Filter by

Material

System of Measurement

Hole Thread Size

Length

Finish

DFARS Specialty Metals

Export Control Classification Number (ECCN)

REACH

RoHS

Mounting Fastener Thread Size

Maximum Magnetic Pull

Number of Mounting Holes

Mounting Hole Center-to-Center

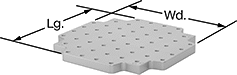

Fixture Plates

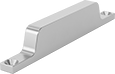

Quick-Change Adapters

Magnetic Mount | Bolt-On Mount | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Wd. | Thk. | Max. Magnetic Pull, lbf | No. of Mounting Edges | Mounting Fasteners Included | No. of Mounting Holes | For Mounting Fastener Thread Size | Mounting Hole Ctr.-to-Ctr. | Material | Each | |||

| 6" | 1" | 1/2" | 3.5 | 1 | Yes | 2 | 10-32 | 5 1/2" | Anodized Aluminum | 0000000 | 0000000 | ||

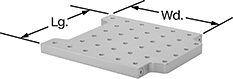

Quick-Change Fixture Plates

Fixture Plates

|  |

1 Mounting Edge | 4 Mounting Edges |

Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Wd. | Thk. | Parallel Tolerance | No. of | Ctr.-to-Ctr. | Max. Magnetic Pull, lbf | Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 Mounting Edge—1/4"-20 Hole Thread Size | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 6" | 1/2" | 0.005" | 36 | 1" | 3.5 | Anodized Aluminum | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 12" | 1/2" | 0.005" | 72 | 1" | 3.5 | Anodized Aluminum | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 12" | 1/2" | 0.005" | 237 | 1/2" | 3.5 | Anodized Aluminum | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 18" | 1/2" | 0.005" | 108 | 1" | 3.5 | Anodized Aluminum | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

4 Mounting Edges—1/4"-20 Hole Thread Size | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 6" | 1/2" | 0.005" | 52 | 1" | 3.5 | Anodized Aluminum | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

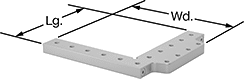

Corner Plates

Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Wd. | Thk. | Parallel Tolerance | No. of | Ctr.-to-Ctr. | Max. Magnetic Pull, lbf | Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 Mounting Edge—1/4"-20 Hole Thread Size | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 6" | 1/2" | 0.005" | 15 | 1" | 3.5 | Anodized Aluminum | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||