Wire Rope Clamp and Thimble Kits—Not for Lifting

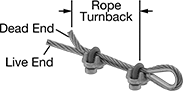

Kits include clamps and thimbles to protect the inside of wire rope loops from fraying. Clamps must be oriented with the saddle on the long (live) end and U-bolt on the short (dead) end.

Galvanized steel and iron clamps and thimbles are corrosion resistant.

18-8 stainless steel clamps and thimbles are chemical resistant.

Warning: Test all assemblies for required strength before use. Do not use with coated rope unless the coating is removed.

Clamp | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Wire Rope Dia. | No. of Clamps | Rope Turnback | For Wire Rope Construction | Wd. | Ht. | Thick. | No. of Thimbles | Fabrication | Required Torque, ft.-lbs. | Capacity | Specifications Met | Each | |

Galvanized Steel Clamps with Galvanized Steel Thimble | |||||||||||||

| 1/8" | 2 | 3 1/4" | 1 × 7 Strand Core 1 × 19 Strand Core 6 × 7 Fiber Core 6 × 19 IWRC 6 × 19 Fiber Core 6 × 26 IWRC 6 × 37 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core 18 × 7 IWRC | 7/8" | 31/32" | 3/8" | 1 | Forged | 4.5 | Not Rated | Fed. Spec. FF-C-450 | 0000000 | 00000 |

| 3/16" | 2 | 3 3/4" | 1 × 7 Strand Core 1 × 19 Strand Core 6 × 7 Fiber Core 6 × 19 IWRC 6 × 19 Fiber Core 6 × 26 IWRC 6 × 37 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core 18 × 7 IWRC | 1" | 1 5/32" | 7/16" | 1 | Forged | 7.5 | Not Rated | Fed. Spec. FF-C-450 | 0000000 | 0000 |

| 1/4" | 2 | 4 3/4" | 1 × 7 Strand Core 1 × 19 Strand Core 6 × 7 Fiber Core 6 × 19 IWRC 6 × 19 Fiber Core 6 × 26 IWRC 6 × 37 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core 18 × 7 IWRC 19 × 7 Strand Core | 1 1/4" | 1 13/32" | 9/16" | 1 | Forged | 15 | Not Rated | Fed. Spec. FF-C-450 | 0000000 | 00000 |

| 5/16" | 2 | 5 1/4" | 1 × 7 Strand Core 1 × 19 Strand Core 6 × 7 Fiber Core 6 × 19 IWRC 6 × 19 Fiber Core 6 × 26 IWRC 6 × 37 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core 18 × 7 IWRC 19 × 7 Strand Core | 1 9/16" | 1 13/16" | 11/16" | 1 | Forged | 30 | Not Rated | Fed. Spec. FF-C-450 | 0000000 | 00000 |

| 3/8" | 2 | 6 1/2" | 1 × 7 Strand Core 1 × 19 Strand Core 6 × 7 Fiber Core 6 × 19 IWRC 6 × 19 Fiber Core 6 × 26 IWRC 6 × 37 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core 18 × 7 IWRC 19 × 7 Strand Core | 1 7/8" | 2 1/4" | 7/8" | 1 | Forged | 45 | Not Rated | Fed. Spec. FF-C-450 | 0000000 | 00000 |

| 7/16" | 2 | 7" | 1 × 7 Strand Core 1 × 19 Strand Core 6 × 7 Fiber Core 6 × 19 IWRC 6 × 19 Fiber Core 6 × 26 IWRC 6 × 37 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core 18 × 7 IWRC 19 × 7 Strand Core | 2 1/16" | 2 3/8" | 7/8" | 1 | Forged | 65 | Not Rated | Fed. Spec. FF-C-450 | 0000000 | 00000 |

| 1/2" | 3 | 11 1/2" | 1 × 7 Strand Core 1 × 19 Strand Core 6 × 7 Fiber Core 6 × 19 IWRC 6 × 19 Fiber Core 6 × 26 IWRC 6 × 37 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core 18 × 7 IWRC 19 × 7 Strand Core | 2 1/16" | 2 41/64" | 7/8" | 1 | Forged | 65 | Not Rated | Fed. Spec. FF-C-450 | 0000000 | 00000 |

| 5/8" | 3 | 12" | 1 × 7 Strand Core 1 × 19 Strand Core 6 × 7 Fiber Core 6 × 19 IWRC 6 × 19 Fiber Core 6 × 26 IWRC 6 × 37 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core 18 × 7 IWRC 19 × 7 Strand Core | 2 3/8" | 3 1/4" | 1 1/16" | 1 | Forged | 95 | Not Rated | Fed. Spec. FF-C-450 | 0000000 | 00000 |

| 3/4" | 4 | 18" | 1 × 7 Strand Core 1 × 19 Strand Core 6 × 7 Fiber Core 6 × 19 IWRC 6 × 19 Fiber Core 6 × 26 IWRC 6 × 37 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core 18 × 7 IWRC 19 × 7 Strand Core | 2 13/16" | 3 3/8" | 2 1/4" | 1 | Forged | 100 | Not Rated | Fed. Spec. FF-C-450 | 0000000 | 00000 |

