Filter by

Speed @ Continuous Operating Torque

Maximum Rotation Speed

Continuous Operating Torque

Starting Torque

Direction of Operation

Mounting Position

Enclosure Material

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Gear Material

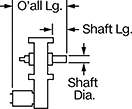

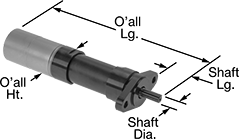

Compact DC Gearmotors

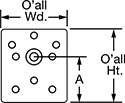

Square Face

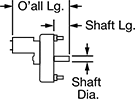

Overall | Shaft | Insulation | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Speed @ Continuous Operating Torque | Power, hp | Full Load Current, amp | Lg. | Wd. | Ht. | Bearing Type | Dia. | Lg. | Ctr.-to-Base Lg. | Class | Max. Temp., ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12V DC | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.2 rpm @ 800 in·ozf | 0.001 | 0.5 | 3 1/2" | 2 3/4" | 3" | Plain | 5/16" | 1" | 1.43" | B | 266 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 rpm @ 640 in·ozf | 0.0025 | 0.7 | 3 1/4" | 2 3/4" | 3" | Plain | 5/16" | 1" | 1.43" | B | 266 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 rpm @ 640 in·ozf | 0.005 | 0.7 | 4" | 2 3/4" | 3" | Plain | 5/16" | 1" | 1.43" | B | 266 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 rpm @ 640 in·ozf | 0.0077 | 1.3 | 3 1/2" | 2 3/4" | 3" | Plain | 5/16" | 1" | 1.43" | B | 266 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 rpm @ 400 in·ozf | 0.0067 | 1.4 | 3 1/2" | 2 3/4" | 3" | Plain | 5/16" | 1" | 1.43" | B | 266 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 26 rpm @ 320 in·ozf | 0.008 | 1.3 | 3 1/2" | 2 3/4" | 3" | Plain | 5/16" | 1" | 1.43" | B | 266 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 47 rpm @ 160 in·ozf | 0.008 | 1.2 | 3 1/2" | 2 3/4" | 3" | Plain | 5/16" | 1" | 2.08" | B | 266 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

24V DC | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.2 rpm @ 800 in·ozf | 0.001 | 0.1 | 3 1/4" | 2 3/4" | 3" | Plain | 5/16" | 1" | 1.43" | B | 266 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 rpm @ 800 in·ozf | 0.0033 | 0.4 | 3 1/4" | 2 3/4" | 3" | Plain | 5/16" | 1" | 1.43" | B | 266 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 rpm @ 544 in·ozf | 0.0043 | 0.5 | 3 1/2" | 2 3/4" | 3" | Plain | 5/16" | 1" | 1.43" | B | 266 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 rpm @ 384 in·ozf | 0.0045 | 0.4 | 3 1/2" | 2 3/4" | 3" | Plain | 5/16" | 1" | 1.43" | B | 266 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 rpm @ 272 in·ozf | 0.0045 | 0.5 | 3 1/2" | 2 3/4" | 3" | Plain | 5/16" | 1" | 1.43" | B | 266 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 22 rpm @ 800 in·ozf | 0.02 | 1.1 | 4" | 2 3/4" | 3" | Plain | 5/16" | 1" | 1.43" | B | 266 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 42 rpm @ 448 in·ozf | 0.02 | 1.1 | 4" | 2 3/4" | 3" | Plain | 5/16" | 1" | 2.08" | B | 266 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 62 rpm @ 240 in·ozf | 0.02 | 0.9 | 4" | 2 3/4" | 3" | Plain | 5/16" | 1" | 1.38" | B | 266 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 70 rpm @ 160 in·ozf | 0.01 | 0.7 | 3 3/4" | 2 3/4" | 3" | Plain | 5/16" | 1" | 1.38" | B | 266 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 80 rpm @ 160 in·ozf | 0.01 | 0.9 | 3 1/2" | 2 3/4" | 3" | Plain | 5/16" | 1" | 1.38" | B | 266 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 89 rpm @ 80 in·ozf | 0.01 | 0.3 | 3 1/2" | 2 3/4" | 3" | Plain | 5/16" | 1" | 1.38" | B | 266 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 rpm @ 80 in·ozf | 0.01 | 0.5 | 3 1/2" | 2 3/4" | 3" | Plain | 5/16" | 1" | 1.38" | B | 266 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

