About Roller Chain and Sprockets

More

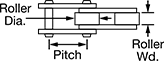

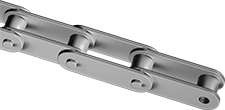

Flat-Edge ANSI Roller Chain and Links

The flat, oblong side plates on this chain make it ideal for conveying items in manufacturing and packaging lines.

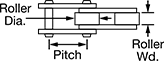

Double-pitch chain has links that are twice as long as single-pitch chain links. It’s good for long drives and is lightweight. However, it operates at slower speeds than single-pitch chain. Use it with standard sprockets with at least 24 teeth.

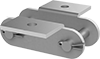

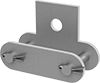

Connecting links are also known as master links. They're used to join the ends of a chain length. The side plate is easy to remove for attaching to a chain. Adding links are also known as roller links. They require two connecting links to join chain. Adding-and-connecting links are also known as half links and offset links. A combination of connecting and adding links, they can join chain that requires an odd number of links.

Chain |  Connecting Link |  Adding Link |

Adding-and-Connecting Link |  |

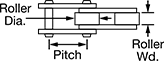

Corrosion-Resistant Flat-Edge ANSI Roller Chain and Links

Chain |  Connecting Link |  Adding Link |

Adding-and-Connecting Link |  |

Made of stainless steel, this chain has excellent corrosion resistance. The flat edges of this chain create a level surface, so items riding on manufacturing and packaging lines won’t get caught in divots the way they do on standard roller chain. Designed for long drives and low- to moderate-speed applications, its links are twice as long as those found on other roller chain. Use with standard sprockets with at least 24 teeth.

Connecting links are also known as master links. They're used to join the ends of a chain length. The side plate is easy to remove for attaching to a chain. Adding links are also known as roller links. They require two connecting links to join chain. Adding-and-connecting links are also known as half links and offset links. A combination of connecting and adding links, they can join chain that requires an odd number of links. The side plate is easy to remove for attaching to chain.

High-Strength Corrosion-Resistant Flat-Edge ANSI Roller Chain and Links

Chain |  Connecting Link |  Adding Link |

Adding-and-Connecting Link |  |

This treated steel chain has over six times the capacity of stainless steel chain. The flat edges of this chain create a level surface, so items riding on manufacturing and packaging lines won’t get caught in divots the way they do on standard roller chain. The links are also twice as long as standard roller chain, so they’re best for long drives and low- to moderate-speed applications. Use with standard sprockets with at least 24 teeth.

Connecting links are also known as master links. They're used to join the ends of a chain length. The side plate is easy to remove for attaching to a chain. Adding links are also known as roller links. They require two connecting links to join chain. Adding-and-connecting links are also known as half links and offset links. A combination of connecting and adding links, they can join chain that requires an odd number of links. The side plate is easy to remove for attaching to chain.

Flat-Edge ANSI Roller Chain Attachment Links

Flat, oblong side plates make these links ideal for use with flat-edge ANSI roller chain. Add them to your roller chain to attach brackets or guides, or to move materials directly. Use them for conveying, timing, and aligning.

Connecting links are also known as master links. They're used to join the ends of a chain length. The side plate is easy to remove for attaching to a chain.

Adding links are also known as roller links. They require two connecting links to join chain.

| Roller Chain Trade No. | Working Load, lbs. | Tab Lg. | Mount. Hole Dia. | Each | |

A-1 | |||||

|---|---|---|---|---|---|

Tab Connecting Links—Steel | |||||

| C2040 | 600 | 0.465" | 0.141" | 0000000 | 00000 |

K-1 | |||||

Tab Connecting Links—Steel | |||||

| C2040 | 600 | 0.465" | 0.141" | 0000000 | 0000 |

Tab Adding Links—Steel | |||||

| C2040 | 600 | 0.469" | 9/64" | 0000000 | 0000 |

SA-1 | |||||

Tab Connecting Links—Steel | |||||

| C2040 | 600 | 0.555" | 0.203" | 0000000 | 0000 |

SK-1 | |||||

Tab Connecting Links—Steel | |||||

| C2040 | 600 | 0.555" | 0.203" | 0000000 | 0000 |