Filter by

Overall Height

Mounting Hole Center-to-Center

DFARS Specialty Metals

Export Control Classification Number (ECCN)

For Use With

Manufacturer Model Number

REACH

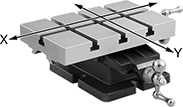

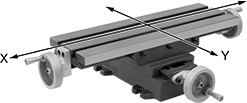

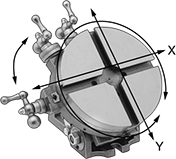

Precision-Adjust Cross-Slide Milling Tables

Table | Base | Max. Travel | X-Axis T-Slots | Y-Axis T-Slots | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Wd. | Lg. | Wd. | X-Axis | Y-Axis | X- and Y-Axis Adjustment Dial Graduations | Keyway Size | Overall Ht. | No. of | Wd. | Ctr.-to-Ctr. | No. of | Wd. | Ctr.-to-Ctr. | Flatness Tolerance | Material | Mounting Fasteners Included | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Standard-Table 50 lb. Load Capacity | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10" | 6" | 6 3/8" | 7 5/8" | 6" | 4" | 0.001" | 5/8" | 4 3/8" | 1 | 7/16" | — | 3 | 7/16" | 2 1/2" | 0.001" | Iron | No | 000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Standard-Table 150 lb. Load Capacity | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18 5/8" | 6" | 7 1/8" | 12" | 12" | 8" | 0.001" | — | 5 1/4" | 2 | 1/2" | 2 3/8" | — | — | — | 0.002" | Iron | No | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tilting-Table 50 lb. Load Capacity | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 6" | 5" | 9" | 8" | 4" | 0.001" | 5/8" | 4 5/8" | 1 | 7/16" | — | 3 | 7/16" | 3" | 0.001" | Iron | No | 000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

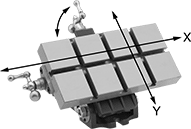

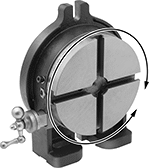

Precision-Adjust Cross-Slide Rotary Tables

Load Cap., lb. | Base | Max. Travel | T-Slots | Rotation Graduations | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Table Dia. | Horizontal | Vertical | Gear Ratio | Lg. | Wd. | X-Axis | Y-Axis | X- and Y-Axis Adjustment Dial Graduations | Overall Ht. | No. of | Wd. | Ctr. Bore Type | Ctr. Bore Dia. | Adjustment Dial | Table | Flatness Tolerance | Material | Mounting Fasteners Included | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Standard Table | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8" | 160 | 80 | 40:1 | 6 1/4" | 7 1/2" | 4" | 4" | 0.001" | 5 1/2" | 2 | 5/8" | Straight | 1 5/8" | 1/20° | 1° | 0.001" | Iron | No | 000000 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10" | 200 | 100 | 40:1 | 6 1/4" | 7 1/2" | 4" | 4" | 0.001" | 5 3/8" | 2 | 5/8" | Straight | 1 5/8" | 1/20° | 1° | 0.001" | Iron | No | 000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tilting Table | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8" | 160 | 80 | 40:1 | 5" | 9" | 4" | 4" | 0.001" | 5" | 2 | 5/8" | Straight | 1 5/8" | 1/20° | 1° | 0.001" | Iron | No | 000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10" | 200 | 100 | 40:1 | 5" | 9" | 4" | 4" | 0.001" | 5 3/4" | 2 | 5/8" | Straight | 1 5/8" | 1/20° | 1° | 0.001" | Iron | No | 000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

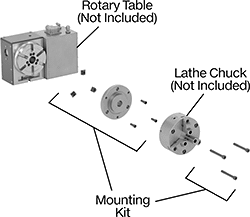

Rotary Table Mounting Kits for Lathe Chucks

|  |

For Lathe Chuck Dia. | For Mfr. Model No. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Haas | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | HRC160, HRT160, HRT160SP, HRT160SS, TR160, TR200Y, TRT160 | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8" | HRC210, HRT210, HRT210SP, HRT210SS, TR210, TRT210 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10" | HRC210, HRT210, HRT210SP, HRT210SS, TR210, TRT210 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | HRT310, HRT310SP, TR310 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Kitagawa | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8" | GT200, MR200 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10" | GT250, MR250 | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For DMG Mori | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8" | DDRT200 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10" | DDRT260 | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Hurco | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8" | H200 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10" | H250 | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