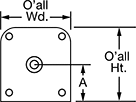

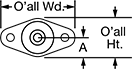

Rectangular Face

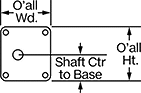

Overall | Shaft | Insulation | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Speed @ Continuous Operating Torque | Power, hp | Full Load Current, amp | Lg. | Wd. | Ht. | Bearing Type | Dia. | Lg. | Ctr.-to-Base Lg. | Class | Max. Temp., ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12V DC | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.4 rpm @ 2,400 in·ozf | 0.002 | 0.3 | 3 3/4" | 2 3/4" | 4 5/8" | Plain | 1/2" | 7/8" | 1.38" | B | 266 | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 rpm @ 1,920 in·ozf | 0.01 | 1.4 | 5" | 2 3/4" | 4 5/8" | Plain | 1/2" | 7/8" | 1.38" | B | 266 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9 rpm @ 1,600 in·ozf | 0.02 | 2.6 | 5" | 2 3/4" | 4 5/8" | Plain | 1/2" | 7/8" | 1.38" | B | 266 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18 rpm @ 880 in·ozf | 0.02 | 2.4 | 4 3/4" | 2 3/4" | 4 5/8" | Plain | 1/2" | 1 1/8" | 1.38" | B | 266 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24 rpm @ 688 in·ozf | 0.02 | 2.8 | 4 1/2" | 2 3/4" | 4 5/8" | Plain | 1/2" | 7/8" | 1.38" | B | 266 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

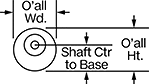

Round Face

|  |  |

Overall | Shaft | Insulation | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Speed @ Continuous Operating Torque | Power, hp | Full Load Current, amp | Lg. | Wd. | Ht. | Bearing Type | Dia. | Lg. | Ctr.-to-Base Lg. | Class | Max. Temp., ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12V DC | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 rpm @ 175 in·ozf | 0.0001 | 0.2 | 4 1/4" | 2" | 2" | Plain | 1/4" | 3/4" | 1.33" | F | 311 | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 rpm @ 175 in·ozf | 0.0004 | 0.4 | 4 1/4" | 2" | 2" | Plain | 1/4" | 3/4" | 1.33" | F | 311 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 rpm @ 140 in·ozf | 0.001 | 0.7 | 4 1/4" | 2" | 2" | Plain | 1/4" | 3/4" | 1.33" | F | 311 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 rpm @ 47 in·ozf | 0.001 | 0.7 | 4 1/4" | 2" | 2" | Plain | 1/4" | 3/4" | 1.33" | F | 311 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 83 rpm @ 16 in·ozf | 0.0012 | 0.7 | 4 1/4" | 2" | 2" | Plain | 1/4" | 3/4" | 1.33" | F | 311 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 161 rpm @ 374 in·ozf | 0.0714 | 6.4 | 6 1/4" | 2 1/8" | 2 3/4" | Ball | 1/4" | 3/4" | 1" | F | 311 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 536 rpm @ 124 in·ozf | 0.0769 | 6.4 | 6 1/4" | 2 1/8" | 2 3/4" | Ball | 1/4" | 3/4" | 1" | F | 311 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

