How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

Copper-Nickel Unthreaded Pipe

- For Use With: Air, Natural Gas, Oil, Water, Salt Water

- Pressure Class : 200

- Specifications Met: MIL-T-16420

- Fittings: Use Class 200 copper-nickel

Designed for salt water applications, this pipe is made of copper-nickel, which has excellent resistance to stress cracking and better corrosion resistance than most stainless steel alloys. Pipe is also known as Pressure Class 200 pipe. Weld it to fittings and additional lengths of pipe. Welded connections are stronger than threaded connections and less likely to leak. Pipe is seamless, which provides a smooth interior for unrestricted flow.

| Lg., ft. | Wall Thick. | Construction | Each | |

1 Pipe Size | ||||

|---|---|---|---|---|

| 1 | 0.065" | Seamless | 0000000 | 000000 |

| 3 | 0.065" | Seamless | 0000000 | 000000 |

| 6 | 0.065" | Seamless | 0000000 | 000000 |

1 1/2 Pipe Size | ||||

| 1 | 0.072" | Seamless | 0000000 | 00000 |

| 3 | 0.072" | Seamless | 0000000 | 000000 |

| 6 | 0.072" | Seamless | 0000000 | 000000 |

2 Pipe Size | ||||

| 1 | 0.083" | Seamless | 0000000 | 000000 |

| 3 | 0.083" | Seamless | 0000000 | 000000 |

| 6 | 0.083" | Seamless | 0000000 | 000000 |

2 1/2 Pipe Size | ||||

| 1 | 0.083" | Seamless | 0000000 | 000000 |

| 3 | 0.083" | Seamless | 0000000 | 000000 |

| 6 | 0.083" | Seamless | 0000000 | 000000 |

3 Pipe Size | ||||

| 1 | 0.095" | Seamless | 0000000 | 000000 |

| 3 | 0.095" | Seamless | 0000000 | 000000 |

| 6 | 0.095" | Seamless | 0000000 | 000000 |

4 Pipe Size | ||||

| 1 | 0.109" | Seamless | 0000000 | 000000 |

| 3 | 0.109" | Seamless | 0000000 | 000000 |

| 6 | 0.109" | Seamless | 0000000 | 00000000 |

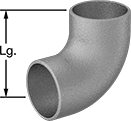

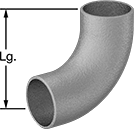

Copper-Nickel Butt-Weld Pipe Fittings

Fittings weld flush against pipe, creating a strong connection that permits maximum flow. Fittings are also known as Pressure Class 200 fittings. They are copper-nickel, which has excellent resistance to stress cracking and better corrosion resistance than most stainless steel alloys. They are often used in highly-corrosive environments, such as salt water applications.

- For Use With: Air, Natural Gas, Oil, Water, Salt Water

- Pressure Class: 200

- Military Specifications Met: NAVSEA 810-1385880

- Pipe: Use Class 200 copper-nickel

- For Use With: Air, Natural Gas, Oil, Water, Salt Water

- Pressure Class: 200

- Military Specifications Met: NAVSEA 810-1385880

- Pipe: Use Class 200 copper-nickel

- For Use With: Air, Natural Gas, Oil, Water, Salt Water

- Pressure Class: 200

- Military Specifications Met: NAVSEA 810-1385880

- Pipe: Use Class 200 copper-nickel