Filter by

Environment

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Material

REACH

Machine Tool Indicators

Find the exact edge of a workpiece without math or guesswork to quickly align your machining setup. Unlike most edge finders, these indicators don't require you to monitor the contact point's position and then add or subtract its diameter. When the display shows zero, that's your edge. These indicators move along three axes, so you can also use them to measure part dimensions, check surface flatness, and locate the centers of holes. The display swivels, eliminating the need to lean into your machine or set up mirrors to measure the back of your part.

Insert these indicators into your CNC or manual milling machine, adjust the set screws at the top to calibrate them, and they're ready to go. To stop the indicator from breaking, the contact point has a ceramic body that fractures if it collides with your part. Just screw on a new contact point to replace it without having to re-calibrate.

Dial Display

|

Measuring | Dial | Mounting Shank | Contact Point | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Distance | Increments | Accuracy | Dia. | Reading | Dia. | Lg. | Dia. | Lg. | Mounting Thread Size | Material | Overall Lg. | Enclosure Rating | Each | ||

| 0" to 0.15" | 0.0005" | -0.0005" to 0.0005" | 2.6" | 0-50 | 3/4" | 2" | 0.2" | 1" | M3 × 0.5 mm | Stainless Steel | 6.37" | IP67 | 2350N11 | 0000000 | |

| 0" to 0.15" | 0.001" | -0.001" to 0.001" | 1.92" | 0-50 | 0.39" | 1" | 0.2" | 1" | M3 × 0.5 mm | Stainless Steel | 4.756" | IP67 | 2350N13 | 000000 | |

LCD Digital Display

|

These indicators have zero-position memory, also called absolute (ABS) positioning, which saves their position even when turned off. Press the button to set them to zero and start measuring at any point. The large numbers on the display are easy to read from far away, such as when mounted at the center of a large CNC machine.

Machine Tool Indicators | Replacement Batteries | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Measuring | Mounting Shank | Contact Point | ||||||||||||||||

Distance | Increments | Accuracy | Dial Dia. | Dia. | Lg. | Dia. | Lg. | Mounting Thread Size | Material | Overall Lg. | Batteries Included | Enclosure Rating | Each | Pkg. Qty. | Pkg. | |||

| 0" to 0.15" | 0.00005" | -0.0002" to 0.0002" | 2.6" | 3/4" | 2" | 0.2" | 1" | M3 × 0.5 mm | Stainless Steel | 6.37" | Yes | IP64 | 2350N12 | 000000000 | 1 | 7701K34 | 00000 | |

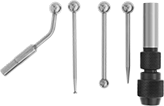

Starrett Swiveling Machine Tool Indicator Tip Sets

|

Determine tool spindle position in relation to work surface, layout lines, holes, and slots. Also known as wiggler sets. Attachments are interchangeable.

Includes | Material | Each | ||

|---|---|---|---|---|

| 0.10" Diameter Disc Contact, 0.25" Ball Contact, Chuck, Needle Point, Offset Indicator Holder | Steel | 8632A72 | 000000 |