Filter by

Plunger Locking Type

Body Material

Nose Material

End Type

Handle Material

Shaft Type

Export Control Classification Number (ECCN)

Double Shear Breaking Strength

Finish

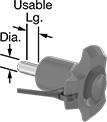

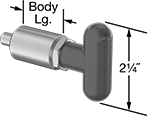

T-Handle Weld-On Retractable Spring Plungers

|

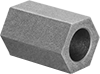

Spring Plungers | Replacement Barrel Sleeves | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Nose | Body | Handle | Nonlocking | Twist-to-Lock | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Extended Lg. | Dia. | Material | Wd. | Lg. | Material | Lg. | Each | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.25" | Steel | 1" | 1.5" | Plastic | 2 1/4" | 90222A797 | 000000 | 90222A312 | 000000 | 90222A804 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.375" | Steel | 1" | 1.5" | Plastic | 2 1/4" | 90222A798 | 00000 | 90222A503 | 00000 | 90222A804 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.5" | Steel | 1" | 1.5" | Plastic | 2 1/4" | 90222A799 | 00000 | 90222A518 | 00000 | 90222A804 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.5" | Steel | 1" | 2.25" | Plastic | 2 1/4" | 90222A801 | 00000 | 90222A548 | 00000 | 90222A805 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.5" | Steel | 1" | 4.5" | Plastic | 2 1/4" | 90222A803 | 00000 | ——— | 0 | 90222A806 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.625" | Steel | 1" | 2.25" | Plastic | 2 1/4" | 90222A802 | 00000 | 90222A666 | 00000 | 90222A805 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.625" | 0.375" | Steel | 1" | 1.5" | Plastic | 2 1/4" | 90222A112 | 00000 | ——— | 0 | 90222A804 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.625" | 0.5" | Steel | 1" | 1.5" | Plastic | 2 1/4" | 90222A116 | 00000 | ——— | 0 | 90222A804 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.625" | 0.5" | Steel | 1" | 3" | Plastic | 2 1/4" | 90222A118 | 00000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.685" | 0.5" | Steel | 1" | 1.5" | Plastic | 2 1/4" | ——— | 0 | 90222A525 | 00000 | 90222A804 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.688" | 0.5" | Steel | 1" | 1.5" | Plastic | 2 1/4" | 90222A800 | 00000 | ——— | 0 | 90222A804 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.375" | 18-8 Stainless Steel | 1" | 1.5" | Plastic | 2 1/4" | 91712A101 | 00000 | 91712A335 | 00000 | 91712A582 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.5" | 18-8 Stainless Steel | 1" | 1.5" | Plastic | 2 1/4" | 91712A119 | 00000 | 91712A351 | 00000 | 91712A582 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.5" | 18-8 Stainless Steel | 1" | 2.25" | Plastic | 2 1/4" | 91712A155 | 00000 | 91712A383 | 00000 | 91712A583 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.625" | 18-8 Stainless Steel | 1" | 2.25" | Plastic | 2 1/4" | 91712A581 | 00000 | 91712A414 | 00000 | 91712A583 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

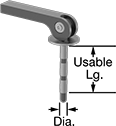

Clamping Quick-Release Pins

Corrosion-Resistant Stainless Steel with Plastic Lanyard

Usable Lg., mm | Dia. at Extended Ball Ht., mm | Double Shear Breaking Strength, lbf | Min. Hardness | Handle Material | Ball Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6 mm Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 5 | 7 | 4,700 | Brinell 150 | Plastic | Stainless Steel | 93042A510 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 to 10 | 7 | 4,700 | Brinell 150 | Plastic | Stainless Steel | 93042A540 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

8 mm Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 5 | 9.5 | 8,500 | Brinell 150 | Plastic | Stainless Steel | 93042A570 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 to 10 | 9.5 | 8,500 | Brinell 150 | Plastic | Stainless Steel | 93042A600 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

10 mm Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 5 | 12 | 13,400 | Brinell 150 | Plastic | Stainless Steel | 93042A630 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 to 10 | 12 | 13,400 | Brinell 150 | Plastic | Stainless Steel | 93042A660 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12 mm Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 to 10 | 14 | 19,500 | Brinell 150 | Plastic | Stainless Steel | 93042A720 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Expanding-Diameter Quick-Release Pins

Corrosion-Resistant Stainless Steel

|

Usable Lg. | Double Shear Breaking Strength, lbf | Min. Hardness | Handle Color | Handle Material | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

High-Strength 17-4 PH Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 8,000 | Not Rated | Black | Aluminum | 97787A661 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 8,000 | Not Rated | Black | Aluminum | 97787A662 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5/16" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 12,500 | Not Rated | Black | Aluminum | 97787A672 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/8" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 18,000 | Not Rated | Black | Aluminum | 97787A681 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 18,000 | Not Rated | Black | Aluminum | 97787A682 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 18,000 | Not Rated | Black | Aluminum | 97787A683 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/2" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 32,000 | Not Rated | Black | Aluminum | 97787A691 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 32,000 | Not Rated | Black | Aluminum | 97787A692 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 32,000 | Not Rated | Black | Aluminum | 97787A693 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Weld-on-Mount Catches for Ball-Nose and Long-Nose Spring Plungers