Galvanized Iron Clamps with Galvanized Steel Thimble | |||||||||||||

| 1/16" | 2 | 2 3/4" | 1 × 7 Strand Core 1 × 19 Strand Core 3 × 7 IWRC 3 × 7 Hollow Core 6 × 7 Fiber Core 7 × 7 IWRC 7 × 7 Strand Core | 11/16" | 13/16" | 7/16" | 1 | Cast | __ | Not Rated | Fed. Spec. FF-C-450 | 0000000 | 0000 |

| 1/8" | 3 | 4 3/4" | 1 × 7 Strand Core 1 × 19 Strand Core 6 × 7 Fiber Core 6 × 19 IWRC 6 × 19 Fiber Core 6 × 26 IWRC 6 × 37 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 7/8" | 31/32" | 3/8" | 1 | Cast | 3 | Not Rated | Fed. Spec. FF-C-450 | 0000000 | 0000 |

| 3/16" | 3 | 5 1/2" | 1 × 7 Strand Core 1 × 19 Strand Core 6 × 7 Fiber Core 6 × 19 IWRC 6 × 19 Fiber Core 6 × 26 IWRC 6 × 37 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 1" | 1 5/32" | 7/16" | 1 | Cast | 4.5 | Not Rated | Fed. Spec. FF-C-450 | 0000000 | 0000 |

| 1/4" | 3 | 7" | 1 × 7 Strand Core 1 × 19 Strand Core 6 × 7 Fiber Core 6 × 19 IWRC 6 × 19 Fiber Core 6 × 26 IWRC 6 × 37 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 1 1/4" | 1 13/32" | 9/16" | 1 | Cast | 15 | Not Rated | Fed. Spec. FF-C-450 | 0000000 | 0000 |

| 5/16" | 3 | 7 3/4" | 1 × 7 Strand Core 1 × 19 Strand Core 6 × 7 Fiber Core 6 × 19 IWRC 6 × 19 Fiber Core 6 × 26 IWRC 6 × 37 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core 18 × 7 IWRC 19 × 7 Strand Core | 1 9/16" | 1 13/16" | 11/16" | 1 | Cast | 15 | Not Rated | Fed. Spec. FF-C-450 | 0000000 | 0000 |

| 3/8" | 3 | 9 1/2" | 1 × 7 Strand Core 1 × 19 Strand Core 6 × 7 Fiber Core 6 × 19 IWRC 6 × 19 Fiber Core 6 × 26 IWRC 6 × 37 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 1 7/8" | 2 1/4" | 7/8" | 1 | Cast | 30 | Not Rated | Fed. Spec. FF-C-450 | 0000000 | 0000 |

| 7/16" | 3 | 10 1/4" | 1 × 7 Strand Core 1 × 19 Strand Core 6 × 7 Fiber Core 6 × 19 IWRC 6 × 19 Fiber Core 6 × 26 IWRC 6 × 37 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 2 1/16" | 2 3/8" | 7/8" | 1 | Cast | 40 | Not Rated | Fed. Spec. FF-C-450 | 0000000 | 00000 |

| 1/2" | 4 | 15 1/4" | 1 × 7 Strand Core 1 × 19 Strand Core 6 × 7 Fiber Core 6 × 19 IWRC 6 × 19 Fiber Core 6 × 26 IWRC 6 × 37 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 2 1/16" | 2 41/64" | 7/8" | 1 | Cast | 45 | Not Rated | Fed. Spec. FF-C-450 | 0000000 | 00000 |

| 5/8" | 4 | 16" | 1 × 7 Strand Core 1 × 19 Strand Core 6 × 7 Fiber Core 6 × 19 IWRC 6 × 19 Fiber Core 6 × 26 IWRC 6 × 37 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 2 3/8" | 3 1/4" | 1 1/16" | 1 | Cast | 75 | Not Rated | Fed. Spec. FF-C-450 | 0000000 | 00000 |

| 3/4" | 5 | 22 1/4" | 1 × 7 Strand Core 1 × 19 Strand Core 6 × 7 Fiber Core 6 × 19 IWRC 6 × 19 Fiber Core 6 × 26 IWRC 6 × 37 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 2 9/16" | 3 5/16" | 1 1/16" | 1 | Cast | 75 | Not Rated | Fed. Spec. FF-C-450 | 0000000 | 00000 |

