Selecting an Immersion Heater

More

Flow-Through Heaters for Water

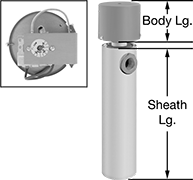

Also known as circulation heaters, these install directly into pipelines to quickly and efficiently heat liquid through direct contact. An adjustable thermostat automatically turns the heater on when the temperature drops below the set temperature and off when it rises above the set temperature. Adjust the set temperature with the screw or dial.

Incoloy heating elements are more corrosion resistant than copper heating elements.

Heating Element | Temp. Control | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wattage, W | Watt Density, W/sq. in. | Current, A | Lg. | Wd. | No. of | Method | Range, °F | Pipe Size | Thread Type | Gender | Wire Connection Type | Each | |

Copper Heating Element with Bronze Body | |||||||||||||

120V AC, Single Phase | |||||||||||||

| 1,500 | 34 | 12.5 | 11 1/4" | 4" | 1 | Screw | 60° to 180° | 1 | NPT | Female | Screw Terminals | 0000000 | 000000000 |

| 2,000 | 47 | 16.7 | 11 3/4" | 4" | 1 | Screw | 60° to 180° | 1 | NPT | Female | Screw Terminals | 0000000 | 00000000 |

240V AC, Single Phase | |||||||||||||

| 3,000 | 51 | 12.5 | 16" | 4" | 1 | Screw | 60° to 180° | 1 | NPT | Female | Screw Terminals | 0000000 | 00000000 |

Incoloy Heating Element with Aluminum Body | |||||||||||||

480V AC, Three Phase | |||||||||||||

| 6,000 | 50 | 7.3 | 28 13/16" | 5 5/8" | 3 | Dial | 60° to 250° | 1 | NPT | Male | Wire Leads | 000000000 | 00000000 |

| 12,000 | 50 | 14.5 | 39 9/16" | 5 5/8" | 3 | Dial | 60° to 250° | 1 | NPT | Male | Wire Leads | 000000000 | 00000000 |

| 18,000 | 50 | 21.7 | 51 5/16" | 5 5/8" | 3 | Dial | 60° to 250° | 1 | NPT | Male | Wire Leads | 000000000 | 00000000 |

| 24,000 | 50 | 29 | 37 5/16" | 8" | 6 | Dial | 60° to 250° | 2 | NPT | Male | Wire Leads | 000000000 | 00000000 |

| 40,000 | 50 | 48 | 55 3/4" | 8" | 6 | Dial | 60° to 250° | 2 | NPT | Male | Wire Leads | 000000000 | 00000000 |

Flow-Through Heaters for Chemical Solutions

Also known as circulation heaters, these install directly into pipelines to quickly and efficiently heat liquid through direct contact. All are designed to heat chemical solutions at much higher watt densities than other immersion heaters without damaging the heating element. An adjustable thermostat automatically turns the heater on when the temperature drops below the set temperature and off when it rises above the set temperature. Adjust the set temperature with the dial. Heaters automatically shut off at 202° F to prevent fire and heating element burnout. The heating element is titanium for excellent resistance to harsh chemicals.

Heating Element | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wattage, W | Watt Density, W/sq. in. | Current, A | Lg. | Wd. | Temp. Control Range, °F | Pipe Size | Thread Type | Gender | Electrical Connection Type | NEMA Style | Environmental Rating | For Use With | Each | |

Titanium Heating Element with 304 Stainless Steel Body | ||||||||||||||

120V AC, Single Phase | ||||||||||||||

| 1,500 | 42 | 12.5 | 15" | 5.7" | 90° to 190° | 1 1/2 | NPT | Female | Plug | 5-15 | NEMA 1 | Ammonium Hydroxide (0-3%), Ammonium Hydroxide (3-6%), Deionized Water, Salt Water, Water | 0000000 | 0000000 |

240V AC, Single Phase | ||||||||||||||

| 3,000 | 84 | 12.5 | 15" | 5.7" | 90° to 190° | 1 1/2 | NPT | Female | Hardwire | __ | NEMA 1 | Ammonium Hydroxide (0-3%), Ammonium Hydroxide (3-6%), Deionized Water, Salt Water, Water | 0000000 | 000000 |

| 4,000 | 112 | 16.7 | 15" | 5.7" | 90° to 190° | 1 1/2 | NPT | Female | Hardwire | __ | NEMA 1 | Ammonium Hydroxide (0-3%), Ammonium Hydroxide (3-6%), Deionized Water, Salt Water, Water | 0000000 | 000000 |

| 6,000 | 167 | 25 | 15" | 5.7" | 90° to 190° | 1 1/2 | NPT | Female | Hardwire | __ | NEMA 1 | Ammonium Hydroxide (0-3%), Ammonium Hydroxide (3-6%), Deionized Water, Salt Water, Water | 0000000 | 000000 |

Flow-Through Heaters for Coolant

Also known as circulation heaters, these install directly into pipelines to quickly and efficiently heat liquid through direct contact. To heat coolant without creating hot spots and damaging the heating element, they have a lower watt density than heaters for water or chemicals. An adjustable thermostat automatically turns the heater on when the temperature drops below the set temperature and off when it rises above the set temperature. Adjust the set temperature with the dial.

