Balsa Wood Cores

Lighter in weight than any other wood, yet still strong, these balsa cores stiffen composite sandwiches without weighing them down. They resist damage from impact and repeated use. Because they don’t let heat or sound pass through quickly, these cores are good natural insulators. They also resist chemicals. All come from balsa trees grown in FSC (Forest Stewardship Council) certified forests. They cannot be sold to Canada due to import regulations.

Rigid cores are often used in panels for partitions, industrial tanks, and other stiff structures.

Flexible cores are best for forming complex shapes.

| Thickness | Width | Length | Compressive Strength, psi | Temperature Range, °F | Cannot Be Sold To | Each | |

| 1/4" | 24" | 48" | 1,500 | -100° to 325° | Canada | 00000000 | 000000 |

| 3/8" | 24" | 48" | 1,500 | -100° to 325° | Canada | 00000000 | 00000 |

| 1/2" | 24" | 48" | 1,500 | -100° to 325° | Canada | 00000000 | 00000 |

| 5/8" | 24" | 48" | 1,500 | -100° to 325° | Canada | 00000000 | 00000 |

| 3/4" | 24" | 48" | 1,500 | -100° to 325° | Canada | 00000000 | 00000 |

| 1" | 24" | 48" | 1,500 | -100° to 325° | Canada | 00000000 | 00000 |

| 2" | 24" | 48" | 1,500 | -100° to 325° | Canada | 00000000 | 00000 |

| Thickness | Width | Length | Compressive Strength, psi | Temperature Range, °F | Cannot Be Sold To | Each | |

| 1/4" | 24" | 48" | 1,500 | -100° to 325° | Canada | 00000000 | 000000 |

| 3/8" | 24" | 48" | 1,500 | -100° to 325° | Canada | 00000000 | 00000 |

| 1/2" | 24" | 48" | 1,500 | -100° to 325° | Canada | 00000000 | 00000 |

| 3/4" | 24" | 48" | 1,500 | -100° to 325° | Canada | 00000000 | 00000 |

| 1" | 24" | 48" | 1,500 | -100° to 325° | Canada | 00000000 | 00000 |

Stiff PVC Foam Cores

- Color: See table

- Maximum Temperature: 170° F

- Tensile Strength: See table

- For Use Outdoors: Yes

Add stiffness to composite sandwiches without adding a lot of weight. These cores are lighter in weight than balsa wood and aluminum honeycomb cores, but not as strong. Their cross-linked foam polymers, however, make them stronger and more durable than PET foam cores. All of these cores are moisture resistant and offer good sound insulation. Use them in composite layups, structural panels, partitions, and industrial tanks.

Scored cores have cuts in a grid pattern that make them easier to bend and form into complex shapes than plain cores.

| Thickness | Thickness Tolerance | Tensile Strength, psi | Tensile Strength Rating | Color | Each | |

