Filter by

Mounting Position

Material

For Use With

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Capacity

Air Consumption @ Pressure

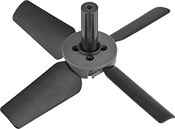

Chip Fans for CNC Machines

|  |  |

Fan Shown Folded |

Shank | Blade | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Dia. | Material | For Spindle Speed, rpm | Closed Dia. | Open Dia. | Material | Mounting Position | Features | Each | ||

| 3/4" | Steel | 4,000 to 7,000 | 2 1/2" | 10 1/4" | Plastic | Horizontal, Vertical | Coolant Hole, Self-Folding Blades | 00000000 | 0000000 | |

Parts Cleaning Vacuum/Blowers

Manual Vacuum/Blowers

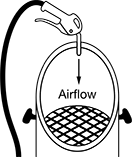

|  |  |  |

Manual | Manual (Top) | Focused Airflow | Replacement Filter |

Vacuum/Blowers | Replacement Filters | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Opening | Overall | Air Inlet (NPT Thread) | Nozzle Connection (NPT Thread) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Cap., gal. | Air Consumption @ Pressure | Dia. | Dp. | Dia. | Ht. | Max. Temp., ° F | Filter Material | Max. Air Inlet Pressure, psi | Pipe Size | Gender | Pipe Size | Gender | Nozzle Max. Operating Pressure, psi | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PVC Housing—Focused Airflow Pattern | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 35 ft³/min @ 90 psi | 7 3/4" | 16 3/16" | 13 3/8" | 39" | 140 | Fiberglass | 150 | 1/4 | Female | 1/4 | Female | 145 | 00000000 | 000000000 | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 35 ft³/min @ 90 psi | 11 3/4" | 16" | 21 3/8" | 39 1/4" | 140 | Fiberglass | 150 | 3/8 | Female | 1/4 | Female | 145 | 00000000 | 00000000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Automatic Vacuum/Blowers

|  |

Automated | Automated (Top) |

|

Circular Airflow |

|

Replacement Filter |

Vacuum/Blowers | Replacement Filters | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Opening | Overall | Air Inlet (NPT Thread) | Outlet (NPT Thread) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Cap., gal. | Air Consumption @ Pressure | Dia. | Dp. | Dia. | Ht. | Max. Temp., ° F | Filter Material | Max. Air Inlet Pressure, psi | Pipe Size | Gender | Pipe Size | Gender | No. of Orifices | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PVC Housing—Circular Airflow Pattern | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 100 ft³/min @ 90 psi | 7 1/2" | 7" | 13 11/16" | 35" | 140 | Fiberglass | 150 | 1/2 | Female | 3/4 | Female | 8 | 00000000 | 000000000 | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 100 ft³/min @ 90 psi | 15" | 12" | 21" | 40" | 140 | Fiberglass | 150 | 1/2 | Female | 1 1/4 | Male | 12 | 00000000 | 00000000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||