19.1V DC | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 21 rpm @ 100 in·ozf | 0.0021 | 0.5 | 3 3/4" | 1 3/8" | 1 3/8" | Plain | 0.19" | 3/4" | 0.95" | F | 311 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 65 rpm @ 46 in·ozf | 0.0032 | 0.6 | 3 3/4" | 1 3/8" | 1 3/8" | Plain | 0.19" | 3/4" | 0.95" | F | 311 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 202 rpm @ 16 in·ozf | 0.0036 | 0.6 | 3 3/4" | 1 3/8" | 1 3/8" | Plain | 0.19" | 3/4" | 0.95" | F | 311 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 625 rpm @ 6 in·ozf | 0.004 | 0.6 | 3 3/4" | 1 3/8" | 1 3/8" | Plain | 0.19" | 3/4" | 0.95" | F | 311 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

24V DC | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 161 rpm @ 374 in·ozf | 0.0714 | 3.2 | 6 1/4" | 2 1/8" | 2 3/4" | Ball | 1/4" | 3/4" | 1" | F | 311 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 536 rpm @ 124 in·ozf | 0.0769 | 3.2 | 6 1/4" | 2 1/8" | 2 3/4" | Ball | 1/4" | 3/4" | 1" | F | 311 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

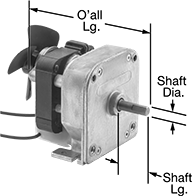

Base/Face-Mount Compact AC Gearmotors

Gearmotors | Replacement Fan Blades for Counterclockwise Shaft Rotation | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Shaft | Insulation | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Max. Rotation Speed, rpm | Torque @ Max. Speed, in·lbf | Power, hp | Radial Load Cap., lb. | Full Load Current, amp | Motor Enclosure Type | Lg. | Wd. | Ht. | Dia. | Lg. | Ctr.-to-Base Lg. | Class | Max. Temp., ° F | Certification | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

115V AC, Single Phase | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 50 | 1/300 | 25 | 0.4 | Open | 4 1/2" | 3 1/4" | 3 1/4" | 0.31" | 1" | 1 5/8" | B | 266 | UL Recognized Component, CSA Certified | 0000000 | 000000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 50 | 1/300 | 25 | 0.4 | Open | 4 1/2" | 3 1/4" | 3 1/4" | 0.31" | 1" | 1 5/8" | B | 266 | UL Recognized Component, CSA Certified | 0000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 40 | 1/300 | 25 | 0.4 | Open | 4 1/2" | 3 1/4" | 3 1/4" | 0.31" | 1" | 1 5/8" | B | 266 | UL Recognized Component, CSA Certified | 0000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 40 | 1/150 | 25 | 1 | Open | 4 3/4" | 3 1/4" | 3 1/4" | 0.31" | 1" | 1 5/8" | B | 266 | UL Recognized Component, CSA Certified | 0000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 20 | 1/150 | 25 | 1 | Open | 4 3/4" | 3 1/4" | 3 1/4" | 0.31" | 1" | 1 5/8" | B | 266 | UL Recognized Component, CSA Certified | 0000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | 15 | 1/120 | 25 | 1.2 | Open | 5" | 3 1/4" | 3 1/4" | 0.31" | 1" | 1 5/8" | B | 266 | UL Recognized Component, CSA Certified | 0000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | 15 | 1/80 | 25 | 1.6 | Open | 5 1/4" | 3 1/4" | 3 1/4" | 0.31" | 1" | 1 5/8" | B | 266 | UL Recognized Component, CSA Certified | 0000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 75 | 10 | 1/80 | 25 | 1.6 | Open | 5 1/4" | 3 1/4" | 3 1/4" | 0.31" | 1" | 1 5/8" | B | 266 | UL Recognized Component, CSA Certified | 0000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | 7 | 1/80 | 25 | 1.6 | Open | 5 1/4" | 3 1/4" | 3 1/4" | 0.31" | 1" | 1 5/8" | B | 266 | UL Recognized Component, CSA Certified | 0000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 125 | 6 | 1/80 | 25 | 1.6 | Open | 5 1/4" | 3 1/4" | 3 1/4" | 0.31" | 1" | 1 5/8" | B | 266 | UL Recognized Component, CSA Certified | 0000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 150 | 5 | 1/80 | 25 | 1.6 | Open | 5 1/4" | 3 1/4" | 3 1/4" | 0.31" | 1" | 1 5/8" | B | 266 | UL Recognized Component, CSA Certified | 0000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 200 | 4 | 1/80 | 25 | 1.6 | Open | 5 1/4" | 3 1/4" | 3 1/4" | 0.31" | 1" | 1 5/8" | B | 266 | UL Recognized Component, CSA Certified | 0000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Compact Air-Powered Gearmotors

