About Air Preparation

More

Desiccant Compressed Air Dryers

Once aftercoolers and separators have removed the bulk of the water, use these dryers to remove any remaining moisture in your air line. To reuse saturated desiccant, heat it in an oven at its reactivation temperature—you'll know it's dry when the color changes. Install these dryers after an oil filter to protect the desiccant.

Dryers with a clear bowl or a sight glass let you keep an eye on the contents inside. Dryers with a metal bowl are more durable than those with a plastic bowl, and they hold up to vapor better.

Dryers | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Size | O'all | Replacement Desiccants | |||||||||||

| Inlet | Outlet | Connections | Max. Flow Rate | Dew Point Temp., °F | Max. Temp., °F | Max. Pressure, psi | Housing Material | Ht. | Dia. | Each | Each | ||

Polycarbonate Plastic Bowl—Clear with Steel Guard | |||||||||||||

| 1/4 | 1/4 | NPT Female | 5 scfm @ 100 psi | -45° | 125° | 150 | Zinc | 6 1/2" | __ | 0000000 | 0000000 | 0000000 | 000000 |

| 1/4 | 1/4 | NPT Female | 10 scfm @ 100 psi | -45° | 125° | 150 | Zinc | 13 1/2" | 4 3/4" | 0000000 | 000000 | 0000000 | 000000 |

High-Pressure Desiccant Compressed Air Dryers

Get dry compressed air in high-pressure systems—these dryers have a maximum pressure rating of 300 psi. Once aftercoolers and separators have removed the bulk of the water, they remove any remaining moisture in your air line. Install after an oil filter to protect the desiccant. They have a sight glass so you can see inside the bowl to monitor contents.

Desiccant (sold separately) is required to remove moisture from air. To reuse saturated desiccant, heat it at its reactivation temperature until it returns to its dry color.

Disposable Desiccant Compressed Air Dryers

with Filters for Oil and Particle Removal

Use these dryers with filters to protect air-powered tools from water, oil, oil vapor, and particles, then throw them away when you're done. They have a polyurethane housing that has excellent resistance to synthetic compressor lubricants, solvents, acids, and chemicals. The bowl is clear so you can monitor the desiccant. When it becomes saturated, it changes color to indicate it should be replaced. Install in your air line just before the tool you want to protect.

Pipe Size | Overall | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Inlet | Outlet | Connections | Max. Flow Rate | Max. Pressure, psi | Max. Temp., °F | Dew Point Temp. Reduction Rate | Removes Particle Size Down To, microns | Dia. | Ht. | Desiccant Included | Each | |

Polyurethane Rubber Housing | ||||||||||||

Polyurethane Rubber Bowl—Clear | ||||||||||||

| 1/4 | 1/4 | NPT Female | 5 scfm @ 100 psi | 250 | 180° | 20% | 0.3 | 2 7/8" | 4 1/2" | Yes | 0000000 | 0000000 |

Disposable Desiccant Compressed Air Dryers with Filters for Particle Removal

Install these dryers just before air-powered tools as final protection from water and particles and throw them away when you’re done. They have a clear bowl so you can see inside to monitor the desiccant. When the desiccant becomes saturated, it changes color to indicate that the dryer should be changed.

Inlet | Outlet | Overall | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Connection | Pipe Size | Connection | Max. Flow Rate | Dew Point Temp., °F | Max. Pressure, psi | Max. Temp., °F | Removes Particle Size Down To, microns | Dia. | Ht. | Desiccant Included | Each | |

Polycarbonate Plastic Bowl—Clear | |||||||||||||

| 1/4 | NPT Female | 1/4 | NPT Male | 20 scfm @ 100 psi | -30° | 125 | 130° | 40 | 1 3/4" | 3 3/4" | Yes | 000000 | 000000 |

Maintenance-Free Membrane Compressed Air

Dryers with Filters for Oil and Particle Removal

Dry air without hassle—there’s no desiccant to change out with these dryers. They remove vapor from compressed air lines by collecting it in a membrane. A small stream is diverted from the incoming compressed air to release the collected vapor from the membrane. Use them in applications where water vapor can damage tools, such as painting and welding. All come with a built-in oil and particle filter to catch contaminants for a compact design. Install these air dryers after aftercoolers and separators.

Air Dryers | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Size | Overall | Replacement Oil Filter Elements | Replacement Particle Filter Elements | ||||||||||||||

| Inlet | Outlet | Connections | Max. Flow Rate | Dew Point Temp., °F | Max. Pressure, psi | Max. Temp., °F | Removes Particle Size Down To, microns | Removes Oil Content Down To, ppm | Housing Material | Dia. | Ht. | Each | Each | Each | |||

Polycarbonate Plastic/Zinc Bowl—Opaque with Sight Glass | |||||||||||||||||

| 1/4 | 1/4 | NPT Female | 0.25 scfm @ 100 psi | -40° | 150 | 120° | 0.01 | 0.008 | Aluminum, PVC, Vinyl, Zinc | 1" | 4 1/4" | 0000000 | 000000000 | 0000000 | 000000 | 0000000 | 000000 |

