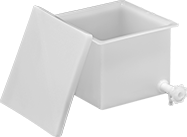

Rectangular Plastic Batch Cans with Faucet

A built-in faucet allows easy dispensing.

Bottom Inside | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., gal. | Wd. | Dp. | Ht. | Wd. | Dp. | Thick. | Color | Clarity | Lid Type | Faucet Material | Seal Material | Max. Temp., °F | Space Saving Features | Features | Each | |

Polyethylene Plastic | ||||||||||||||||

| 20 | 22 3/4" | 17 3/4" | 14" | 21" | 16" | 3/8" | White | Semi-Clear | Loose Fitting | Polyethylene Plastic | PTFE Plastic | 175° | Stackable | Seamless | 0000000 | 0000000 |

Round Plastic Batch Cans with Faucet

Use the faucet on these batch cans for easy dispensing.

| Cap., gal. | Dia. | Ht. | Bottom ID | Thick. | Color | Clarity | Lid Type | Faucet Material | Seal Material | Max. Temp., °F | Space Saving Features | Features | Each | |

Polyethylene Plastic | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 20 | 15 3/4" | 29 3/4" | 14" | 3/16" | White | Semi-Clear | Loose Fitting | Polypropylene Plastic | EPDM Rubber | 135° | Stackable | Seamless | 0000000 | 0000000 |

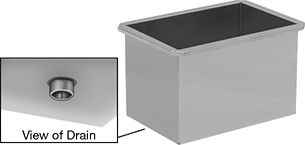

Rectangular Stainless Steel Batch Cans

316 stainless steel is more corrosion resistant than 304 stainless steel.

Batch cans with drain have a drain centered on the bottom of the can.

Stainless Steel Drums

These drums are corrosion resistant and are UN-compliant for shipping.

| Cap., gal. | Dia. | Ht. | Bottom ID | Gauge | Weight Cap., lbs. | Seal Material | Closing Ring Material | Space Saving Features | Shipping Standard | Each | |

304 Stainless Steel | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 20 | 19 1/2" | 21 1/2" | 18 1/4" | 18 | 350 | EPDM Rubber | Steel | Stackable | UN1A2/X160/S, UN1A2/Y1.5/150 | 0000000 | 0000000 |

Openings | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Cap., gal. | Dia. | Ht. | Gauge | Weight Cap. | Pipe Size | Gender | Space Saving Features | Shipping Standard | Each | |

304 Stainless Steel | ||||||||||

| 20 | 19 1/2" | 21 1/2" | 18 | Not Rated | 2 BSPP, 3/4 BSPP | Female | Stackable | UN1A1/X1.2/300 | 0000000 | 0000000 |

304 Stainless Steel | ||||

|---|---|---|---|---|

| For Drum Capacity, gal. | Gauge | Seal Material | Each | |

Lid with No Openings | ||||

| 30, 20 | 16 | EPDM Rubber | 0000000 | 0000000 |

| For Drum Capacity, gal. | Each | |

| 30, 20 | 0000000 | 000000 |

| For Drum Capacity, gal. | Each | |

Nut-and-Bolt Closing Ring | ||

|---|---|---|

| 30, 20 | 0000000 | 000000 |

Food Industry Stainless Steel Drums

In addition to being corrosion resistant, these drums have smooth, welded seams to prevent food and chemicals from collecting in crevices.

Sanitary Stainless Steel Drums

Store food, beverage, and pharmaceutical products in these drums, which have a sanitary design. Smooth, welded seams and a polished, seamless interior prevent product buildup and bacteria growth. Their EPDM rubber seal is FDA compliant for direct contact with food. Because they’re made of 316 stainless steel, these drums are also corrosion resistant.