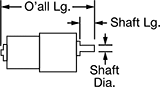

Face Mount

|  |  |

Push-to-Connect Fitting Connection | Threaded Fitting Connection |

@ 90 psi | Overall | Shaft | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Power, hp | Maximum Speed, rpm | Starting Torque, in·lbf | Max. Pressure, psi | Air Consumption @ 90 psi, ft³/min | Noise Level | Lg. | Wd. | Ht. | Dia. | Lg. | Center to Base (A) | Type | Direction of Operation | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Push-to-Connect Inlet for 1/4" OD Tubes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.027 | 25 | 67.5 | 150 | 6 | Not Rated | 6 3/4" | 1 1/2" | 3/4" | 1/4" | 0.437" | 0.38" | D-Profile | Clockwise, Counterclockwise | 000000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.099 | 100 | 62.5 | 150 | 6 | Not Rated | 6 1/4" | 1 1/2" | 3/4" | 1/4" | 0.437" | 0.38" | D-Profile | Clockwise, Counterclockwise | 000000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.107 | 200 | 33.8 | 150 | 6 | Not Rated | 5 1/2" | 1 1/2" | 3/4" | 1/4" | 0.437" | 0.38" | D-Profile | Clockwise, Counterclockwise | 000000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.127 | 400 | 20 | 150 | 6 | Not Rated | 5 1/2" | 1 1/2" | 3/4" | 1/4" | 0.437" | 0.38" | D-Profile | Clockwise, Counterclockwise | 000000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.137 | 6,300 | 1.4 | 150 | 6 | Not Rated | 4 1/4" | 1 1/2" | 3/4" | 1/4" | 0.437" | 0.38" | D-Profile | Clockwise, Counterclockwise | 000000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.156 | 1,575 | 6.3 | 150 | 6 | Not Rated | 5" | 1 1/2" | 3/4" | 1/4" | 0.437" | 0.38" | D-Profile | Clockwise, Counterclockwise | 000000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4 NPT Female Threaded Inlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.31 | 85 | 396 | 90 | 17.5 | Not Rated | 8 3/4" | 3 1/4" | 1 3/4" | 3/8" | 1" | 0.88" | Keyed | Clockwise, Counterclockwise | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.31 | 169 | 247.2 | 90 | 17.5 | Not Rated | 8 3/4" | 3 1/4" | 1 3/4" | 3/8" | 1" | 0.88" | Keyed | Clockwise, Counterclockwise | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.31 | 280 | 147.6 | 90 | 17.5 | Not Rated | 8 3/4" | 3 1/4" | 1 3/4" | 3/8" | 1" | 0.88" | Keyed | Clockwise, Counterclockwise | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.34 | 450 | 106.2 | 90 | 18 | Not Rated | 8" | 3 1/4" | 1 3/4" | 3/8" | 1" | 0.88" | Keyed | Clockwise, Counterclockwise | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

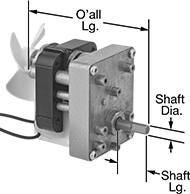

Face-Mount Compact AC Gearmotors

Gearmotors | Replacement Fan Blades for Counterclockwise Shaft Rotation | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

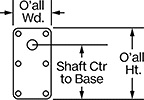

Overall | Shaft | Insulation | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Max. Rotation Speed, rpm | Torque @ Max. Speed, in·lbf | Power, hp | Radial Load Cap., lb. | Full Load Current, amp | Motor Enclosure Type | Lg. | Wd. | Ht. | Dia. | Lg. | Ctr.-to-Base Lg. | Class | Max. Temp., ° F | Certification | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

