How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

Push-to-Connect Tube Fittings for Drinking Water

- Temperature Range: 35° to 150° F

- Tubing: See table

- Specifications Met: NSF/ANSI 61

Made of moisture-resistant acetal, these fittings won't absorb water and lose strength, even in high-humidity environments. Also known as instant fittings, they connect to tubing with a push, and an internal gripping ring and O-ring hold the tubing tight. To disconnect, push on the release ring and pull the tubing out of the fitting. All meet NSF/ANSI 61 for use in drinking water systems.

For Tube | ||||||||

|---|---|---|---|---|---|---|---|---|

| For Tube OD | Pipe Size | Material | Color | Release Ring Color | Max. Pressure | Material | Each | |

BSPP Threads | ||||||||

| 10mm | 5/8 | Acetal Plastic | Black | Black | 150 psi @ 72° F | Nylon Plastic, Polyethylene Plastic | 00000000 | 00000 |

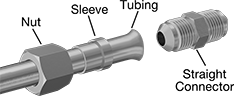

30° Flared Fittings for Steel Tubing

- Specifications Met: See table

Also known as JIS (Japanese Industrial Standard) fittings, these have a 30° flare on one or both ends. Fittings are zinc-plated steel for fair corrosion resistance.

- Temperature Range: -65° to 500° F

| For Tube OD | Pipe Size | Material | Max. Pressure | Specifications Met | Each | |

| 3/4" | 5/8 | Zinc-Plated Steel | 4,000 psi @ 72° F | ISO 228-1, JIS B 0202, JIS B 8363 | 00000000 | 000000 |

- Temperature Range: -65° to 500° F

| For Tube OD | Pipe Size | Material | Max. Pressure | Specifications Met | Each | |

| 3/4" | 5/8 | Zinc-Plated Steel | 4,000 psi @ 72° F | ISO 228-1, JIS B 0202, JIS B 8363 | 00000000 | 000000 |

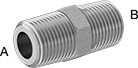

Compact Extreme-Pressure Steel Threaded Pipe Fittings

These fittings are strong enough to handle extreme pressures, yet small enough to fit into cramped spaces. They are zinc-plated steel, which have better corrosion resistance than plain steel fittings. BSPP and metric male threads have either a gasket, or a gasket and washer, to prevent leaks.

(SAE Straight) Male Threads

with Gasket and Washer

- For Use With: See table

- Specifications Met: See table

| Pipe Size (A) | Thread Size (B) | Max. Pressure | Material | For Use With | Specifications Met | Each | |

BSPP Male × Metric Male | |||||||

|---|---|---|---|---|---|---|---|

| 5/8 | M22 × 1.5 mm | 4,000 psi @ 72° F | Zinc Plated Steel | Air, Diesel Fuel, Gasoline, Hydraulic Fluid, Oil, Water | DIN 7631, ISO 1179, ISO 6149, ISO 8434-6, ISO 9974 | 00000000 | 000000 |

Male Threads with

Gasket and Washer

- For Use With: See table

- Specifications Met: See table

| Pipe Size | Plug Construction | Max. Pressure | Material | For Use With | Specifications Met | Each | |

BSPP Male | |||||||

|---|---|---|---|---|---|---|---|

| 5/8 | Hollow | 3,500 psi @ 72° F | Zinc Plated Steel | Air, Hydraulic Fluid, Oil, Water | ISO 1179, ISO 8434-6 | 00000000 | 00000 |

BSPT Male | |||||||

| 5/8 | Solid | 3,500 psi @ 72° F | Zinc Plated Steel | Air, Hydraulic Fluid, Oil, Water | DIN EN 10226-1, ISO 7-1 | 00000000 | 00000 |

Plastic Pipe Fittings for Oil

Made of corrosion-resistant plastic, these fittings won’t deteriorate when used in oil applications. They also have high strength and impact resistance. Apply a non-hardening, plastic-compatible sealant to the male threads to prevent leaks. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

- For Use With: Oil

- Maximum Temperature: 140° F

| Pipe Size | Material | Color | Maximum Pressure | Pkg. Qty. | Pkg. | |

BSPP | ||||||

|---|---|---|---|---|---|---|

| 5/8 | Polyethylene Plastic | Red | Not Rated | 10 | 0000000 | 00000 |

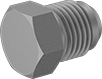

Nuts for High-Pressure Nipples for Compressed Gas

Slide a high-pressure hose nipple for compressed gas into one of these nuts to connect a pipe to the inlet of a pressure regulator. They are also known as CGA (Compressed Gas Association) nuts and inlet nuts.

Brass nuts have good corrosion resistance and are softer than 316 stainless steel nuts, so they're easier to thread together. Aluminum-plated brass nuts have better corrosion and wear resistance than unplated brass.

Note: Nuts have a CGA, BS, or DIN number that corresponds to a specific type of gas. Choose a nut with the same number as your tank and other system components.

- Maximum Pressure: See table

- Maximum Temperature: 120° F, except DIN 477 No. 12: 250° F

| Number | Pipe Size | Thread Type | Thread Direction | Max. Pressure | For Use With | Each | |

Aluminum-Plated Brass | |||||||

|---|---|---|---|---|---|---|---|

| BS 341 No. 3 | 5/8 | BSPT | Right Hand | 3,000 psi @ 72° F | Air, Argon, Helium, Krypton, Neon, Nitrogen, Oxygen, Perfluoropropane | 000000000 | 000000 |