How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

About Actuated On/Off Valves

More

About Gradual On/Off Valves

More

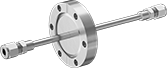

Flanged Through-Wall Fittings for Ultra-High-Vacuum Chambers

- For Use With: See table

- Environment Temperature Range: 32° to 300° F

- Process Temperature Range: -325° to 995° F

- Tubing: Use with 304/304L or 316/316L stainless steel

Bolt these fittings onto your ultra-high-vacuum chamber to transfer liquids and gases inside. Also known as feedthroughs, they come assembled with a flanged (CF) fitting, metal tubing, and two Yor-Lok tube fittings. Their bolt-together connection forms the tightest seal of any fitting type, so you can use them in semiconductor manufacturing, surface analysis experiments, and even research with particle accelerators. Made of stainless steel and copper, these fittings resist rusting. These fittings are not for use in pressure applications.

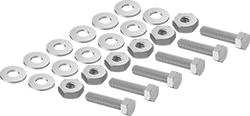

To complete the flanged connection, you’ll need a gasket and bolt kit (each sold separately). The Yor-Lok fittings on each end include a nut and two sleeves that grip your system’s stainless steel tubing.

Bolt Holes | For Tube | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Flange OD | High-Vacuum Flange Size | High Vacuum Connection Type | Bolt Circle Dia. | Dia. | No. of | Connection Style | OD | Wall Thick. | Lg. | Max. Vacuum | Material | Each | |

For Use With Liquid Helium, Liquid Methane, Liquid Nitrogen, Liquid Oxygen | |||||||||||||

| 1 21/64" | 16 | CF | 1 1/16" | 11/64" | 6 | Yor-Lok | 1/4" | 0.028"-0.095" | 9" | 10 -13 torr @ 72° F | 304 Stainless Steel | 3441N21 | 0000000 |

| 2 3/4" | 40 | CF | 2 5/16" | 17/64" | 6 | Yor-Lok | 1/4" | 0.028"-0.095" | 9" | 10 -13 torr @ 72° F | 304 Stainless Steel | 3441N22 | 000000 |

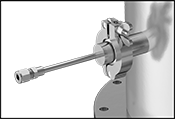

Quick-Clamp Through-Wall Fittings for High-Vacuum Chambers

- For Use With: See table

- Environment Temperature Range: 32° to 300° F

- Process Temperature Range: -325° to 995° F

- Tubing: Use with 304/304L or 316/316L stainless steel

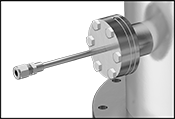

- Specifications Met: ISO 2861

Transfer liquids and gases into high-vacuum chambers with these assembled fittings, also known as feedthroughs. Their quick-clamp (ISO-KF) connections are easier to install and remove than bolt-on flanges. This makes them a good choice for systems that need frequent cleaning, repairs, and setup changes, such as those in teaching and research labs. These fittings meet ISO 2861, which means they’re made to strict dimensional standards that ensure vacuum-tight connections. Made of stainless steel and aluminum, these fittings resist rusting. They are not for use in pressure applications.

These fittings are ready to install and include quick-clamp fittings, metal tubing, and Yor-Lok tube fittings at each end. The Yor-Lok fittings include a nut and two sleeves that grip your system’s stainless steel tubing. To complete the quick-clamp connection, you’ll need a clamp and ring (each sold separately).

For Tube | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Flange OD | High-Vacuum Flange Size | High Vacuum Connection Type | Connection Style | OD | Wall Thick. | Lg. | Max. Vacuum | Material | Each | |

For Use With Liquid Helium, Liquid Methane, Liquid Nitrogen, Liquid Oxygen | ||||||||||

| 1.18" | 16 | ISO-KF | Yor-Lok | 1/4" | 0.028"-0.095" | 9" | 10 -8 torr @ 72° F | 304 Stainless Steel | 3441N11 | 0000000 |

| 1.57" | 25 | ISO-KF | Yor-Lok | 1/4" | 0.028"-0.095" | 9" | 10 -8 torr @ 72° F | 304 Stainless Steel | 3441N12 | 000000 |

| 2.16" | 40 | ISO-KF | Yor-Lok | 1/4" | 0.028"-0.095" | 9" | 10 -8 torr @ 72° F | 304 Stainless Steel | 3441N13 | 000000 |

| 2.95" | 50 | ISO-KF | Yor-Lok | 1/4" | 0.028"-0.095" | 9" | 10 -8 torr @ 72° F | 304 Stainless Steel | 3441N14 | 000000 |

| For Flange OD | For High-Vacuum Flange Size | High Vacuum Connection Type | Material | Max. Vacuum | Each | |

