Filter by

Mounting Position

System of Measurement

Sold As

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Number of Mounting Slots

Fitting Connection

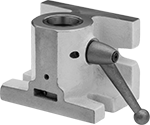

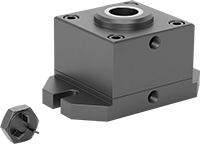

Collet Fixtures

Lever Actuator

Mounting Slots | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Collet Type | For Max. Workpiece Dia. | Through-Hole Dia. | Lg. | Wd. | Ht. | Material | No. of | Wd. | Mounting Position | Power Source | Each | ||

| 5C | 1 1/16" | 1 1/16" | 3 3/4" | 5" | 4" | Enamel-Coated Cast Iron | 4 | 11/16" | Horizontal, Vertical | Manual | 0000000 | 0000000 | |

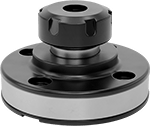

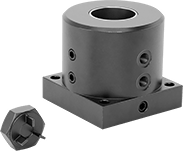

Collet Nut Actuator

Mounting Holes | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Collet Type | For Max. Workpiece Dia. | Through-Hole Dia. | Dia. | Ht. | Material | No. of | Dia. | Bolt Circle Dia. | Mounting Position | Power Source | Each | ||

| ER-16 | 3/8" | 7/16" | 2 3/4" | 2 1/2" | Black-Oxide Steel | 4 | 1/4" | 2 1/8" | Horizontal, Vertical | Manual | 0000000 | 0000000 | |

| ER-20 | 1/2" | 7/16" | 2 3/4" | 2 1/2" | Black-Oxide Steel | 4 | 1/4" | 2 1/8" | Horizontal, Vertical | Manual | 0000000 | 000000 | |

| ER-25 | 5/8" | 7/16" | 2 3/4" | 2 1/2" | Black-Oxide Steel | 4 | 1/4" | 2 1/8" | Horizontal, Vertical | Manual | 0000000 | 000000 | |

| ER-25 | 5/8" | 11/16" | 5" | 3" | Black-Oxide Steel | 4 | 7/16" | 4" | Horizontal, Vertical | Manual | 0000000 | 000000 | |

| ER-32 | 13/16" | 11/16" | 5" | 3" | Black-Oxide Steel | 4 | 7/16" | 4" | Horizontal, Vertical | Manual | 0000000 | 000000 | |

| ER-40 | 1" | 11/16" | 5" | 3" | Black-Oxide Steel | 4 | 7/16" | 4" | Horizontal, Vertical | Manual | 0000000 | 000000 | |

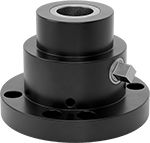

Square Drive Actuator

Mounting Holes | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Collet Type | For Max. Workpiece Dia. | Through-Hole Dia. | Dia. | Ht. | Material | No. of | Dia. | Bolt Circle Dia. | Mounting Position | Power Source | Includes | Each | ||

| 5C | 1 1/16" | 1 3/16" | 5" | 3 1/2" | Black-Oxide Steel | 6 | 3/8" | 4 1/8" | Horizontal, Vertical | Manual | Socket Wrench | 0000000 | 000000000 | |

| 16C | 1 5/8" | 1 13/16" | 5" | 4 1/2" | Black-Oxide Steel | 6 | 3/8" | 4 1/8" | Horizontal, Vertical | Manual | Socket Wrench | 0000000 | 00000000 | |

| 3J | 1 3/4" | 1 15/16" | 5" | 4" | Black-Oxide Steel | 6 | 3/8" | 4 1/8" | Horizontal, Vertical | Manual | Socket Wrench | 0000000 | 00000000 | |

