Filter by

Collet Size

System of Measurement

Collet Type

Face Type

Total Indicated Runout (TIR) Accuracy

Body Diameter

Material

For Holding

DFARS Specialty Metals

Export Control Classification Number (ECCN)

External Thread Size

For Use With

Internal Thread Size

Overall Length

REACH

RoHS

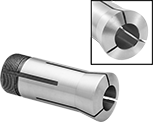

5C Collets

Round

These collets tightly grip workpieces when installed into a 5C collet chuck or holder. They provide a stronger hold on small workpieces than a standard lathe chuck.

| Collet Size | TIR (Total Indicated Runout) Accuracy | Workpiece Dia. Tolerance | Body Dia. | Overall Lg. | Internal Thread Size | External Thread Size | Material | Each | |

Round | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 25mm | 0.0015" | -0.004" to 0" | 1 1/4" | 3.27" | 1.041"-24 | 1.238"-20 | Steel | 00000000 | 000000 |