To help you clean around and underneath these drums, these drums have a raised bottom. They’re also stackable to save space in your facility.

| Capacity, gal. | Diameter | Height | Bottom ID | Gauge | Weight Capacity | Seal Material | Closing Ring Material | Space Saving Features | Specifications Met | Each | |

316 Stainless Steel | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 20 | 19 3/4" | 21" | 19 3/4" | 16 | Not Rated | EPDM Rubber | 304 Stainless Steel | Stackable | FDA Compliant 21 CFR 177.2600 | 00000000 | 000000000 |

| For Drum Capacity, gal. | Seal Material | Each | |

316 Stainless Steel Lid with No Openings | |||

|---|---|---|---|

| 20 | EPDM Rubber | 00000000 | 0000000 |

| For Drum Capacity, gal. | Material | Each | |

| 20 | EPDM Rubber | 00000000 | 000000 |

| For Drum Capacity, gal. | Each | |

304 Stainless Steel Leverlock Closing Ring | ||

|---|---|---|

| 20 | 00000000 | 0000000 |

Steel Drums

All drums are UN-compliant for shipping.

Each | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., gal. | Dia. | Ht. | Bottom ID | Gauge | Weight Cap., lbs. | Color | Seal Material | Closing Ring Material | Space Saving Features | Shipping Standard | 1-3 | 4-Up | |

Painted Steel | |||||||||||||

| 20 | 19 1/2" | 21 1/2" | 18 1/4" | 18 | 475 | Black | EPDM Rubber | Steel | Stackable | UN1A2/X220/S, UN1A2/Y1.5/150 | 0000000 | 0000000 | 0000000 |

Each | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., gal. | Dia. | Ht. | Bottom ID | Gauge | Weight Cap., lbs. | Color | Seal Material | Closing Ring Material | Space Saving Features | Shipping Standard | 1-3 | 4-Up | |

Painted Steel | |||||||||||||

| 20 | 19 1/2" | 21 1/2" | 18 1/4" | 18 | 475 | Black | EPDM Rubber | Steel | Stackable | UN1A2/X220/S | 0000000 | 0000000 | 0000000 |

Openings | Each | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., gal. | Dia. | Ht. | Bottom ID | Gauge | Weight Cap., lbs. | Color | Seal Material | Closing Ring Material | Pipe Size | Gender | Space Saving Features | Shipping Standard | 1-3 | 4-Up | |

Painted Steel | |||||||||||||||

| 20 | 19 1/2" | 21 1/2" | 18 1/4" | 18 | 475 | Black | EPDM Rubber | Steel | 2 NPSM, 3/4 NPSM | Female | Stackable | UN1A2/X220/S | 00000000 | 0000000 | 0000000 |

Openings | Each | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., gal. | Dia. | Ht. | Gauge | Weight Cap. | Color | Pipe Size | Gender | Space Saving Features | Shipping Standard | 1-3 | 4-Up | |

Painted Steel | ||||||||||||

| 20 | 19 1/2" | 21 3/4" | 20 | Not Rated | Black | 2 NPSM, 3/4 NPSM | Female | Stackable | UN1A1/X1.2/300 | 0000000 | 0000000 | 0000000 |

Each | |||

|---|---|---|---|

| For Drum Capacity, gal. | 1-3 | 4-Up | |

| 30, 20 | 0000000 | 000000 | 000000 |

Corrosion-Resistant Steel Drums

The inside of these drums is epoxy coated to resist rust. Drums are UN-compliant for shipping.

| Cap., gal. | Dia. | Ht. | Bottom ID | Gauge | Weight Cap., lbs. | Color | Seal Material | Closing Ring Material | Space Saving Features | Shipping Standard | Each | |

Painted Steel | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 20 | 19 1/2" | 21 1/2" | 18 1/4" | 18 | 475 | Black | EPDM Rubber | Steel | Stackable | UN1A2/X220/S, UN1A2/Y1.5/150 | 00000000 | 0000000 |

Leverlock Closing Ring

and Lid with No Openings

| Cap., gal. | Dia. | Ht. | Bottom ID | Gauge | Weight Cap., lbs. | Color | Seal Material | Closing Ring Material | Space Saving Features | Shipping Standard | Each | |

