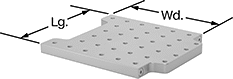

Fixture Plates

Lay the foundation for your fixturing setup. These plates have a grid with evenly spaced threaded holes to install angle brackets and other fixturing components. They’re often used to help secure workpieces for measuring and inspecting. Just like a battleship gameboard, the edges are labeled with letters and numbers, making it easy to identify holes. While these lightweight plates aren’t for machining, you can use them for light fabrication jobs, such as laser marking. All can be attached to your table with clamps (not included), making them easy to remove and swap.

Anodized aluminum plates are often used with coordinate measuring machines (CMMs) and optical comparators. The coating protects them from scratches and wear, even when you’re working with heavy parts.

Holes | ||||||||

|---|---|---|---|---|---|---|---|---|

| Lg. | Wd. | Thick. | Parallel Tolerance | No. of | Ctr.-to-Ctr. | Material | Each | |

1/4"-20 Hole Thread Size | ||||||||

| 18" | 18" | 1/2" | 0.01" | 1,156 | 1/2" | Anodized Aluminum | 0000000 | 000000000 |

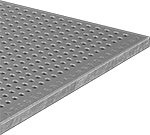

Quick-Change Fixture Plates

Snap these magnetic plates in and out of the mounting rail as swappable stages for measuring and inspecting parts. Unlike standard fixture plates that you need to bolt or clamp down, these quickly attach and release, creating a hub of plates that are locked and loaded. As your coordinate measuring machine (CMM) works in the background, position your next workpiece on another plate so it’s ready to switch out for the next run. If you need more room to inspect parts, combine plates in a chain to extend your surface. While they’re not sturdy enough for use in machining, you can use them for light fabrication work, such as laser engraving.

When docked on a rail, the strong magnets in these plates hold them still. The lightweight aluminum makes them easy to lift and swap, and an anodized coating protects them from scratches and wear, even if you’re working with heavy parts.

Fixture plates hold components such as towers, clamps, and standoffs in the evenly spaced holes to raise and position parts.

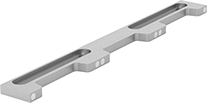

Mounting rails are the home base for your magnetic fixture plates, corner plates, and plates for calibration spheres. Bolt them to your table to secure the dock for your quick-change system hub. Quick-change plate adapters allow you to convert a standard fixture plate into a quick-change fixture plate compatible with the mounting rail.

Magnetic Mount | Bolt-On Mount | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Lg. | Wd. | Thick. | Max. Magnetic Pull, lbs. | For Max. No. of Mounting Edges | Mounting Fasteners Included | No. of Mounting Slots | Mounting Slot Lg. | Mounting Slot Wd. | Material | Each | |

For Inch Plates | |||||||||||

| 18" | 2" | 1/2" | 3.5 | 3 | No | 2 | 5 7/16" | 1/2" | Anodized Aluminum | 0000000 | 0000000 |