | Machined | Anodized Aluminum | __ | 00000000 | 00000 |

XL Series Timing Belt Pulleys

Pulleys are XL series (extra light) and have trapezoidal teeth. Select a pulley with a maximum belt width that’s the same or larger than your timing belt width.

For technical drawings and 3-D models, click on a part number.

| OD | Number of Teeth | Pitch | For Shaft Dia. | Bore Type | Inside Wd. | Outside Wd. | Overall Wd. | Pitch Dia. | Number of Flanges | Fabrication | Hub Dia. | Each | |

For 3/8" Max. Belt Wd. | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1.188" | 15 | 0.200" | 3/8" | Finished | 0.43" | 0.563" | 0.812" | 0.955" | 2 | Machined | 0.75" | 00000000 | 000000 |

| 1.25" | 16 | 0.200" | 3/8" | Finished | 0.43" | 0.563" | 0.812" | 1.019" | 2 | Machined | 0.688" | 00000000 | 00000 |

| 1.375" | 18 | 0.200" | 3/8" | Finished | 0.43" | 0.563" | 0.812" | 1.146" | 2 | Machined | 0.812" | 00000000 | 00000 |

| 1.625" | 22 | 0.200" | 3/8" | Finished | 0.43" | 0.563" | 0.875" | 1.401" | 2 | Machined | 1" | 00000000 | 00000 |

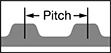

L Series Timing Belt Pulleys

Pulleys are L series (light) and have trapezoidal teeth. Select a pulley with a maximum belt width that’s the same or larger than your timing belt width.

For technical drawings and 3-D models, click on a part number.

| OD | For Shaft Dia. | Number of Teeth | Pitch | Bore Type | Inside Wd. | Outside Wd. | Overall Wd. | Pitch Dia. | Number of Flanges | Fabrication | Material | Hub Dia. | Each | |

For 1/2" Max. Belt Wd. | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1.438" | 3/8" | 10 | 0.375" | Finished | 0.563" | 0.75" | 1.125" | 1.194" | 2 | Sintered | Steel | 0.813" | 0000000 | 000000 |

| 1.672" | 3/8" | 12 | 0.375" | Finished | 0.563" | 0.75" | 1.25" | 1.432" | 2 | Sintered | Steel | 1.063" | 0000000 | 00000 |

| 1.922" | 3/8" | 14 | 0.375" | Finished | 0.563" | 0.75" | 1.25" | 1.671" | 2 | Sintered | Steel | 1.125" | 0000000 | 00000 |

For 3/4" Max. Belt Wd. | ||||||||||||||

| 1.672" | 3/8" | 12 | 0.375" | Finished | 0.813" | 1" | 1.5" | 1.432" | 2 | Sintered | Steel | 1.063" | 00000000 | 00000 |

| 1.922" | 3/8" | 14 | 0.375" | Finished | 0.813" | 1" | 1.5" | 1.671" | 2 | Sintered | Steel | 1.125" | 00000000 | 00000 |

For 1" Max. Belt Wd. | ||||||||||||||

| 1.922" | 3/8" | 14 | 0.375" | Finished | 1.063" | 1.25" | 1.75" | 1.671" | 2 | Sintered | Steel | 1.125" | 00000000 | 00000 |

High-Strength GT Timing Belt Pulleys

For higher speed or higher torque applications, these GT series timing belt pulleys provide a more precise fit than HTD pulleys. Use them where accuracy is critical, such as in storage and retrieval systems or in robotics. Similar to HTD timing belt pulleys, their teeth are curved for high strength. The curved teeth create positive grip engagement with timing belts, so these pulleys do not require re-tensioning—unlike drives using V-belts or sheaves. And unlike chain drives, there’s no metal-on-metal contact, so these pulleys don’t require lubrication.

Anodized aluminum pulleys are lightweight and resist corrosion. They have a finished bore and come with set screws for mounting on shafts.