Heating Element | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wattage, W | Watt Density, W/sq. in. | Current, A | Lg. | Wd. | No. of | Temp. Control Range, °F | Pipe Size | Thread Type | Gender | Wire Connection Type | For Use With | Each | |

Steel Heating Element with Steel Body | |||||||||||||

120V AC, Single Phase | |||||||||||||

| 500 | 17 | 4.2 | 8 3/8" | 4" | 1 | 150° to 560° | 1 | NPT | Female | Screw Terminals | Ethylene Glycol, Water | 0000000 | 000000000 |

| 750 | 17 | 6.3 | 13" | 4" | 1 | 150° to 560° | 1 | NPT | Female | Screw Terminals | Ethylene Glycol, Water | 0000000 | 00000000 |

240V AC, Single Phase | |||||||||||||

| 1,000 | 18 | 4.2 | 15 1/4" | 4" | 1 | 150° to 560° | 1 | NPT | Female | Screw Terminals | Ethylene Glycol, Water | 0000000 | 00000000 |

Flow-Through Heaters for Air

Tackle high-temperature drying, shrink-wrapping, and plastic welding jobs with your everyday compressed air supply. These heaters connect to your air source on one end and to your process on the other. Control the output temperature by adjusting the incoming airflow or power sent to the heater. The outlet can point upwards, straight, or as much as 10° downwards. Be cautious when positioning it—pointing it further downwards may damage the heating element.

To calculate the wattage needed for your application, multiply your incoming airflow in CFM by the number of degrees you need to increase air temperature, then divide by three.

Thermocouple probes and thermocouple fittings (both sold separately) allow you to use a temperature controller to operate 240V AC heaters. The probe threads into the fitting to measure your air outlet temperature.

Heating Element | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wattage, W | Watt Density | Current, A | Lg. | Wd. | No. of | Max. Air Input Temp., °F | Max. Air Output Temp., ° F | Max. Input Airflow, cfm | Pipe Size | Thread Type | Gender | Wire Connection Type | Each | |

Ceramic Heating Element with Copper Body | ||||||||||||||

120V AC, Single Phase | ||||||||||||||

| 400 | 89 W/linear in. | 3.3 | 5" | 1/2" | 1 | 250° | 1,000 | 10 | 1/8 | NPT | Female | Wire Leads | 0000000 | 0000000 |

| 650 | 87 W/linear in. | 5.4 | 8" | 1/2" | 1 | 250° | 1,000 | 10 | 1/8 | NPT | Female | Wire Leads | 0000000 | 000000 |

| 750 | 136 W/linear in. | 6.2 | 6" | 3/4" | 1 | 250° | 1,000 | 20 | 1/4 | NPT | Female | Wire Leads | 0000000 | 000000 |

| 1,250 | 132 W/linear in. | 10.4 | 10" | 3/4" | 1 | 250° | 1,000 | 20 | 1/4 | NPT | Female | Wire Leads | 0000000 | 000000 |

240V AC, Single Phase | ||||||||||||||

| 1,000 | 182 W/linear in. | 4.1 | 6" | 1 1/4" | 1 | 250° | 1,000 | 50 | 1/2 | NPT | Female | Wire Leads | 0000000 | 000000 |

| 2,500 | 333 W/linear in. | 10.4 | 8" | 1 1/4" | 1 | 250° | 1,000 | 50 | 1/2 | NPT | Female | Wire Leads | 0000000 | 000000 |

| 4,000 | 348 W/linear in. | 16.6 | 12" | 1 1/4" | 1 | 250° | 1,000 | 50 | 1/2 | NPT | Female | Wire Leads | 0000000 | 000000 |

Probe | Probe Connection | Cable | ||||||

|---|---|---|---|---|---|---|---|---|

| Lg. | Dia. | Pipe Size | Thread Type | Gender | Lg., ft. | Material | Each | |

Type J | ||||||||

| 1" | 3/16" | 1/4 | NPT | Male | 6 | Fiberglass | 0000000 | 0000000 |

Air Inlet | Air Outlet | Thermocouple Probe Connection | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Gender | Pipe Size | Thread Type | Gender | Pipe Size | Thread Type | Gender | Each | |

| 1/2 | Male | 1/2 | NPT | Female | 1/4 | NPT | Female | 0000000 | 0000000 |

Hot and Cold Tubes for Supplied-Air Respirators for Plant Air Lines

Adjust the temperature of the air flowing into your respirator. These tubes rapidly spin the air from your supply line to separate it into hot and cold streams. Turn a knob to control how much air from each stream flows into your respirator.

| OD | Lg. | Air Temp. Increase, °F | Air Temp. Reduction, °F | Material | Belt Material | Connection Type | Quick-Disconnect Shape | Coupling Size | Includes | Features | Each | |

For Heating/Cooling | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1" | 9" | 0° to 25° | 0° to 30° | Aluminum | Polypropylene Fabric | Quick Disconnect | Industrial | 1/4 | Cable Tie, Heat Shield | Temperature Control Valve | 00000000 | 0000000 |