About Air Preparation

More

Desiccant Compressed Air Dryers

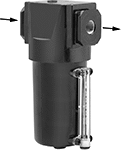

Once aftercoolers and separators have removed the bulk of the water, use these dryers to remove any remaining moisture in your air line. To reuse saturated desiccant, heat it in an oven at its reactivation temperature—you'll know it's dry when the color changes. Install these dryers after an oil filter to protect the desiccant.

Dryers with a clear bowl or a sight glass let you keep an eye on the contents inside. Dryers with a metal bowl are more durable than those with a plastic bowl, and they hold up to vapor better.

Dryers | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Size | O'all | Repair Kits | Element Kits | Replacement Desiccants | ||||||||||||

| Inlet | Outlet | Connections | Max. Flow Rate | Dew Point Temp., °F | Max. Temp., °F | Max. Pressure, psi | Housing Material | Ht. | Each | Each | Each | Each | ||||

Zinc Bowl—Opaque with Sight Glass | ||||||||||||||||

| 3/8 | 3/8 | NPT Female | 5 scfm @ 100 psi | -30° | 120° | 250 | Aluminum | 8 1/4" | 0000000 | 0000000 | 0000000 | 000000 | 0000000 | 000000 | 000000 | 000000 |

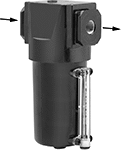

High-Pressure Desiccant Compressed Air Dryers

Get dry compressed air in high-pressure systems—these dryers have a maximum pressure rating of 300 psi. Once aftercoolers and separators have removed the bulk of the water, they remove any remaining moisture in your air line. Install after an oil filter to protect the desiccant. They have a sight glass so you can see inside the bowl to monitor contents.

Desiccant (sold separately) is required to remove moisture from air. To reuse saturated desiccant, heat it at its reactivation temperature until it returns to its dry color.

Norgren Modular Desiccant Compressed Air Dryers

For use with Norgren modular compressed air systems, once aftercoolers and separators have removed the bulk of the water, use one of these desiccant-filled dryers to remove any remaining moisture in your air line. Install after an oil filter to protect the desiccant. They have a clear bowl so you can see inside to monitor contents. To reuse saturated desiccant, heat it at its reactivation temperature until it returns to its dry color.

Use a joiner clamp (sold separately) to connect your dryer to another Norgren modular component.

End block sets (sold separately) allow you to swap out filter/regulator/lubricator components without unthreading your air line connections. The blocks remain connected to your pipe while you replace components between them.

Dryers | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Size | Overall | Joiner Clamps | End Block Sets | |||||||||||

| Inlet | Outlet | Connections | Max. Flow Rate | Max. Pressure, psi | Max. Temp., °F | Ht. | Wd. | Dp. | Each | Each | Each | |||

Aluminum Housing | ||||||||||||||

Polycarbonate Plastic Bowl—Clear with Steel Guard | ||||||||||||||

| 3/8 | 3/8 | NPT Female | 10 scfm @ 100 psi | 150 | 125° | 7 1/4" | 3 1/4" | 2 15/16" | 0000000 | 0000000 | 000000 | 000000 | 0000000 | 000000 |

Automatic Continuous-Use Desiccant Compressed

Air Dryers with Filters for Oil and Particle Removal

For an uninterrupted supply of clean, dry compressed air, these dryers have two desiccant towers. While desiccant in one tower absorbs moisture, the desiccant in the other is drying out, then they switch automatically. In addition to water, they also remove compressor oil and particles to extend their life and the components downstream from them. Install them after separators and aftercoolers, which remove the bulk of the moisture.

Style A are compact and quiet, making them ideal for point-of-use drying on shop floors. A display shows real-time drying data and alerts you for maintenance.

Style B have multiple inlets and outlets for mounting versatility—install them horizontally or vertically. They’re often used in industrial automation and manufacturing. Replacement filter elements help remove oil and particles and extend equipment life. Replacement service kits include desiccant cartridges, O-rings, and washers.