For technical drawings and 3-D models, click on a part number.

| Number of Teeth | Pitch, mm | For Shaft Diameter | Bore Type | Outside Width, mm | Overall Width, mm | Pitch Diameter, mm | Fabrication | Material | Hub Diameter, mm | Each | |

For 6 mm Maximum Belt Width | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 120 | 2 | 3/8" | Finished | 9.65 | 19.05 | 76.403 | Machined | Anodized Aluminum | 38.1 | 00000000 | 000000 |

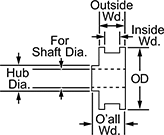

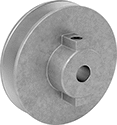

V-Belt Pulleys

Pulleys for 2L and 3L belt are for fractional-horsepower V-belt drives.

For technical drawings and 3-D models, click on a part number.

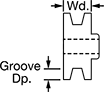

| OD | For Shaft Dia. | Pitch Dia. | Wd. | O'all Wd. | Groove Dp. | Material | Body Type | Includes | Each | |

For 3L Belts | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1" | 3/8" | 0.9" | 1/2" | 7/8" | 0.25" | Zinc | Solid | One Set Screw | 00000000 | 00000 |

| 2" | 3/8" | 1.9" | 1/2" | 1" | 0.375" | Zinc | Solid | One Set Screw | 00000000 | 0000 |

| 2.5" | 3/8" | 2.4" | 1/2" | 1" | 0.375" | Zinc | Solid | One Set Screw | 00000000 | 00000 |

| 3" | 3/8" | 2.9" | 1/2" | 1" | 0.375" | Zinc | Solid | One Set Screw | 00000000 | 00000 |

| 3.5" | 3/8" | 3.4" | 1/2" | 1" | 0.375" | Zinc | Solid | One Set Screw | 00000000 | 00000 |

| 4" | 3/8" | 3.9" | 1/2" | 1" | 0.375" | Zinc | Solid | One Set Screw | 00000000 | 00000 |

For 4L, A Belts | ||||||||||

| 1.5" | 3/8" | 1.25" | 21/32" | 1 5/32" | 0.5" | Zinc | Solid | One Set Screw | 00000000 | 0000 |

| 1.75" | 3/8" | 1.5" | 21/32" | 1 13/64" | 0.5" | Zinc | Solid | One Set Screw | 00000000 | 0000 |

| 2" | 3/8" | 1.75" | 41/64" | 1 1/16" | 0.5" | Zinc | Solid | One Set Screw | 00000000 | 0000 |

| 2.25" | 3/8" | 2" | 41/64" | 1 3/16" | 0.5" | Zinc | Solid | One Set Screw | 00000000 | 0000 |

| 2.5" | 3/8" | 2.25" | 41/64" | 1 3/16" | 0.5" | Zinc | Solid | One Set Screw | 00000000 | 0000 |

| 2.75" | 3/8" | 2.5" | 41/64" | 1 3/16" | 0.5" | Zinc | Solid | One Set Screw | 00000000 | 0000 |

V-Belt Idler Pulleys

These pulleys spin freely on built-in ball bearings to maintain tension for reduced wear and vibration. Commonly used with belt tensioners (sold separately), they are lightweight and corrosion and abrasion resistant. Bearings are double sealed to keep dirt out.

For technical drawings and 3-D models, click on a part number.

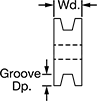

| No. of Grooves | OD | For Shaft Dia. | Pitch Dia. | Wd. | Groove Dp. | Material | Body Type | Each | |

For 4L, A, AX Belts | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1 | 3" | 3/8" | 2" | 45/64" | 0.5" | Nylon Plastic | Solid | 0000000 | 000000 |

| 1 | 4" | 3/8" | 2.99" | 45/64" | 0.5" | Nylon Plastic | Solid | 0000000 | 00000 |

For 5L, B, BX Belts | |||||||||

| 1 | 3.1" | 3/8" | 1.84" | 25/32" | 0.63" | Nylon Plastic | Solid | 0000000 | 00000 |

| 1 | 4" | 3/8" | 2.84" | 55/64" | 0.58" | Nylon Plastic | Solid | 0000000 | 00000 |

| 1 | 5" | 3/8" | 3.84" | 51/64" | 0.6" | Nylon Plastic | Solid | 0000000 | 00000 |

Round-Belt Idler Pulleys

These pulleys spin freely on built-in bearings to maintain tension for reduced wear and vibration. They are often used with belt tensioners (sold separately). Ball bearings are double sealed to keep dirt out.

