About Backflow-Prevention Valves

More

Heavy Duty Check Valves with Push-to-Connect Fittings for Drinking Water

A metal body provides more durability than plastic. Insert tubing into the push-to-connect fittings—no heat, solder, or flux required. These valves meet NSF/ANSI 61 for use in drinking water systems. They open to allow flow in one direction and close when flow stops or reverses.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

- For Use With: Drinking Water, Steam

- Ball Material: PTFE Plastic

- Spring Material: 316 Stainless Steel

- Seal Material: EPDM Rubber

| For Tube OD | Flow Coefficient (Cv) | Max. Pressure | Max. Steam Pressure | Min. Opening Pressure, psi | Temperature Range, °F | End-to-End Lg. | Each | |

Push to Connect × Push to Connect | ||||||||

|---|---|---|---|---|---|---|---|---|

| 5/8" | 1.4 | 400 psi @ 350° F | 125 psi @ 212° F | 0.5 | 0° to 250° | 4 1/2" | 000000 | 000000 |

| 7/8" | 3.5 | 400 psi @ 350° F | 125 psi @ 212° F | 0.5 | 0° to 250° | 5 1/4" | 0000000 | 00000 |

| 1 1/8" | 6 | 400 psi @ 350° F | 125 psi @ 212° F | 0.5 | 0° to 250° | 6 5/16" | 0000000 | 000000 |

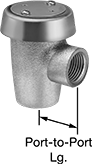

Vacuum-Breaking Valves

Also known as vacuum breakers, these valves have vents that open when pressure drops to relieve vacuum conditions and prevent backward suction from drawing liquid into upstream piping.

Chrome-plated bronze valves are more corrosion resistant than brass valves.

Elbows are designed for intermittent flow. They discharge liquid directly and should not be installed in areas where spillage could cause damage.

- For Use With: Water

- Seal Material: Silicone Rubber

Brass Body | Chrome-Plated Bronze Body | ||||||

|---|---|---|---|---|---|---|---|

| Pipe Size | Max. Pressure | Temperature Range, °F | Port-to-Port Lg. | Each | Each | ||

NPT Female Inlet × NPT Female Outlet | |||||||

| 1/4 | 125 psi @ 70° F | 35° to 180° | 1" | 000000 | 00 | 0000000 | 000000 |

| 3/8 | 125 psi @ 70° F | 35° to 180° | 1" | 000000 | 00 | 0000000 | 00000 |

| 1/2 | 125 psi @ 70° F | 35° to 180° | 1 1/4" | 000000 | 00 | 0000000 | 00000 |

| 1/2 | 125 psi @ 70° F | 35° to 180° | 1 5/16" | 00000000 | 000000 | 000000 | 00 |

| 3/4 | 125 psi @ 70° F | 35° to 180° | 1 1/2" | 00000000 | 00000 | 0000000 | 00000 |

| 1 | 125 psi @ 70° F | 35° to 180° | 1 5/8" | 00000000 | 00000 | 000000 | 00 |

| 1 1/4 | 125 psi @ 70° F | 35° to 180° | 2" | 00000000 | 000000 | 000000 | 00 |

| 1 1/2 | 125 psi @ 70° F | 35° to 180° | 2 1/4" | 00000000 | 000000 | 000000 | 00 |

| 2 | 125 psi @ 70° F | 35° to 180° | 2 3/4" | 00000000 | 000000 | 000000 | 00 |

Vacuum-Breaking Valves with Garden-Hose Fittings

- For Use With: Air, Water

- Seal Material: Rubber

Prevent dirty, contaminated water from backing up into your garden hose line—install these valves between a faucet and a garden hose. Also known as vacuum breakers, these valves have a built-in check valve that blocks backflow, so you can leave your hose in a utility sink full of dirty water without the water going back into the line.

When the check valve is closed, it has vents that open to release the water. This reduces pressure in the line and confirms the valve is working. Because these valves vent water, use them in environments where spilled water won’t cause a problem. This design adheres to ASSE Standard 1011 for valves with a vent.

Mount valves to faucet outlets with a set screw, and easily thread or unthread a hose while the valves stay in place.

Valves comply with Uniform Plumbing Code (UPC) and are CSA certified, so they're safe to use in sanitary plumbing systems because they prevent contamination from flowing backward into your line.

These valves are designed to be used intermittently. They've been tested under ASME A112.1.3, which assumes the valves will not be used for more than 12 hours at a time.

Chrome-plated brass valves are more corrosion resistant than plain brass valves.

Valves with tamper-resistant set screws have a head that breaks off after tightening to prevent valve removal after installation.

Valves that meet NSF/ANSI Standard 372 are certified lead free.

Brass Body | Chrome-Plated Brass Body | |||||||

|---|---|---|---|---|---|---|---|---|

| Hose Size | Max. Pressure | Temperature Range, °F | End-to-End Lg. | Specifications Met | Each | Each | ||

GHT Female × GHT Male | ||||||||

With Set Screw | ||||||||

| 3/4 | 125 psi @ 70° F | 30° to 180° | 1 1/2" | ASSE Standard 1011, CSA Certified, CAN/CSA B64.2, NSF/ANSI 372, UPC Compliant, ASME A112.1.3, ASSE 1001 | 00000000 | 000000 | 00000000 | 000000 |

| 3/4 | 125 psi @ 70° F | 30° to 180° | 1 1/2" | ASSE Standard 1011, CSA Certified, CAN/CSA B64.2, UPC Compliant, ASME A112.1.3, ASSE 1001 | 00000000 | 00000 | 00000000 | 00000 |

With Tamper-Resistant Set Screw | ||||||||

| 3/4 | 125 psi @ 70° F | 30° to 180° | 1 1/2" | ASSE Standard 1011, CSA Certified, CAN/CSA B64.2, NSF/ANSI 372, UPC Compliant, ASME A112.1.3, ASSE 1001 | 00000000 | 00000 | 00000000 | 00000 |

| 3/4 | 125 psi @ 70° F | 30° to 180° | 1 1/2" | ASSE Standard 1011, CSA Certified, CAN/CSA B64.2, UPC Compliant, ASME A112.1.3, ASSE 1001 | 00000000 | 00000 | 00000000 | 00000 |