Filter by

Wheel Diameter

Power Source

Blade Diameter

Arbor Hole Shape

Export Control Classification Number (ECCN)

REACH

RoHS

U.S.–Mexico–Canada Agreement (USMCA) Qualifying

DFARS Specialty Metals

Power

No-Load Rotational Speed

Cutting Depth

Wheel Included

Blade Included

Blade Location

Cutting Width

Electrical Connection

Maximum Cutting Height

Maximum Cutting Width

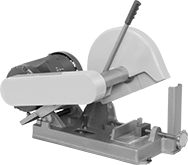

Heavy Duty Electric Bench-Top Chop Saws

Power, hp | Electrical Connection Type | Motor Electrical Phase | For Wheel Dia. | For Arbor Hole Dia. | No-Load Rotational Speed, rpm | Max. Cutting Dp. | Wt., lb. | Cord Lg., ft. | Wheel Included | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

240V AC | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | Hardwire | Three | 10" | 5/8" | 3,450 | 1 1/2" | 80 | 5 | No | 4022A9 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Cold Saws

Electrical | For Blade Pinhole | Max. Cutting | Blade | Single-Phase Motor | Three-Phase Motor | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Connection Type | Connection | No. of Blades | Power, hp | For Blade Dia. | No. of | Dia., mm | Ctr.-to-Ctr., mm | For Arbor Hole Dia., mm | No-Load Rotational Speed, rpm | Ht. | Wd. | Max. Miter Cut Angle (Swivel Direction) | Included | Location | Features | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Heavy Duty (550 lb.) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

240V AC | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Plug In | Straight Blade | 3 | 3 | 14" | 2 | 8.5 11 | 45 63 | 32 | 24 to 120 | 4" | 4" | 45° (Left/Right) | No | Left Side | Emergency Stop, Quick-Release Vise | 8981N11 | 000000000 | 8981N12 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||