About Air Preparation

More

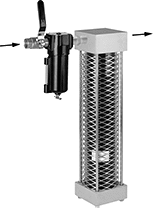

Desiccant Compressed Air Dryers with Filters for Oil and Particle Removal

Prevent damage to air-powered tools and equipment—these dryers remove water, compressor oil, and particles from your air supply. The dryer and oil filter share the same cartridge to save space and reduce downtime when changing them. No need to mess with desiccant beads. Install them after separators and aftercoolers, which remove the bulk of the moisture.

When selecting a dryer, keep in mind that the larger the desiccant capacity, the longer they last between cartridge changes.

Dryers with an opaque bowl have a sight glass, so you can monitor contents. Their twist-on design allows for fast, clean, tool-free maintenance. Dryers with a clear bowl are visible from all angles. They have a silica gel desiccant that changes from blue to pink, making it easy to know when to replace the cartridge. Disassembly is required to access the desiccant.

Dryers with a shut-off valve stop airflow when not in use to extend the life of the desiccant.

Dryers with a regulator monitor and adjust the flow of air.

Styles A-D have a particle filter before the dryer to remove large particles and protect the desiccant to extend its useful life.

Dryers | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Size | Overall | Replacement Desiccant | ||||||||||||||||||

| Style | Inlet | Outlet | Connections | Max. Flow Rate | Desiccant Capacity | Removes Particle Size Down To, microns | Removes Oil Content Down To, ppm | Dew Point Temp., °F | Pressure Regulating Range, psi | Max. Pressure, psi | Max. Temp., °F | Housing Material | Ht. | Wd. | Dp. | Gauge Included | Each | Each | ||

Polycarbonate Plastic Bowl—Opaque with Sight Glass | ||||||||||||||||||||

Air Dryer/Filter with Shut-Off Valve | ||||||||||||||||||||

| A | 1/2 | 1/2 | NPT Female | 40 scfm @ 120 psi | 1 1/2 qt. | 5 | 0.002 | -30° | __ | 120 | 120° | Aluminum | 23 1/2" | 10 3/4" | 5 1/8" | No | 00000000 | 0000000 | 00000000 | 000000 |

| A | 1/2 | 1/2 | NPT Female | 40 scfm @ 120 psi | 1 1/2 qt. | 40 | 0.002 | -30° | __ | 120 | 120° | Aluminum | 23 1/2" | 10 3/4" | 5 1/8" | No | 00000000 | 000000 | 00000000 | 00000 |

Air Dryer/Filter/Regulator with Shut-Off Valve | ||||||||||||||||||||

| B | 1/2 | 1/2 | NPT Female | 40 scfm @ 120 psi | 1 1/2 qt. | 5 | 0.002 | -30° | 5-120 | 120 | 120° | Aluminum | 23 1/2" | 14 1/4" | 5 1/8" | Yes | 00000000 | 000000 | 00000000 | 00000 |

| B | 1/2 | 1/2 | NPT Female | 40 scfm @ 120 psi | 1 1/2 qt. | 40 | 0.002 | -30° | 5-120 | 120 | 120° | Aluminum | 23 1/2" | 14 1/4" | 5 1/8" | Yes | 00000000 | 000000 | 00000000 | 00000 |

Polycarbonate Plastic Bowl—Clear | ||||||||||||||||||||

Air Dryer/Filter with Shut-Off Valve | ||||||||||||||||||||

| C | 1/2 | 1/2 | NPT Female | 40 scfm @ 120 psi | 2 qt. | 5 | 0.002 | -30° | __ | 120 | 120° | Aluminum | 23 1/2" | 10" | 4" | No | 00000000 | 000000 | 0000000 | 000000 |

| C | 1/2 | 1/2 | NPT Female | 40 scfm @ 120 psi | 2 qt. | 40 | 0.002 | -30° | __ | 120 | 120° | Aluminum | 23 1/2" | 10" | 4" | No | 0000000 | 000000 | 0000000 | 000000 |

Air Dryer/Filter/Regulator with Shut-Off Valve | ||||||||||||||||||||

| D | 1/2 | 1/2 | NPT Female | 40 scfm @ 120 psi | 2 qt. | 5 | 0.002 | -30° | 5-120 | 120 | 120° | Aluminum | 23 1/2" | 13 1/2" | 4" | Yes | 00000000 | 000000 | 0000000 | 000000 |

| D | 1/2 | 1/2 | NPT Female | 40 scfm @ 120 psi | 2 qt. | 40 | 0.002 | -30° | 5-120 | 120 | 120° | Aluminum | 23 1/2" | 13 1/2" | 4" | Yes | 0000000 | 000000 | 0000000 | 000000 |

Desiccant Compressed Air Dryers with Filters for Oil Removal

Remove water and compressor oil from your air line to prevent damage to air-powered tools and equipment. The dryer and filter share the same cartridge to save space and reduce downtime when changing them. Install them after separators and aftercoolers to remove the bulk of the moisture, and after a particle filter to protect the desiccant.

Dryers with a clear bowl are visible from all angles. They have silica gel desiccant that changes from blue to pink, making it easy to know when to replace the cartridge. Disassembly is required to access the desiccant.

Dryers | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Size | Overall | Replacement Desiccant | |||||||||||||||||

| Inlet | Outlet | Connections | Max. Flow Rate | Desiccant Capacity, qt. | Dew Point Temp., °F | Max. Pressure, psi | Max. Temp., °F | Removes Particle Size Down To, microns | Removes Oil Content Down To, ppm | Filter Service Indicator Included | Housing Material | Ht. | Wd. | Dp. | Gauge Included | Each | Each | ||

Polycarbonate Plastic Bowl—Clear | |||||||||||||||||||

| 1/2 | 1/2 | NPT Female | 40 scfm @ 120 psi | 2 | -30° | 120 | 120 | 0.4 | 0.002 | No | Aluminum | 21" | 4" | 4" | No | 0000000 | 0000000 | 0000000 | 0000000 |