Painted Steel | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 20 | 19 1/2" | 21 1/4" | 18 1/4" | 18 | 475 | Black | EPDM Rubber | Steel | Stackable | UN1A2/X220/S | 00000000 | 0000000 |

| For Drum Capacity, gal. | Gauge | Each | |

Lid with No Openings | |||

|---|---|---|---|

| 30, 20 | 18 | 0000000 | 000000 |

| For Drum Capacity, gal. | Each | |

| 30, 20 | 0000000 | 000000 |

Fiber Drums

Store dry materials in these lightweight drums.

| Capacity, gal. | Weight Capacity, lbs. | Dia. | Ht. | Bottom ID | Color | Rim Material | Closing Ring Material | Max. Temp. | Space Saving Features | Each | |

Fiber | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 20 | 225 | 16" | 25 1/2" | 15 1/2" | Beige | Galvanized Steel | Steel | Not Rated | Stackable | 000000 | 000000 |

Salvage/Overpack Drums

Use these drums for secondary containment or for temporarily storing and transporting leaking containers. All drums are UN-compliant for shipping.

| For Drum Cap., gal. | Cap., gal. | Weight Cap., lbs. | Dia. | Ht. | Bottom ID | Inside Ht. | Gauge | Color | Lid Color | Seal Material | Closing Ring Material | Space Saving Features | Shipping Standard | Each | |

With Nut-and-Bolt Closing Ring | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10, 5 | 20 | 425 | 18 3/4" | 21 1/2" | 18 1/4" | 19 1/4" | 18 | Yellow | Red | EPDM Rubber | Steel | Stackable | UN1A2/X220/S, UN1A2/Y1.5/150 | 0000000 | 0000000 |

With Leverlock Closing Ring | |||||||||||||||

| 10, 5 | 20 | 425 | 18 3/4" | 21 1/4" | 18 1/4" | 19 1/4" | 18 | Yellow | Red | EPDM Rubber | Steel | Stackable | UN1A2/X220/S | 0000000 | 000000 |

| For Drum Cap., gal. | Cap., gal. | Weight Cap., lbs. | Dia. | Ht. | Bottom ID | Inside Ht. | Thick. | Color | Seal Material | Max. Temp. | Space Saving Features | Shipping Standard | Each | |

| 5 | 20 | 150 | 22 1/2" | 19" | 17" | 17 1/2" | 1/8" | Yellow | Neoprene Rubber | Not Rated | Nestable, Stackable | UN1H2/X75/S | 0000000 | 000000 |

Easy-Grip Plastic Waste Containers, Lids, Dollies, and Caddies

These containers have two molded-in side handles and a durable bottom that stands up to dragging across the floor. They meet NSF/ANSI standards for food equipment.

For Container | |||||||

|---|---|---|---|---|---|---|---|

| Style | Capacity, gal. | Weight Capacity, lbs. | Dia. | Ht. | Color | Each | |

| A | 20, 32, 44, 55 | 250 | 18 1/4" | 7" | Black | 0000000 | 000000 |

Metal Waste Containers with Lift-Off Lid

A galvanized finish protects these waste containers from rust.

| Capacity, gal. | Dia. | Ht. | Circumference | For Use Outdoors | Material | Each | ||

| C | 20 | 18" | 23 1/2" | 57" | Yes | Galvanized Steel | 000000 | 000000 |

Metal Waste Containers

Styles A and B have a raised bottom to insulate and protect floors from heat transfer.

| Style | Capacity, gal. | Dia. | Ht. | Circumference | Material | Features | Color | Each | |

| A | 20 | 16" | 29" | 50" | Steel | Raised Bottom | Gray | 0000000 | 000000 |

Easy-Grip Plastic Recycling Containers, Lids, and Dollies

These containers have two molded-in side handles and a durable bottom that stands up to dragging across the floor.

Rectangular Plastic Tanks

Store large quantities of liquid in these flat-bottomed tanks. They have vented fill caps so air can flow in and out.