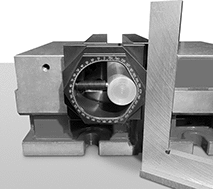

Rotary Angle Indexers

|  |  |

Indexer with Workpiece Shown in Vise | Indexer with Workpiece |

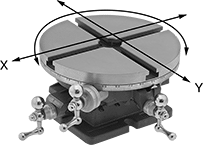

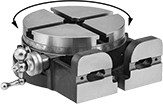

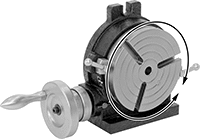

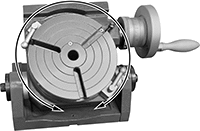

Precision-Adjust Rotary Tables

Rotary Tables | Tailstocks | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Load Cap., lb. | Base | T-Slots | Rotation Graduations | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Table Dia. | Horizontal | Vertical | Gear Ratio | Lg. | Wd. | Overall Ht. | No. of | Wd. | Ctr. Bore Type | Ctr. Bore Dia. | Machine Taper No. | Adjustment Dial | Table | Flatness Tolerance | Material | Mounting Fasteners Included | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Standard Table | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8" | 160 | 80 | 40:1 | 12" | 9 1/2" | 3 7/8" | 2 | 5/8" | Straight | 1 5/8" | — | 1/20° | 1° | 0.002" | Iron | No | 000000 | 000000000 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10" | 200 | 100 | 40:1 | 12" | 9 1/2" | 3 7/8" | 2 | 5/8" | Straight | 1 5/8" | — | 1/20° | 1° | 0.002" | Iron | No | 000000 | 00000000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Heavy Duty Table | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 90 | 40 | 90:1 | 8" | 6 5/16" | 3 1/8" | 3 | 3/8" | Morse Taper | — | Morse 2 | 1/10° | 1° | 0.0006" | Steel | No | 000000 | 000000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8" | 175 | 85 | 90:1 | 10 1/2" | 8 5/8" | 4 1/8" | 6 | 1/2" | Morse Taper | — | Morse 3 | 1/4° | 1° | 0.0006" | Steel | No | 000000 | 00000000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10" | 195 | 110 | 90:1 | 12 3/4" | 11" | 4 1/2" | 6 | 1/2" | Morse Taper | — | Morse 3 | 1/4° | 1° | 0.0006" | Steel | No | 000000 | 00000000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 265 | 130 | 90:1 | 15 5/16" | 13" | 5" | 6 | 5/8" | Morse Taper | — | Morse 3 | 1/10° | 1° | 0.0006" | Iron | No | 000000 | 00000000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16" | 310 | 130 | 90:1 | 20" | 17" | 5 1/8" | 6 | 5/8" | Morse Taper | — | Morse 4 | 1/10° | 1° | 0.0006" | Iron | No | 000000 | 00000000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Heavy Duty Tilting Table | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 75 | 35 | 90:1 | 9 3/4" | 6" | 8 1/2" | 3 | 3/8" | Morse Taper | — | Morse 3 | 1/4° | 1° | 0.0006" | Steel | No | 0000000 | 00000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

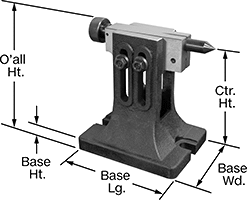

Tailstocks

Base | Mounting Slot | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ctr. Ht. | Lg. | Wd. | Ht. | Overall Ht. | No. of | Wd. | Mounting Fasteners Included | Material | Includes | Each | ||

| 3 1/4" to 4 1/4" | 5 3/8" | 3 3/4" | 4 1/8" | 4 1/4" | 2 | 5/8" | No | Cast Iron | Standard-Point Dead Center | 0000000 | 0000000 | |

| 4 1/2" to 5 3/4" | 6 1/8" | 4 3/8" | 5 7/8" | 5 3/4" | 2 | 5/8" | No | Cast Iron | Standard-Point Dead Center | 0000000 | 000000 | |

| 5 1/4" to 7 3/4" | 7 1/4" | 5 1/2" | 8 1/2" | 8" | 2 | 5/8" | No | Cast Iron | Standard-Point Dead Center | 0000000 | 000000 | |

| 7 1/2" to 10 1/4" | 7 7/8" | 5 3/4" | 10" | 10 1/4" | 2 | 5/8" | No | Cast Iron | Standard-Point Dead Center | 0000000 | 000000 | |