Brass pulleys are nonsparking and fit in extremely small spaces. Nylon pulleys are lightweight and corrosion and abrasion resistant.

For technical drawings and 3-D models, click on a part number.

| For Belt Dia. | OD | For Shaft Dia. | Dia. | Wd. | Groove Dp. | Material | Bearing Material | Each | |

| 3/16" | 2" | 3/8" | 1.81" | 9/32" | 0.095" | Brass | Stainless Steel | 000000 | 000000 |

| 3/16" | 2.5" | 3/8" | 2.31" | 9/32" | 0.095" | Brass | Stainless Steel | 0000000 | 00000 |

| 1/4" | 4.5" | 3/8" | 3.74" | 55/64" | 0.36" | Nylon Plastic | Steel | 00000000 | 00000 |

| 1/4" | 6" | 3/8" | 5.2" | 51/64" | 0.4" | Nylon Plastic | Steel | 00000000 | 00000 |

| 3/8" | 3.1" | 3/8" | 2.45" | 39/64" | 0.3" | Nylon Plastic | Steel | 00000000 | 00000 |

| 3/8" | 3.5" | 3/8" | 2.75" | 49/64" | 3/8" | Nylon Plastic | Steel | 00000000 | 00000 |

| 3/8" | 5.5" | 3/8" | 4.62" | 9/16" | 0.44" | Nylon Plastic | Steel | 00000000 | 00000 |

| 11/16" | 4.8" | 3/8" | 4" | 1 1/16" | 0.41" | Nylon Plastic | Steel | 00000000 | 00000 |

Flat-Belt Idler Pulleys

These pulleys spin freely on built-in bearings to maintain tension for reduced wear and vibration. They’re often used with belt tensioners (sold separately).

Nylon pulleys are lightweight and corrosion resistant.

Pulleys with ball bearings ensure proper positioning inside a tube or housing. They’re sealed to block out dust and contaminants better than pulleys with needle roller bearings.

For technical drawings and 3-D models, click on a part number.

| For Belt Wd. | OD | For Shaft Dia. | Dia. | Wd. | Groove Dp. | Material | Each | |

With Ball Bearings | ||||||||

|---|---|---|---|---|---|---|---|---|

| 5/8" | 3 1/2" | 3/8" | 3" | 1 3/32" | 0.25" | Nylon Plastic | 0000000 | 000000 |

| 13/16" | 2.8" | 3/8" | 2 33/64" | 1 7/32" | 0.11" | Nylon Plastic | 0000000 | 00000 |

| 13/16" | 3 1/2" | 3/8" | 3" | 1 7/32" | 0.25" | Nylon Plastic | 0000000 | 00000 |

| 7/8" | 2.4" | 3/8" | 2" | 1 5/32" | 0.18" | Nylon Plastic | 0000000 | 00000 |

| 7/8" | 3" | 3/8" | 2 1/2" | 1 5/16" | 0.25" | Nylon Plastic | 0000000 | 00000 |

| 7/8" | 5.6" | 3/8" | 5 1/32" | 1 19/64" | 0.26" | Nylon Plastic | 0000000 | 00000 |

| 29/32" | 4 1/2" | 3/8" | 4" | 1 25/64" | 0.25" | Nylon Plastic | 0000000 | 00000 |

| 1 1/8" | 2.1" | 3/8" | 1 7/8" | 1 35/64" | 0.09" | Nylon Plastic | 0000000 | 00000 |

| 1 1/8" | 3.4" | 3/8" | 2 31/32" | 1 43/64" | 0.2" | Nylon Plastic | 0000000 | 00000 |