Drain | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., gal. | Wd. | Dp. | Ht. | Thick. | Fill Opening Dia. | Grad. Marks | Color | Clarity | Pipe Size | Gender | Max. Temp., °F | UV Protection | Includes | Each | |

Polyethylene Plastic | |||||||||||||||

| 20 | 15" | 11" | 31" | 1/4" | 5" | 1 gal. | White | Semi-Clear | 1/2 NPT | Female | 120° | UV Resistant | Vented Fill Cap | 0000000 | 0000000 |

| For Fill Opening Dia. | Features | Each | |

Polypropylene Plastic | |||

|---|---|---|---|

| 5" | Vent | 0000000 | 000000 |

Double-Wall Plastic Tanks

No need for separate spill-control pallets or trays—comply with EPA regulations for storing hazardous liquids with just one tank. These tanks have two walls, so if the primary compartment ruptures, the secondary one will contain the leak. It can hold 110% of the primary tank's volume and will also protect it from damage in case of impact.

Made of polyethylene, these tanks can store a broader range of chemicals than steel double-wall tanks. The plastic contains UV inhibitors so they can be used outside.

These tanks have a flat space on top where you can mount a metering pump. Because these tanks meet NSF/ANSI 61 for drinking water, you can meter chemicals stored in them into your drinking water system.

| Cap., gal. | Wd. | Dp. | Ht. | Primary Compartment Opening (No. of) | Secondary Compartment Opening (No. of) | Color | Max. Temp., °F | Specifications Met | Includes | Each | |

Polyethylene Plastic | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 20 | 18" | 18" | 24" | 8" Fill Opening Dia. (1) 3/8" Opening Dia. (1) 2 NPT Female Opening (2) | 1 NPT Female Opening (1) | Blue | 130° | EPA 40 CFR 264.175 NSF/ANSI 61 | Vented Fill Cap | 0000000 | 0000000 |

Portable Compressed Air Storage Tanks

Tanks with mounting plate have a platform for securing compressors, motors, and other components.

Ports | Overall | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., gal. | Max. Pressure, psi | Total No. of | Gender | Sizes | Lg. | Dia. | Ht. | Wall Thick. | Temp. Range, °F | Each | |

Horizontal with Mounting Plate and Wheels | |||||||||||

Powder-Coated Steel | |||||||||||

| 20 | 140 | 3 | Female | 1/2 NPT Port (2 ea.) 1/2 NPT Drain Port (1 ea.) | 33" | 14" | 29" | 1/8" | -20° to 450° | 0000000 | 0000000 |

ASME-Code Compressed Air Storage Tanks

These tanks have drain ports on the bottom to remove condensation. All other ports can be used as inlets or outlets in any configuration.

Tanks with mounting plate have a platform where you can secure motors, pumps, and other components.

Steel tanks are primed or powder coated for exterior corrosion resistance. Epoxy-lined steel tanks also resist interior corrosion that can result from moisture in your compressed air.

Safety regulations restrict sales to the listed jurisdictions/areas.

Note: Per ASME code, all tanks are water tested. Those made without a corrosion-resistant coating or material will have rust on the interior.

Ports | Overall | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., gal. | Max. Pressure, psi | Total No. of | Gender | Sizes | Lg. | Dia. | Ht. | Wall Thick. | Temp. Range, °F | Each | |

Horizontal | |||||||||||

Powder-Coated Steel | |||||||||||

| 20 | 200 | 8 | Female | 1/2 NPT Port (3 ea.) 3/4 NPT Port (2 ea.) 1 1/2 NPT Port (2 ea.) 1/4 NPT Drain Port (1 ea.) | 33 5/8" | 14" | 16" | 1/8" | -20° to 400° | 0000000 | 0000000 |

Epoxy-Lined Powder-Coated Steel | |||||||||||

| 20 | 200 | 8 | Female | 1/2 NPT Port (3 ea.) 3/4 NPT Port (1 ea.) 1 1/2 NPT Port (3 ea.) 1/4 NPT Drain Port (1 ea.) | 33 3/4" | 14" | 16" | 1/8" | -20° to 400° | 0000000 | 000000 |