With Wing Nut | ||||||

|---|---|---|---|---|---|---|

| 1.18" | 10, 16 | ISO-KF | Aluminum | 10 -8 torr @ 72° F | 4518K711 | 00000 |

| 1.57" | 25 | ISO-KF | Aluminum | 10 -8 torr @ 72° F | 4518K72 | 00000 |

| 2.16" | 40 | ISO-KF | Aluminum | 10 -8 torr @ 72° F | 4518K73 | 00000 |

| 2.95" | 50 | ISO-KF | Aluminum | 10 -8 torr @ 72° F | 4518K74 | 00000 |

Material | |||||||

|---|---|---|---|---|---|---|---|

| For Flange OD | For High-Vacuum Flange Size | High Vacuum Connection Type | O-Ring | Inner Ring | Max. Vacuum | Each | |

| 1.18" | 16 | ISO-KF | Viton® Fluoroelastomer Rubber | 304 Stainless Steel | 10 -8 torr @ 72° F | 4518K621 | 00000 |

| 1.57" | 25 | ISO-KF | Viton® Fluoroelastomer Rubber | 304 Stainless Steel | 10 -8 torr @ 72° F | 4518K63 | 00000 |

| 2.16" | 40 | ISO-KF | Viton® Fluoroelastomer Rubber | 304 Stainless Steel | 10 -8 torr @ 72° F | 4518K64 | 00000 |

| 2.95" | 50 | ISO-KF | Viton® Fluoroelastomer Rubber | 304 Stainless Steel | 10 -8 torr @ 72° F | 4518K65 | 00000 |

Threaded Gradual On/Off Valves for Cryogenic Liquid

- Valve Type: Gate

- For Use With: Liquid Argon, Liquid Carbon Dioxide, Liquid Natural Gas, Liquid Methane, Liquid Nitrogen, Liquid Oxygen

- Packing Material: PTFE Plastic

- Specifications Met: ASME B31.3, CGA G-4.1, MSS-SP-80

Built to handle the extreme cold of liquid gases, these bronze valves are ideal for liquid carbon dioxide carbonation systems, liquid nitrogen coolant systems, and other cryogenic applications. They’ll also work with liquified natural gas and liquid oxygen. They’re cleaned and bagged to meet CGA G-4.1 for oxygen service. Also known as gate valves, they open and close gradually with multiple turns of the wheel handle to prevent sudden starts and stops.

The handle raises as these valves open and lowers as they close. At a glance, you can see if flow is on or off. The stem is isolated from what’s flowing through your line, giving these valves a longer lifespan than valves with a nonrising stem. They have a threaded union stem housing, so you can separate the stem from the housing while the valve is inline. That means you can complete maintenance tasks, such as packing the stem, without taking apart your whole setup.

O'all | Stem | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Temp. Range, °F | End-to-End Lg. | Ht. | Lg. | Type | Housing Connection Style | Each | |

NPT Female | ||||||||||

Wheel Handle—Bronze Body and Brass Gate | ||||||||||

| 1/2 | 19.8 | 600 psi @ 72° F | -320° to 150° | 2 5/16" | 10 3/16" | 2 5/16" | Rising | Threaded Union | 7224N11 | 0000000 |

| 3/4 | 36 | 600 psi @ 72° F | -320° to 150° | 2 1/2" | 11 5/16" | 2 1/2" | Rising | Threaded Union | 7224N12 | 000000 |

| 1 | 60 | 600 psi @ 72° F | -320° to 150° | 2 7/8" | 13 1/2" | 2 7/8" | Rising | Threaded Union | 7224N13 | 000000 |

| 1 1/2 | 152 | 600 psi @ 72° F | -320° to 150° | 3 7/16" | 18 3/8" | 3 7/16" | Rising | Threaded Union | 7224N14 | 00000000 |

| 2 | 245 | 600 psi @ 72° F | -320° to 150° | 3 13/16" | 21 5/16" | 3 13/16" | Rising | Threaded Union | 7224N15 | 00000000 |

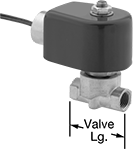

Solenoid On/Off Valves for Cryogenic Liquids

Built to withstand the extreme cold of liquid nitrogen and liquid oxygen, these valves are cleaned and bagged for high-purity applications. They operate on electricity to automatically start and stop flow.

All valves are normally closed unless actuated. The actuator is directly mounted to the valve body to minimize movement and reduce wear.

304 stainless steel valves are more corrosion resistant than brass and bronze valves.