115V AC, Single Phase | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 50 | 1/300 | 25 | 0.4 | Open | 4" | 2 1/2" | 3" | 0.31" | 1" | 2.12" | B | 266 | UL Recognized Component, CSA Certified | 0000000 | 000000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 50 | 1/300 | 25 | 0.4 | Open | 4" | 2 1/2" | 3" | 0.31" | 1" | 2.12" | B | 266 | UL Recognized Component, CSA Certified | 0000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 40 | 1/150 | 25 | 1 | Open | 4 1/2" | 2 1/2" | 3" | 0.31" | 1" | 2.12" | B | 266 | UL Recognized Component, CSA Certified | 0000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 25 | 1/150 | 25 | 1 | Open | 4 1/2" | 2 1/2" | 3" | 0.31" | 1" | 2.12" | B | 266 | UL Recognized Component, CSA Certified | 0000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | 20 | 1/120 | 25 | 1.2 | Open | 4 3/4" | 2 1/2" | 3" | 0.31" | 1" | 2.12" | B | 266 | UL Recognized Component, CSA Certified | 0000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | 15 | 1/80 | 25 | 1.6 | Open | 5" | 2 1/2" | 3" | 0.31" | 1" | 2.12" | B | 266 | UL Recognized Component, CSA Certified | 0000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 75 | 15 | 1/80 | 25 | 1.6 | Open | 5" | 2 1/2" | 3" | 0.31" | 1" | 2.12" | B | 266 | UL Recognized Component, CSA Certified | 0000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | 7 | 1/80 | 25 | 1.6 | Open | 5" | 2 1/2" | 3" | 0.31" | 1" | 2.12" | B | 266 | UL Recognized Component, CSA Certified | 0000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 125 | 6 | 1/80 | 25 | 1.6 | Open | 5" | 2 1/2" | 3" | 0.31" | 1" | 2.12" | B | 266 | UL Recognized Component, CSA Certified | 0000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 150 | 5 | 1/80 | 25 | 1.6 | Open | 5" | 2 1/2" | 3" | 0.31" | 1" | 2.12" | B | 266 | UL Recognized Component, CSA Certified | 0000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 200 | 4 | 1/80 | 25 | 1.6 | Open | 5" | 2 1/2" | 3" | 0.31" | 1" | 2.12" | B | 266 | UL Recognized Component, CSA Certified | 0000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

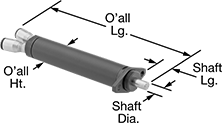

Stepper Gearmotors

|

Round Body |

Overall | Shaft | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Holding Torque, in·ozf | Max. Rotation Speed, rpm | Max. Current per Phase, amp | Full Step Increment | No. of Wire Leads | Lg. | Wd. | Ht. | Dia., mm | Lg., mm | Ctr.-to-Base Lg. | Type | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Round Body | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NEMA 5 Frame Size | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 27.8 | 680 | 0.56 | 1.875° | 4 | 2.6" | 0.5" | 0.5" | 3 | 8.5 | 0.26" | D-Profile | 0 to 120 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 27.8 | 680 | 0.9 | 1.875° | 4 | 2.6" | 0.5" | 0.5" | 3 | 8.5 | 0.26" | D-Profile | 0 to 120 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 41.7 | 40 | 0.56 | 0.11° | 4 | 2.9" | 0.5" | 0.5" | 3 | 8.5 | 0.26" | D-Profile | 0 to 120 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 41.7 | 40 | 0.9 | 0.11° | 4 | 2.9" | 0.5" | 0.5" | 3 | 8.5 | 0.26" | D-Profile | 0 to 120 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 41.7 | 165 | 0.56 | 0.45° | 4 | 2.8" | 0.5" | 0.5" | 3 | 8.5 | 0.26" | D-Profile | 0 to 120 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 41.7 | 165 | 0.9 | 0.45° | 4 | 2.8" | 0.5" | 0.5" | 3 | 8.5 | 0.26" | D-Profile | 0 to 120 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||