Plain | ||||||

|---|---|---|---|---|---|---|

40" × 86" | ||||||

| 3/8" | -0.02" to 0.02" | 370 | Excellent | Green | 0000000 | 0000000 |

| 1/2" | -0.02" to 0.02" | 370 | Excellent | Green | 0000000 | 000000 |

| 5/8" | -0.02" to 0.02" | 370 | Excellent | Green | 0000000 | 000000 |

| 3/4" | -0.02" to 0.02" | 370 | Excellent | Green | 0000000 | 000000 |

| 1 1/4" | -0.02" to 0.02" | 370 | Excellent | Green | 0000000 | 000000 |

| 1 3/4" | -0.02" to 0.02" | 370 | Excellent | Green | 0000000 | 000000 |

45" × 96" | ||||||

| 1/2" | -0.02" to 0.02" | 300 | Excellent | Yellow | 0000000 | 000000 |

| 1" | -0.02" to 0.02" | 300 | Excellent | Yellow | 0000000 | 000000 |

| 1 1/4" | -0.02" to 0.02" | 300 | Excellent | Yellow | 0000000 | 000000 |

| 1 1/2" | -0.02" to 0.02" | 300 | Excellent | Yellow | 0000000 | 000000 |

| 2" | -0.02" to 0.02" | 300 | Excellent | Yellow | 0000000 | 000000 |

Scored | ||||||

45" × 48" | ||||||

| 3/8" | -0.02" to 0.02" | 300 | Excellent | Yellow | 0000000 | 000000 |

| 1/2" | -0.02" to 0.02" | 300 | Excellent | Yellow | 0000000 | 000000 |

| 3/4" | -0.02" to 0.02" | 300 | Excellent | Yellow | 0000000 | 000000 |

| 1" | -0.02" to 0.02" | 300 | Excellent | Yellow | 0000000 | 000000 |

Lightweight UV-Resistant PET Foam Cores

- Clarity: Opaque

- Maximum Temperature: 300° F

- Tensile Strength: See table

- Impact Strength: Not Rated

- Hardness Rating: Not Rated

- For Use Outdoors: Yes

When exposed to UV rays, these cores won’t become brittle or break down. Use them to add stiffness to composite sandwiches that may be used outdoors without adding a lot of weight. All of these cores are lighter in weight than PVC, balsa wood, and aluminum honeycomb cores, but not as strong. They’re also moisture resistant and recyclable. These cores are often used in composite layups, structural panels, partitions, and industrial tanks. You can even soften them with heat, place them into a mold, and then cool them to create a variety of different shapes. Those with a higher density are stiffer, stronger, and weigh more than those with a lower density.

| Thickness | Thickness Tolerance | Tensile Strength, psi | Tensile Strength Rating | Density, lbs./cu. in. | Each | |

Plain | ||||||

|---|---|---|---|---|---|---|

40" × 96" | ||||||

| 1/2" | -0.02" to 0.02" | 260 | Excellent | 0.002 | 0000000 | 000000 |

| 5/8" | -0.02" to 0.02" | 320 | Excellent | 0.003 | 0000000 | 000000 |

48" × 96" | ||||||

| 3/8" | -0.02" to 0.02" | 260 | Excellent | 0.002 | 0000000 | 000000 |

| 1/2" | -0.02" to 0.02" | 260 | Excellent | 0.002 | 0000000 | 000000 |

| 1/2" | -0.02" to 0.02" | 320 | Excellent | 0.003 | 0000000 | 000000 |

| 5/8" | -0.02" to 0.02" | 320 | Excellent | 0.003 | 0000000 | 000000 |

| 1" | -0.02" to 0.02" | 260 | Excellent | 0.002 | 0000000 | 000000 |

| 1" | -0.02" to 0.02" | 320 | Excellent | 0.003 | 0000000 | 000000 |

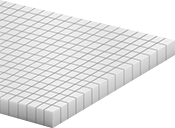

High-Temperature Acid-Resistant Silicon-Carbide Ceramic Foam

- Color: Gray

- Maximum Temperature: 3,000° F

- Compressive Strength: 200 psi

A silicon carbide coating over a carbon foam base combines the hardness, chemical resistance, and high temperatures silicon carbide is known for with the lightweight versaitility of foam. It’s often used for cores in composite layers and to filter molten metal and corrosive liquids.

The silicon carbide coating acts as a thermal conductor, transferring heat to quickly cool liquids that pass through. Known for its hardness, silicon carbide won’t break down from repeated abrasion. However, because it’s so hard, this material is more brittle than plain carbon foam and less impact resistant than balsa wood, PET, and PVC foam cores.

Acids and bases can’t penetrate the silicon carbide coating, even at high temperatures. Instead, contaminants stick to the surface, making it a great filter for corrosive liquids and environmental pollutants such as exhaust. If using this material as a filter, choose a foam with more pores per inch for a slower flow rate, and a foam with fewer pores per inch for a faster flow rate.

If you cut this material, the underlying carbon foam is exposed. Carbon foam does not have the temperature range and chemical resistance of its silicon carbide coating, so it will break down more quickly at exposed points.

3" × 3" | 6" × 6" | |||||

|---|---|---|---|---|---|---|

| Thickness | Thickness Tolerance | Pores Per Inch | Each | Each | ||

| 1/8" | -0.010" to 0.010" | 60 | 00000000 | 0000000 | 00000000 | 0000000 |

| 1/8" | -0.010" to 0.010" | 100 | 00000000 | 000000 | 00000000 | 000000 |

| 1/4" | -0.010" to 0.010" | 20 | 00000000 | 000000 | 00000000 | 00000000 |

| 1/4" | -0.010" to 0.010" | 60 | 00000000 | 000000 | 00000000 | 00000000 |

| 1/4" | -0.010" to 0.010" | 100 | 00000000 | 000000 | 00000000 | 00000000 |