Horizontal with Mounting Plate | |||||||||||

Powder-Coated Steel | |||||||||||

| 20 | 200 | 9 | Female | 1/4 NPT Port (1 ea.) 1/2 NPT Port (5 ea.) 1 1/2 NPT Port (2 ea.) 1/4 NPT Drain Port (1 ea.) | 33 5/8" | 14" | 18" | 1/8" | -20° to 400° | 0000000 | 000000 |

Epoxy-Lined Powder-Coated Steel | |||||||||||

| 20 | 200 | 9 | Female | 1/4 NPT Port (1 ea.) 1/2 NPT Port (4 ea.) 1 1/2 NPT Port (3 ea.) 1/4 NPT Drain Port (1 ea.) | 33 3/4" | 14" | 18" | 1/8" | -20° to 400° | 0000000 | 000000 |

Vertical | |||||||||||

Powder-Coated Steel | |||||||||||

| 20 | 200 | 5 | Female | 3/4 NPT Port (2 ea.) 1 1/2 NPT Port (2 ea.) 1/2 NPT Drain Port (1 ea.) | __ | 14" | 35" | 1/8" | -20° to 400° | 000000 | 000000 |

Hydraulic Tanks

Store fluids for a hydraulic power unit or circulating-oil system. Choose a tank capacity about three times greater than your requirement to allow for heat dissipation. Tanks with only a drain connection require you to drill your own inlet/outlet connection and add pipe suction flanges (sold separately). Flanges seal pipes that pass through the top plate of your tank.

Dual chamber tanks have a divider that allows particles to settle on one side before fluid is returned to your line.

Breather vents prevent excess pressure in tanks and allow a free flow of air. To install the breather vent to Style C tanks, drill a hole in the tank.

Mounting Hole | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Pipe Size | For Cutout Dia. | Material | Mounting Fasteners Included | Ctr.-to-Ctr. | Lg. | Wd. | Includes | Each | |

| 1/2 | 4 5/16" | Steel | Yes | 4 1/4" | 7/8" | 7/16" | Top Plate, Bottom Plate, Gasket, Washer | 00000000 | 000000 |

| 3/4 | 4 5/16" | Steel | Yes | 4 1/4" | 7/8" | 7/16" | Top Plate, Bottom Plate, Gasket, Washer | 00000000 | 00000 |

| 1 1/4 | 4 5/16" | Steel | Yes | 4 1/4" | 7/8" | 7/16" | Top Plate, Bottom Plate, Gasket, Washer | 00000000 | 00000 |

| 1 1/2 | 4 5/16" | Steel | Yes | 4 1/4" | 7/8" | 7/16" | Top Plate, Bottom Plate, Gasket, Washer | 00000000 | 00000 |

| 2 | 4 5/16" | Steel | Yes | 4 1/4" | 7/8" | 7/16" | Top Plate, Bottom Plate, Gasket, Washer | 00000000 | 00000 |

Material | Strainer | Mounting Hole | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Cutout Dia. | Cap | Strainer | Gasket | Removes Particle Size Down To, microns | Cap Dia. | Flange Dia. | Dia. | Ht. | Mounting Fasteners Included | Lg. | Wd. | Bolt Circle Dia. | Each | |

| 2 1/8" | Zinc-Plated Steel | Plastic | Rubber | 40 | 3" | 3 1/4" | 1 7/8" | 3 13/16" | Yes | 1/4" | 3/16" | 2 7/8" | 00000000 | 000000 |

For Hole | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dia. | No. of | Connection Ctr.-to-Ctr. | Overall Ht. | Window Ht. | Body Wd. | For Max. Tank Wall Thick. | Max. Pressure | Temp. Range | Thermometer Temp. Range | Material | Guard Material | Window Material | Each | |

| 1/2" | 2 | 5" | 6 3/8" | 3 7/8" | 13/16" | 1/2" | 50 psi @ 70° F | -40° F to 210° F | 0° F to 220° F | Nylon Plastic | Steel | Nylon Plastic | 0000000 | 000000 |