Filter by

Application

System of Measurement

Material

Diameter

Wire Rope Construction

Weight Capacity

Required Installation Tool

For Pin Usable Length

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Specifications Met

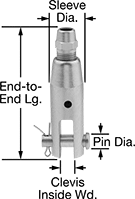

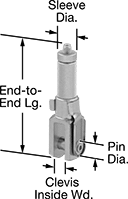

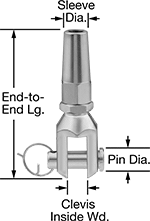

Clevis-End Plug-Lock Wire Rope End Fittings—For Lifting

For Wire Rope | Steel | Zinc-Plated Steel | 316 Stainless Steel | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Dia. | Construction | End-to-End Lg. | Clevis Inside Wd. | Sleeve Dia. | Pin Dia. | Wt. Cap., lb. | Specs. Met | Each | Each | Each | ||||

| 3/64" to 1/16" | 6 × 19 Fiber Core 6 × 19 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 2 1/16" | 3/16" | 1/2" | 3/16" | 90 | ASME B30.26 ASME B30.9 | 0000000 | 000000 | 0000000 | 000000 | 0000000 | 000000 | |

| 5/64" to 3/32" | 6 × 19 Fiber Core 6 × 19 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 2 1/2" | 1/4" | 5/8" | 1/4" | 100 | ASME B30.26 ASME B30.9 | 0000000 | 00000 | 0000000 | 00000 | 0000000 | 00000 | |

| 1/8" | 6 × 19 Fiber Core 6 × 19 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 2 1/2" | 1/4" | 5/8" | 1/4" | 300 | ASME B30.26 ASME B30.9 | 0000000 | 00000 | 0000000 | 00000 | 0000000 | 00000 | |

| 3/16" | 6 × 19 Fiber Core 6 × 19 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 3 1/8" | 5/16" | 3/4" | 5/16" | 700 | ASME B30.26 ASME B30.9 | 00000000 | 00000 | 00000000 | 00000 | 00000000 | 00000 | |

| 1/4" | 6 × 19 Fiber Core 6 × 19 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 3 3/4" | 3/8" | 15/16" | 3/8" | 1,300 | ASME B30.26 ASME B30.9 | 00000000 | 00000 | 00000000 | 00000 | 00000000 | 00000 | |

| 3/8" | 6 × 19 Fiber Core 6 × 19 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 4 13/16" | 7/16" | 1 3/16" | 1/2" | 3,000 | ASME B30.26 ASME B30.9 | 00000000 | 00000 | 00000000 | 00000 | 00000000 | 000000 | |

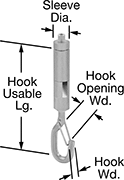

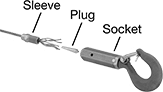

Hook-End Feed-Through Wire Rope End Fittings—Not for Lifting

For Wire Rope | Hook | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Dia. | Construction | Sleeve Dia. | Usable Lg. | Opening Wd. | Wd. | Material | Wt. Cap., lb. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Nickel-Plated Brass | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/64" to 1/16" | 7 × 7 Strand Core 7 × 19 Strand Core | 11/32" | 2 31/32" | 17/32" | 1/4" | Steel | 25 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/64" to 3/32" | 7 × 7 Strand Core 7 × 19 Strand Core | 15/32" | 3 9/16" | 17/32" | 1/4" | Steel | 50 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/32" to 1/8" | 7 × 7 Strand Core 7 × 19 Strand Core | 19/32" | 4 7/32" | 17/32" | 1/4" | Steel | 110 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

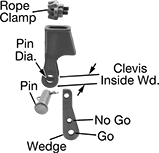

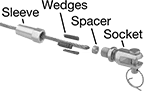

Wedge-Lock Wire Rope End Fittings—For Lifting

Fittings | Replacement Wedges | Replacement Pins | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Wire Rope | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Dia. | Construction | Clevis Inside Wd. | For Pin Dia. | Req. Torque, ft·lbf | Rope Cap. Adjustment Factor | Specs. Met | Each | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Red Painted Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 6 × 19 Fiber Core 6 × 19 IWRC 6 × 26 IWRC 6 × 37 IWRC 6 × 7 Fiber Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core 18 × 7 IWRC 19 × 7 Strand Core | 13/16" | 13/16" | 45 | 80% | ASME B30.26 Fed. Spec. RR-S-550 | 0000000 | 0000000 | 0000000 | 000000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 6 × 19 Fiber Core 6 × 19 IWRC 6 × 26 IWRC 6 × 37 IWRC 6 × 7 Fiber Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core 18 × 7 IWRC 19 × 7 Strand Core | 1" | 1" | 65 | 80% | ASME B30.26 Fed. Spec. RR-S-550 | 0000000 | 000000 | 0000000 | 00000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 6 × 19 Fiber Core 6 × 19 IWRC 6 × 26 IWRC 6 × 37 IWRC 6 × 7 Fiber Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core 18 × 7 IWRC 19 × 7 Strand Core | 1 1/4" | 1 7/32" | 95 | 80% | ASME B30.26 Fed. Spec. RR-S-550 | 0000000 | 000000 | 0000000 | 00000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 6 × 19 Fiber Core 6 × 19 IWRC 6 × 26 IWRC 6 × 37 IWRC 6 × 7 Fiber Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core 18 × 7 IWRC 19 × 7 Strand Core | 1 1/2" | 1 13/32" | 130 | 80% | ASME B30.26 Fed. Spec. RR-S-550 | 0000000 | 000000 | 0000000 | 00000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Clevis-End Sleeve-Grip Wire Rope End Fittings—Not for Lifting