18-8 Stainless Steel Clamps with 18-8 Stainless Steel Thimble | |||||||||||||

| 1/16" | 1 | 3 1/4" | 1 × 7 Strand Core 1 × 19 Strand Core 3 × 7 IWRC 3 × 7 Hollow Core 6 × 7 Fiber Core 6 × 19 IWRC 6 × 19 Fiber Core 6 × 26 IWRC 6 × 37 IWRC 7 × 7 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core 18 × 7 IWRC 19 × 7 Strand Core | 17/32" | 13/32" | 9/16" | 1 | Cast | __ | 80% of the Rope's Capacity | __ | 0000000 | 0000 |

| 1/8" | 2 | 3 1/4" | 1 × 19 Strand Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 5/8" | 13/16" | 9/16" | 1 | Cast | Not Rated | 80% of the Rope's Capacity | __ | 0000000 | 0000 |

| 3/16" | 2 | 3 3/4" | 1 × 19 Strand Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 7/8" | 1" | 13/16" | 1 | Cast | Not Rated | 80% of the Rope's Capacity | __ | 0000000 | 0000 |

| 1/4" | 2 | 4 3/4" | 1 × 19 Strand Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 1 1/8" | 1 3/8" | 7/8" | 1 | Cast | 8 | 80% of the Rope's Capacity | __ | 0000000 | 00000 |

| 5/16" | 2 | 5 1/4" | 1 × 19 Strand Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 1 3/8" | 1 11/16" | 1 1/16" | 1 | Cast | 15 | 80% of the Rope's Capacity | __ | 0000000 | 00000 |

| 3/8" | 2 | 6 1/2" | 1 × 19 Strand Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 1 3/4" | 2 1/16" | 1 3/8" | 1 | Cast | 30 | 80% of the Rope's Capacity | __ | 0000000 | 00000 |

| 7/16", 1/2" | 2 | 11 1/2" | 1 × 19 Strand Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 2" | 2 1/2" | 1 1/2" | 1 | Cast | 45 | 80% of the Rope's Capacity | __ | 0000000 | 00000 |

| 1/2", 9/16" | 3 | 12" | 1 × 19 Strand Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 2 1/16" | 2 11/16" | 1 3/4" | 1 | Cast | 95 | 80% of the Rope's Capacity | __ | 0000000 | 00000 |

| 5/8" | 3 | 12" | 1 × 19 Strand Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 2 3/8" | 3 1/8" | 1 7/8" | 1 | Cast | 95 | 80% of the Rope's Capacity | __ | 0000000 | 00000 |

| 3/4" | 4 | 18" | 1 × 19 Strand Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 2 7/16" | 3 1/8" | 2 1/16" | 1 | Cast | 130 | 80% of the Rope's Capacity | __ | 0000000 | 000000 |

Wire Rope Clamps with Thimbles—Not for Lifting

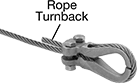

A clamp and thimble in one convenient fitting simplifies installation while providing support and fray protection to the wire rope loop. Use a torque wrench to tighten the clamp.

Warning: Test all assemblies for required strength before use. Do not use with coated rope unless the coating is removed.

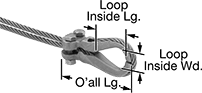

Loop | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Wire Rope Dia. | Rope Turnback | For Wire Rope Construction | Inside Lg. | Inside Wd. | Overall Lg. | Fabrication | Required Torque, ft.-lbs. | Capacity, lbs. | Each | |

Bronze | ||||||||||

| 1/8" | 3 1/4" | 6 × 7 Fiber Core 6 × 19 IWRC 6 × 19 Fiber Core 6 × 26 IWRC 6 × 37 IWRC | 15/16" | 9/16" | 2 1/2" | Cast | 8 | 300 | 0000000 | 000000 |

| 3/16" | 3 3/4" | 6 × 7 Fiber Core 6 × 19 IWRC 6 × 19 Fiber Core 6 × 26 IWRC 6 × 37 IWRC | 1 1/8" | 21/32" | 2 7/8" | Cast | 12 | 600 | 0000000 | 00000 |

| 1/4" | 4 3/4" | 6 × 7 Fiber Core 6 × 19 IWRC 6 × 19 Fiber Core 6 × 26 IWRC 6 × 37 IWRC | 1 9/16" | 7/8" | 3 3/4" | Cast | 19 | 1,000 | 0000000 | 00000 |

| 5/16" | 5 1/4" | 6 × 7 Fiber Core 6 × 19 IWRC 6 × 19 Fiber Core 6 × 26 IWRC 6 × 37 IWRC | 1 15/16" | 1 1/16" | 4 5/8" | Cast | 19 | 1,600 | 0000000 | 00000 |

Steel | ||||||||||

| 3/8" | 6 1/2" | 6 × 7 Fiber Core 6 × 19 IWRC 6 × 19 Fiber Core 6 × 26 IWRC 6 × 37 IWRC | 2 5/16" | 1 1/4" | 5 3/4" | Cast | 40 | 2,200 | 0000000 | 00000 |