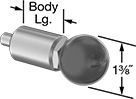

Ball-Grip Weld-On Retractable Spring Plungers

|

Spring Plungers | Replacement Barrel Sleeves | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Nose | Body | Handle | Nonlocking | Twist-to-Lock | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Extended Lg. | Dia. | Material | Wd. | Lg. | Material | Lg. | Each | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.25" | Steel | 1" | 1.5" | Plastic | 1 3/8" | 90222A809 | 000000 | 90222A222 | 000000 | 90222A804 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.375" | Steel | 1" | 1.5" | Plastic | 1 3/8" | 90222A810 | 00000 | 90222A625 | 00000 | 90222A804 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.5" | Steel | 1" | 1.5" | Plastic | 1 3/8" | 90222A811 | 00000 | 90222A643 | 00000 | 90222A804 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.5" | Steel | 1" | 2.25" | Plastic | 1 3/8" | 90222A813 | 00000 | 90222A679 | 00000 | 90222A805 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.5" | Steel | 1" | 4.5" | Plastic | 1 3/8" | 90222A815 | 00000 | ——— | 0 | 90222A806 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.625" | Steel | 1" | 2.25" | Plastic | 1 3/8" | 90222A814 | 00000 | 90222A447 | 00000 | 90222A805 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.625" | 0.375" | Steel | 1" | 1.5" | Plastic | 1 3/8" | 90222A415 | 00000 | ——— | 0 | 90222A804 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.625" | 0.375" | Steel | 1" | 3" | Plastic | 1 3/8" | 90222A423 | 00000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.625" | 0.5" | Steel | 1" | 1.5" | Plastic | 1 3/8" | 90222A419 | 00000 | ——— | 0 | 90222A804 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.688" | 0.5" | Steel | 1" | 1.5" | Plastic | 1 3/8" | 90222A812 | 00000 | 90222A343 | 00000 | 90222A804 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.375" | 18-8 Stainless Steel | 1" | 1.5" | Plastic | 1 3/8" | 91712A222 | 00000 | 91712A443 | 00000 | 91712A582 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.5" | 18-8 Stainless Steel | 1" | 1.5" | Plastic | 1 3/8" | 91712A240 | 00000 | 91712A461 | 00000 | 91712A582 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.5" | 18-8 Stainless Steel | 1" | 2.25" | Plastic | 1 3/8" | 91712A276 | 00000 | 91712A497 | 00000 | 91712A583 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.625" | 18-8 Stainless Steel | 1" | 2.25" | Plastic | 1 3/8" | ——— | 0 | 91712A321 | 00000 | 91712A583 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

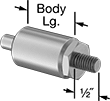

Add-a-Handle Weld-On Retractable Spring Plungers

Spring Plungers | Replacement Barrel Sleeves | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Nose | Body | Handle End Thread | Nonlocking | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Extended Lg. | Dia. | Material | Wd. | Lg. | Size | Lg. | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.375" | Steel | 1" | 1.5" | 3/8"-16 | 1/2" | 90222A742 | 000000 | 90222A804 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.5" | Steel | 1" | 1.5" | 3/8"-16 | 1/2" | 90222A760 | 00000 | 90222A804 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.5" | Steel | 1" | 2.25" | 3/8"-16 | 1/2" | 90222A796 | 00000 | 90222A805 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.375" | 18-8 Stainless Steel | 1" | 1.5" | 3/8"-16 | 1/2" | 91712A556 | 00000 | 91712A582 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.5" | 18-8 Stainless Steel | 1" | 1.5" | 3/8"-16 | 1/2" | 91712A564 | 00000 | 91712A582 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.5" | 18-8 Stainless Steel | 1" | 2.25" | 3/8"-16 | 1/2" | 91712A580 | 00000 | 91712A583 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

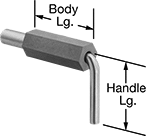

L-Handle Weld-On Retractable Spring Plungers

Spring Plungers | Weld-On Catches | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Nose | Nose Force, lbf | Body | Handle | Nonlocking | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Extended Lg. | Dia. | Extended | Compressed | Material | Wd. | Lg. | Material | Lg. | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.38" | 0.16" | 0.5 | 2.5 | Steel | 0.25" | 0.88" | Steel | 3/4" | 8473A11 | 000000 | 8473A21 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.56" | 0.24" | 0.8 | 3.8 | Steel | 0.375" | 1.47" | Steel | 1" | 8473A12 | 00000 | 8473A22 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.75" | 0.32" | 1 | 5 | Steel | 0.5" | 1.42" | Steel | 1 3/8" | 8473A13 | 00000 | 8473A23 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 0.38" | 1 | 5 | Steel | 0.625" | 2.11" | Steel | 1 3/8" | 8473A14 | 00000 | 8473A24 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.38" | 0.16" | 0.5 | 2.5 | 18-8 Stainless Steel | 0.25" | 0.88" | 18-8 Stainless Steel | 3/4" | 8473A31 | 00000 | 8473A41 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.56" | 0.24" | 3.8 | 3.8 | 18-8 Stainless Steel | 0.375" | 1.47" | 18-8 Stainless Steel | 1" | 8473A32 | 00000 | 8473A42 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.75" | 0.32" | 1 | 5 | 18-8 Stainless Steel | 0.5" | 1.42" | 18-8 Stainless Steel | 1 3/8" | 8473A33 | 00000 | 8473A43 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 0.38" | 1 | 5 | 18-8 Stainless Steel | 0.625" | 2.11" | 18-8 Stainless Steel | 1 3/8" | 8473A34 | 00000 | 8473A44 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||