High-Pressure Clamp-On Connectors

- For Use With: Bases, Drinking Water, Mild Acids, Salt Solutions

- Temperature Range: -20° to 180° F

- Specifications Met:

Pipe Size of 1/2-2: ASTM A307, ASTM A536, AWWA C-219, NSF/ANSI 61

Pipe Size of 3-8: ASTM A513, ASTM A53, ASTM A715, AWWA C-219, NSF/ANSI 61 - For Pipe Material: Iron, Steel, PVC Plastic

These heavy duty steel connectors are designed for high-pressure applications. Use them to connect rigid pipe of the same or different materials. They meet NSF/ANSI 61 safety standards for use with drinking water systems. To install, center the connector over two pipe ends and tighten the bolts with a wrench. They allow limited expansion and contraction; they do not restrain side-to-side movement.

| For Pipe OD | For Pipe Size | Lg. | No. of Bolts | Max. Pressure | Max. Vacuum | Material | Gasket Material | Each | |

| 0.84" | 1/2 | 7" | 2 | 500 psi @ 72° F | 15 in. of Hg @ 72° F | Steel | Buna-N Rubber | 0000000 | 000000 |

| 1.05" | 3/4 | 7" | 2 | 500 psi @ 72° F | 15 in. of Hg @ 72° F | Steel | Buna-N Rubber | 0000000 | 00000 |

| 1.315" | 1 | 7" | 2 | 500 psi @ 72° F | 15 in. of Hg @ 72° F | Steel | Buna-N Rubber | 0000000 | 00000 |

| 1.66" | 1 1/4 | 7" | 2 | 500 psi @ 72° F | 15 in. of Hg @ 72° F | Steel | Buna-N Rubber | 0000000 | 00000 |

| 1.9" | 1 1/2 | 7" | 2 | 500 psi @ 72° F | 15 in. of Hg @ 72° F | Steel | Buna-N Rubber | 0000000 | 00000 |

| 2.38" | 2 | 8" | 2 | 500 psi @ 72° F | 15 in. of Hg @ 72° F | Steel | Buna-N Rubber | 0000000 | 000000 |

| 3 1/2" | 3 | 6" | 3 | 500 psi @ 72° F | 15 in. of Hg @ 72° F | Steel | Buna-N Rubber | 0000000 | 000000 |

| 4 1/2" | 4 | 6" | 4 | 500 psi @ 72° F | 15 in. of Hg @ 72° F | Steel | Buna-N Rubber | 0000000 | 000000 |

| 5.563" | 5 | 8" | 4 | 500 psi @ 72° F | 15 in. of Hg @ 72° F | Steel | Buna-N Rubber | 0000000 | 000000 |

| 6 5/8" | 6 | 6" | 6 | 500 psi @ 72° F | 15 in. of Hg @ 72° F | Steel | Buna-N Rubber | 0000000 | 000000 |

| 8 5/8" | 8 | 6" | 6 | 500 psi @ 72° F | 15 in. of Hg @ 72° F | Steel | Buna-N Rubber | 0000000 | 000000 |

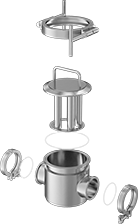

Sanitary Magnetic Strainers

- For Use With: Beverage, Dairy, Food, Salt Solutions, Sodium Nitrate, Water

- Max. Pressure: 150 psi @ 225° F

- Temp. Range: -20° to 225° F

Draw metal shavings and other contaminants out of your sanitary liquid line with these strainers. As liquid swirls through the strainer cavity, magnets sealed inside capture any metal bits. Remaining impurities are separated out with gravity and trapped in a collection sump. Empty the strainers by removing the lid and scooping up the collected particles at the bottom of the enclosure. These strainers have quick-clamp connections, so they’re good for frequent deep cleans and line changes. Also known as tri-clamp fittings, they connect with a gasket, a clamp, and another quick-clamp fitting for quick removal and assembly.

These strainers are 316 stainless steel, which won’t corrode from frequent washdowns with harsh cleaners. The continuous weld seams and polished surfaces are free of pits and crevices where bacteria could grow, making them easy to sanitize. Rated for high temperatures, you can keep these strainers on your line during a heated clean-in-place (CIP) process. All strainers and their included gasket are FDA compliant, meaning they are safe for food contact.

Filters that are USDA certified meet the highest standards of sanitary design.

| Pipe Size | Max. Magnetic Pull, lbs. | Lg. | Ht. | Magnet Material | Gasket Material | Specifications Met | Each | |

316 Stainless Steel | ||||||||

|---|---|---|---|---|---|---|---|---|

| 2 | 14.25 | 9 3/4" | 9 3/8" | Neodymium | Buna-N Rubber | FDA Compliant 21 CFR 177.2600 | 0000000 | 000000000 |

| 2 | 14.25 | 9 3/4" | 11 7/8" | Neodymium | Buna-N Rubber | FDA Compliant 21 CFR 177.2600 | 0000000 | 00000000 |

| 3 | 14.25 | 9 13/16" | 9 3/8" | Neodymium | Buna-N Rubber | FDA Compliant 21 CFR 177.2600 | 0000000 | 00000000 |

| 3 | 14.25 | 9 13/16" | 11 7/8" | Neodymium | Buna-N Rubber | FDA Compliant 21 CFR 177.2600 | 0000000 | 00000000 |