|  |

For Wire Rope | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Dia. | Construction | End-to-End Lg. | Clevis Inside Wd. | Sleeve Dia. | Pin Dia. | Wt. Cap. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 1 × 19 Strand Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 2 1/2" | 1/4" | 7/16" | 1/4" | Not Rated | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/32" | 1 × 19 Strand Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 2 7/8" | 5/16" | 1/2" | 5/16" | Not Rated | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 1 × 19 Strand Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 3 1/4" | 7/16" | 9/16" | 7/16" | Not Rated | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 1 × 19 Strand Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 3 3/4" | 1/2" | 5/8" | 1/2" | Not Rated | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 1 × 19 Strand Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 4 11/16" | 9/16" | 3/4" | 9/16" | Not Rated | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 1 × 19 Strand Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 5 1/4" | 11/16" | 1" | 11/16" | Not Rated | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

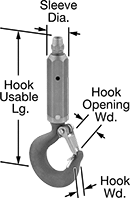

Swivel-Hook-End Plug-Lock Wire Rope End Fittings—For Lifting

For Wire Rope | Hook | Steel | Zinc-Plated Steel | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Dia. | Construction | Sleeve Dia. | Usable Lg. | Opening Wd. | Wd. | Fabrication | Material | Wt. Cap., lb. | Specs. Met | Each | Each | |||

| 3/16" | 6 × 19 Fiber Core 6 × 19 IWRC 6 × 26 IWRC 6 × 37 IWRC 6 × 7 Fiber Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 3/4" | 5 31/32" | 1" | 9/16" | Forged | Steel | 665 | ASME B30.26 | 0000000 | 0000000 | 0000000 | 0000000 | |

| 1/4" | 6 × 19 Fiber Core 6 × 19 IWRC 6 × 26 IWRC 6 × 37 IWRC 6 × 7 Fiber Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 15/16" | 6 27/32" | 1 1/16" | 5/8" | Forged | Steel | 1,175 | ASME B30.26 | ——— | 0 | 0000000 | 000000 | |

| 1/4" | 6 × 19 Fiber Core 6 × 19 IWRC 6 × 26 IWRC 6 × 37 IWRC 6 × 7 Fiber Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 15/16" | 7 7/16" | 1 1/16" | 5/8" | Forged | Steel | 1,175 | ASME B30.26 | 0000000 | 000000 | ——— | 0 | |

| 5/16" | 6 × 19 Fiber Core 6 × 19 IWRC 6 × 26 IWRC 6 × 37 IWRC 6 × 7 Fiber Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 15/16" | 7 19/32" | 1 1/8" | 3/4" | Forged | Steel | 1,830 | ASME B30.26 | ——— | 0 | 0000000 | 000000 | |

| 3/8" | 6 × 19 Fiber Core 6 × 19 IWRC 6 × 26 IWRC 6 × 37 IWRC 6 × 7 Fiber Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 1 1/8" | 8 17/32" | 1 1/4" | 27/32" | Forged | Steel | 2,620 | ASME B30.26 | 0000000 | 000000 | 0000000 | 000000 | |

Clevis-End Feed-Through Wire Rope End Fittings—Not for Lifting

For Wire Rope | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Dia. | Construction | End-to-End Lg. | Clevis Inside Wd. | Sleeve Dia. | Pin Dia. | Wt. Cap., lb. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Nickel-Plated Brass | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/64" to 1/16" | 7 × 7 Strand Core 7 × 19 Strand Core | 1 23/32" | 5/16" | 9/16" | 5/16" | 25 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/16" to 3/32" | 7 × 7 Strand Core 7 × 19 Strand Core | 2 7/32" | 1/4" | 15/32" | 1/4" | 50 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/32" to 1/8" | 7 × 7 Strand Core 7 × 19 Strand Core | 3 17/32" | 3/8" | 19/32" | 3/8" | 110 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Clevis-End Roller Swage Wire Rope End Fittings—Not for Lifting

Fittings | Dies | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Wire Rope | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Dia. | Construction | End-to-Eye Lg. | Clevis Inside Wd. | Shank Dia. | Wt. Cap., lb. | For Pin Dia. | Mil. Spec. | Each | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/16" | 1 × 7 Strand Core 1 × 19 Strand Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 1 5/8" | 1/8" | 3/16" | 90 | 3/16" | MS20667 | 0000000 | 000000 | 2 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/32" | 1 × 7 Strand Core 1 × 19 Strand Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 2" | 1/8" | 1/4" | 100 | 3/16" | MS20667 | 0000000 | 00000 | 2 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 1 × 7 Strand Core 1 × 19 Strand Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 2 3/8" | 1/4" | 1/4" | 400 | 3/16" | MS20667 | 0000000 | 00000 | 2 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/32" | 1 × 7 Strand Core 1 × 19 Strand Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 2 11/16" | 1/4" | 5/16" | 500 | 1/4" | MS20667 | 0000000 | 00000 | 2 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 1 × 7 Strand Core 1 × 19 Strand Core 6 × 37 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core 18 × 7 IWRC | 3 1/8" | 5/16" | 3/8" | 800 | 5/16" | MS20667 | 0000000 | 00000 | 2 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 1 × 7 Strand Core 1 × 19 Strand Core 6 × 37 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core 18 × 7 IWRC | 3 13/16" | 5/16" | 1/2" | 1,400 | 3/8" | MS20667 | 0000000 | 00000 | 2 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||