Aluminum/Zinc Bowl—Opaque with Sight Glass | |||||||||||||||||

| 1/4 | 1/4 | NPT Female | 0.8 scfm @ 100 psi | -40° | 150 | 120° | 0.01 | 0.008 | Aluminum, PVC, Vinyl, Zinc | 1 3/4" | 8 1/2" | 0000000 | 00000000 | 0000000 | 00000 | 0000000 | 00000 |

| 1/4 | 1/4 | NPT Female | 2 scfm @ 100 psi | -40° | 150 | 120° | 0.01 | 0.008 | Aluminum, PVC, Zinc | 2 1/8" | 8 1/2" | 0000000 | 00000000 | 0000000 | 000000 | 0000000 | 00000 |

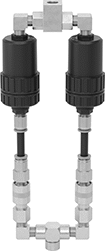

Automatic Shut-Off Compressed Air Dryers

Stop moisture from reaching tools and equipment. These dryers have a polypropylene filter element that expands when wet, shutting off airflow until the element is replaced. They remove any remaining moisture in your air line that aftercoolers and separators don’t catch. Install them as close as possible to sensitive devices such as plasma cutters and paint guns. Because airflow will stop without warning, you should only use these dryers in systems where a sudden shutoff won’t damage tools and equipment. To prevent debris from clogging the filter element, install them after an oil filter.

Dual air dryers keep your system running if one filter shuts down. Their auto-switch valve redirects airflow to the other filter as soon as saturation is reached. You can also replace filters one at a time without stopping airflow to the entire system. The valve’s position shows which dryer is in use.

Dryers | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Inlet | Outlet | Overall | Replacement Filter Element Kits | |||||||||||||

| Pipe Size | Connection | Pipe Size | Connection | Max. Flow Rate | Dew Point Temp., °F | Max. Temp., °F | Max. Pressure, psi | Housing Material | Dia. | Ht. | Wd. | Dp. | Each | Each | ||

Nylon Plastic Bowl—Opaque | ||||||||||||||||

Air Dryer | ||||||||||||||||

| 1/4 | NPT Male | 1/4 | NPT Female | 25 scfm @ 125 psi | -20° | 150° | 125 | Nylon Plastic | 1 7/8" | 4" | __ | __ | 00000000 | 0000000 | 00000000 | 000000 |

Dual Air Dryer | ||||||||||||||||

| 1/4 | NPT Male | 1/4 | NPT Female | 25 scfm @ 125 psi | -20° | 150° | 125 | Nylon Plastic | __ | 12 5/8" | 5" | 1 7/8" | 00000000 | 000000 | 00000000 | 00000 |

Compressed Air Separators

Prevent equipment damage caused by moisture. The first step in water removal, these separators remove the water that accumulates as compressed air cools. They have a float-operated drain valve that automatically opens when the bowl begins to fill. Install in your air line after compressors and aftercoolers.

Separators with a sight glass allow you to see inside the bowl to monitor its contents.

Inlet | Outlet | Overall | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Connection | Pipe Size | Connection | Max. Flow Rate | Max. Pressure, psi | Max. Temp., °F | Ht. | Wd. | Dp. | Each | |

Aluminum Housing with Sight Glass | |||||||||||

| 1/4 | NPT Female | 1/4 | NPT Female | 26 scfm @ 100 psi | 145 | 140° | 7 3/8" | 3" | 3" | 0000000 | 0000000 |

Zinc Housing | |||||||||||

| 1/4 | NPT Female | 1/4 | NPT Female | 25 scfm @ 100 psi | 200 | 150° | 6 1/2" | 3" | 2 5/8" | 00000000 | 000000 |

Compressed Air Separators for Oil Removal

In addition to removing large amounts of water, these separators also remove particles and oil droplets. Place them after your compressor and aftercooler, or at the point of use in applications that don't require an aftercooler. They have an automatic drain to discharge the moisture.

Separators with a polycarbonate plastic bowl are clear, so you can see inside to monitor contents.

Separators | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Size | Overall | Replacement Filter Elements | |||||||||||

| Inlet | Outlet | Max. Flow Rate | Max. Pressure, psi | Max. Temp., °F | Removes Particle Size Down To, microns | Removes Oil Content Down To, ppm | Ht. | Wd. | Dp. | Each | Each | ||

Polycarbonate Plastic Bowl—Clear | |||||||||||||

| 1/4 | 1/4 | 26 scfm @ 100 psi | 145 | 140° | 1 | 5 | 9 1/2" | 2 1/8" | 2 1/8" | 0000000 | 0000000 | 0000000 | 000000 |

SMC Modular Compressed Air Separators

Keep moisture from damaging your equipment. These separators remove the water that accumulates in your line as compressed air cools. They connect to other SMC units of the same series with joiner clamps (sold separately), even if the pipe sizes differ slightly, so you can customize your air preparation system. They have a float-operated drain valve that automatically opens when the bowl begins to fill. Install them in your air line after compressors and aftercoolers.

Joiner clamps (sold separately) create compact, airtight connections that are easy to swap out. They come with mounting brackets to attach the separator to a wall or equipment.

Mounting brackets (sold separately) allow you to attach the separator to a wall or equipment.