Dryers | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Size | Overall | Replacement Filter Elements | Replacement Service Kits | ||||||||||||||||||

| Style | Inlet | Outlet | Connections | Max. Flow Rate | Dew Point Temp., °F | Max. Pressure, psi | Max. Temp., °F | Removes Particle Size Down To, microns | Removes Oil Content Down To, ppm | Housing Material | Bowl Material | Voltage | Ht. | Wd. | Dp. | Each | Each | Each | |||

| A | 3/8 | 3/8 | NPT Female | 3 scfm @ -40° F | -40° | 200 | 120° | 0.1 | 0.03 | ABS Plastic | Aluminum | 120V AC | 16 3/4" | 9 3/8" | 8 3/8" | 0000000 | 000000000 | 000000 | 00 | 000000 | 00 |

| A | 3/8 | 3/8 | NPT Female | 9 scfm @ -40° F | -40° | 200 | 120° | 0.1 | 0.03 | ABS Plastic | Aluminum | 120V AC | 32 1/2" | 9 3/8" | 8 3/8" | 0000000 | 00000000 | 000000 | 00 | 000000 | 00 |

| B | 3/8 | 3/8 | NPT Female | 25 scfm @ -40° F | -40° | 230 | 120° | 0.5 | 0.008 | Aluminum | Aluminum | 120V AC | 42" | 11" | 3 3/4" | 0000000 | 00000000 | 00000000 | 0000000 | 0000000 | 0000000 |

Compressed Air Separators

Prevent equipment damage caused by moisture. The first step in water removal, these separators remove the water that accumulates as compressed air cools. They have a float-operated drain valve that automatically opens when the bowl begins to fill. Install in your air line after compressors and aftercoolers.

Separators with a sight glass allow you to see inside the bowl to monitor its contents.

Inlet | Outlet | Overall | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Connection | Pipe Size | Connection | Max. Flow Rate | Max. Pressure, psi | Max. Temp., °F | Ht. | Wd. | Dp. | Each | |

Aluminum Housing with Sight Glass | |||||||||||

| 3/8 | NPT Female | 3/8 | NPT Female | 53 scfm @ 100 psi | 145 | 140° | 8 5/8" | 3 5/8" | 3 1/2" | 0000000 | 0000000 |

Zinc Housing | |||||||||||

| 3/8 | NPT Female | 3/8 | NPT Female | 50 scfm @ 100 psi | 200 | 150° | 7 3/8" | 3 3/8" | 3" | 00000000 | 000000 |

Compressed Air Separators for Oil Removal

In addition to removing large amounts of water, these separators also remove particles and oil droplets. Place them after your compressor and aftercooler, or at the point of use in applications that don't require an aftercooler. They have an automatic drain to discharge the moisture.

Separators with an aluminum bowl are stronger than those with a polycarbonate plastic bowl—they won’t crack or shatter if dropped.

Separators | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Size | Overall | Replacement Filter Elements | Replacement Pressure Gauges | Replacement Automatic Drains | ||||||||||||||

| Inlet | Outlet | Max. Flow Rate | Max. Pressure, psi | Max. Temp., °F | Removes Particle Size Down To, microns | Removes Oil Content Down To, ppm | Ht. | Wd. | Dp. | Features | Each | Each | Each | Each | ||||

Aluminum Bowl—Opaque | ||||||||||||||||||

| 3/8 | 3/8 | 20 scfm @ 100 psi | 250 | 140° | 3 | 5 | 9 1/8" | 4 1/8" | 4 1/8" | Liquid-Level Indicator | 0000000 | 0000000 | 000000 | 0000000 | 0000000 | 000000 | 0000000 | 0000000 |

| 3/8 | 3/8 | 35 scfm @ 100 psi | 250 | 140° | 3 | 5 | 11 1/8" | 4 1/8" | 4 1/8" | Liquid-Level Indicator | 0000000 | 000000 | 000000 | 000000 | 0000000 | 00000 | 0000000 | 000000 |

| For Pipe Size Range | Ht. | Wd. | Dp. | Material | Mounting Fasteners Included | Each | |

| 3/8 to 1/2 | 4" | 2.94" | 3.39" | Powder-Coated Steel | Yes | 0000000 | 000000 |

SMC Modular Compressed Air Separators

Keep moisture from damaging your equipment. These separators remove the water that accumulates in your line as compressed air cools. They connect to other SMC units of the same series with joiner clamps (sold separately), even if the pipe sizes differ slightly, so you can customize your air preparation system. They have a float-operated drain valve that automatically opens when the bowl begins to fill. Install them in your air line after compressors and aftercoolers.

Joiner clamps (sold separately) create compact, airtight connections that are easy to swap out. They come with mounting brackets to attach the separator to a wall or equipment.

Mounting brackets (sold separately) allow you to attach the separator to a wall or equipment.