Zero pressure drop valves don’t require a minimum pressure drop between the inlet and outlet for operation. Pressure drop assisted valves require a minimum pressure drop between the inlet and the outlet for operation; the upstream pressure must be greater than the downstream pressure.

NEMA 2 valves resist light splashing water and dust, and their enclosures are rated IP50 for additional protection from dust. Valves rated NEMA 4 and IP65 resist dust, splashing water, and washdowns.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

- For Use With: Liquid Argon, Liquid Nitrogen, Liquid Oxygen

- Seal Material: PTFE Plastic

| Pipe Size | Gender | Thread Type | Flow Coefficient (Cv) | Max. Pressure | Pressure Drop | Temp. Range, °F | Valve Lg. | O'all Ht. | Environmental Rating | Each | |

Normally Closed—120V AC | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/4 | Female | NPT | 0.7 | 120 psi @ 70° F | Zero Pressure Drop | -320° to 355° | 1 3/4" | 3 1/8" | IP50, NEMA 2 | 50585K23 | 0000000 |

| 3/8 | Female | NPT | 3.5 | 125 psi @ 70° F | Pressure Drop Assisted | -320° to 355° | 2 1/2" | 4 7/8" | IP50, NEMA 2 | 50585K38 | 000000 |

- For Use With: Liquid Argon, Liquid Nitrogen, Liquid Oxygen

- Seal Material: Glass-Filled PTFE Plastic

| Pipe Size | Gender | Thread Type | Flow Coefficient (Cv) | Max. Pressure | Pressure Drop | Temp. Range, °F | Valve Lg. | O'all Ht. | Each | |

Normally Closed—24V AC | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1/2 | Female | NPT | 3.5 | 110 psi @ -350° F | Zero Pressure Drop | -350° to 400° | 3 1/4" | 7" | 4710T21 | 0000000 |

| 3/4 | Female | NPT | 7.5 | 110 psi @ -350° F | Zero Pressure Drop | -350° to 400° | 3 1/2" | 7 1/8" | 4710T23 | 000000 |

| 1 | Female | NPT | 13 | 110 psi @ -350° F | Zero Pressure Drop | -350° to 400° | 4 1/8" | 8" | 4710T24 | 000000 |

Normally Closed—24V DC | ||||||||||

| 1/2 | Female | NPT | 3.5 | 110 psi @ -350° F | Zero Pressure Drop | -350° to 400° | 3 1/4" | 7" | 4710T22 | 000000 |

| 1 | Female | NPT | 13 | 110 psi @ -350° F | Zero Pressure Drop | -350° to 400° | 4 1/8" | 8" | 4710T25 | 000000 |

Normally Closed—120V AC | ||||||||||

| 1/2 | Female | NPT | 3.5 | 110 psi @ -350° F | Zero Pressure Drop | -350° to 400° | 3 1/4" | 7 1/16" | 4710T11 | 000000 |

| 1/2 | Female | NPT | 3.5 | 200 psi @ -350° F | Zero Pressure Drop | -350° to 400° | 3 1/4" | 7 1/16" | 4710T12 | 000000 |

| 3/4 | Female | NPT | 7.5 | 110 psi @ -350° F | Zero Pressure Drop | -350° to 400° | 3 1/2" | 7 3/8" | 4710T13 | 000000 |

| 1 | Female | NPT | 13 | 110 psi @ -350° F | Zero Pressure Drop | -350° to 400° | 4 1/8" | 8 1/8" | 4710T17 | 000000 |

- For Use With: Liquid Nitrogen, Liquid Oxygen

- Seal Material: PTFE Plastic

| Pipe Size | Gender | Thread Type | Flow Coefficient (Cv) | Max. Pressure | Pressure Drop | Temp. Range, °F | Valve Dia. | O'all Ht. | Environmental Rating | Each | |

Normally Closed—120V AC | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/4 | Female | NPT | 0.9 | 225 psi @ 120° F | Pressure Drop Assisted | -320° to 120° | 1 11/16" | 4 13/16" | IP65, NEMA 4 | 7902K41 | 0000000 |

| 3/8 | Female | NPT | 1.9 | 225 psi @ 120° F | Pressure Drop Assisted | -320° to 120° | 1 11/16" | 4 13/16" | IP65, NEMA 4 | 7902K42 | 000000 |

| 1/2 | Female | NPT | 2.8 | 225 psi @ 120° F | Pressure Drop Assisted | -320° to 120° | 1 11/16" | 5 1/4" | IP65, NEMA 4 | 7902K43 | 000000 |