About NEMA Straight-Blade Plugs, Connectors, and Receptacles

More

About NEMA Plugs, Sockets, and Receptacles

More

Hazardous Location Straight-Blade Plugs and Receptacles

Use connectors where ignitable gas and dust may be present. They are UL listed for Class I, Division 1 and 2, Groups C and D; Class II, Division 1 and 2, Groups F and G; and Class III hazardous environments.

Receptacles are compatible with both the NEMA 5-15 and 5-20 plugs.

Note: The current rating of your plug should not exceed that of your receptacle.

| NEMA Style | Voltage | Current | Wire Connection Type | Receptacle Terminal Location | Mounting Location | Environment | Environmental Rating | Color | Conduit Thread Type | Choose a Conduit Trade Size | Each | |

Grounded | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 5-20 | 125V AC | 20A | Screw Terminals | Back | Surface | Hazardous Location, Outdoor | NEC Class I Divisions 1, 2 Groups C, D NEC Class II Divisions 1, 2 Groups F, G NEC Class III Divisions 1, 2 NEMA 3 NEMA 7 NEMA 9 NEC Zone 1 Groups IIB, IIA | Gray | NPT | 0000000 | 0000000 | |

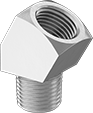

Grease Fitting Adapters

When the size or thread type of a fitting doesn't match an existing opening, use these adapters to make the connection.

Brass adapters resist corrosion better than zinc-plated steel adapters.

Connection | ||||

|---|---|---|---|---|

| Male | Female | Material | Each | |

Adapters | ||||

| NPT 1/8 | NPT 1/8 | Brass | 00000000 | 000000 |

Gas Chimney Vents and Fittings

For use with gas-fired equipment, such as boilers and furnaces, these vent pipes and fittings withstand temperatures up to 400° F. Also known as type B gas vents.

To join pipes and connectors, insert a male end into a female end and secure with the included locking band.

Adjustable-angle elbow connectors can be used at an angle or straight.