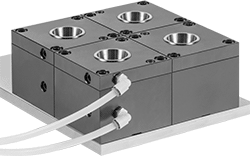

Air-Operated Collet Fixtures

Mounting Holes | Air Inlet | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Sold As | For Collet Type | For Max. Workpiece Dia. | Dia. | Ht. | Max. Clamping Pressure, psi | Max. Air Pressure, psi | Material | No. of | Dia. | Mounting Position | No. of Air Ports | Connection Port | Pipe Size | Thread Type | Gender | Power Source | Includes | Each | ||

| Individual | 5C | 1 1/16" | 5 1/2" | 3 1/4" | 1,125 | 150 | Aluminum | 4 | 3/8" | Vertical | 2 | Hose | 1/4 | NPS | Male | Air | — | 0000000 | 0000000 | |

| Kit | 5C | 1 1/16" | 5 1/2" | 3 1/4" | 1,125 | 150 | Aluminum | 4 | 3/8" | Vertical | 2 | Hose | 1/4 | NPS | Male | Air | Air-Operated Fixture, Four-Way Foot-Operated Air Valve, Three 6-ft. Long Air Hoses | 0000000 | 000000 | |

High-Density Air/Hydraulic-Operated Collet Fixtures

Collet Fixtures | Connectors | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Pressure, psi | Max. Clamping Force, psi | Mounting Holes | Mounting Slots | Port | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Collet Type | For No. of Collets | For Max. Workpiece Dia. | Through-Hole Dia. | Lg. | Wd. | Ht. | Air | Hydraulic | Air-Powered | Hydraulic-Powered | Material | No. of | Thread Size | Dia. | Lg. | Wd. | No. of Ports | Pipe Size | Thread Type | Thread Gender | Includes | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Collet Fixtures with Locking Screw | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pull Back | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5C | 1 | 1 1/16" | 1 3/16" | 4" | 4" | 3 1/2" | 150 | — | 1,125 | — | Aluminum | 4 | 3/8"-24 | — | — | — | 2 | 1/4 | NPT | Female | Collet Wrench | 0000000 | 0000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pull Back—Flange Mount | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5C | 1 | 1 1/16" | 1 3/16" | 6 1/2" | 4" | 3 1/2" | 150 | — | 1,125 | — | Aluminum | 4 | 3/8"-24 | — | 1" | 1/2" | 2 | 1/4 | NPT | Female | Collet Wrench | 0000000 | 000000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Collet Fixtures with Top-Locking Screw | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fixed Length | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1C | 1 | 1/4" | 5/16" | 1 3/4" | 1 3/4" | 1 7/16" | 250 | 750 | 180 | 545 | Aluminum | 4 | 10-24 | — | — | — | 2 | 1/8 | NPT | Female | Collet Wrench | 0000000 | 000000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3C | 1 | 1/2" | 5/8" | 2 1/2" | 2 1/2" | 2 3/4" | 250 | 750 | 300 | 900 | Aluminum | 4 | 1/4"-20 | — | — | — | 2 | 1/8 | NPT | Female | Collet Wrench | 0000000 | 000000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5C | 1 | 1 1/16" | 1 3/16" | 4" | 4" | 3 5/16" | 150 | 400 | 3,825 | 19,125 | Aluminum | 4 | 3/8"-16 | — | — | — | 2 | 1/4 | NPT | Female | Collet Wrench | 0000000 | 000000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5C | 3 | 1 1/16" | 1 3/16" | 8" | 3 1/2" | 3 5/16" | — | 5,000 | — | 5,500 | Aluminum | 4 | 5/16"-18 | — | — | — | 2 | 7/16 | UNF | Female | Collet Wrench | 0000000 | 00000000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16C | 1 | 1 5/8" | 1 7/8" | 4" | 4" | 4 1/4" | 250 | 2,000 | 1,450 | 11,600 | Aluminum | 4 | 3/8"-16 | — | — | — | 2 | 1/4 | NPT | Female | Collet Wrench | 0000000 | 000000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fixed Length—Flange Mount | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3J | 1 | 1 3/4" | 1 15/16" | 4" | 4" | 3 3/4" | — | 5,000 | — | 9,500 | Steel | 4 | — | 3/8" | — | — | 2 | 7/16 | UNF | Female | Collet Wrench | 0000000 | 00000000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||