Food Industry Plastic Storage Containers

Use these containers in food-processing facilities. All meet either NSF/ANSI standards for sanitary design in food environments or are FDA compliant for direct contact with food.

Containers that cannot be sold to the regions listed are restricted by local chemical regulations.

Containers | Tight-Fitting Lids | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., gal. | Grad. Marks | Lg. | Wd. | Ht. | Max. Temp., °F | Specifications Met | Space Saving Features | Features | Cannot Be Sold To | Clarity | Choose a Color | Each | Cannot Be Sold To | Each | ||

Polycarbonate Plastic | ||||||||||||||||

| 3.5 | __ | 18" | 12" | 6" | 212° | NSF/ANSI 2 | Nestable | Handles | CT, ME, VT | Clear | Clear | 0000000 | 000000 | CT, ME, VT | 0000000 | 000000 |

| 3.5 | 2 qt., 2 L | 18" | 12" | 6" | 212° | NSF/ANSI 2 | Nestable | Handles | CT, ME, VT | Semi-Clear | 0000000 | 00000 | CT, ME, VT | 0000000 | 00000 | |

Low-Outgassing Plastic Storage Containers

Tested to meet ASTM E595, a standard used by NASA, these PETG containers produce almost no volatile emissions that could damage sensitive electronics or cloud lenses. The test is conducted in a vacuum, so you can use them in clean rooms and other areas where air purity is critical.

| Cap. | Lg. | Wd. | Ht. | Lid Type | Max. Temp., °F | Space Saving Features | Specifications Met | Color | Each | |

PETG Plastic | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 3.5 gal. | 14" | 11" | 5" | Tight Fitting | 120° | Stackable | ASTM E595 | Clear | 00000000 | 0000000 |

Plastic Pans

Bottom Inside | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Capacity | Lg. | Wd. | Ht. | Lg. | Wd. | Material | Color | Autoclavable | Max. Temp., °F | Space Saving Features | Each | |

| D | 3 1/2 gal. | 16" | 11 3/4" | 4 3/8" | 12 1/2" | 8 1/2" | Polystyrene Plastic | Beige | No | Not Rated | Nestable | 0000000 | 000000 |

Food Industry Stainless Steel Pans

Pans | Loose-Fitting Lids | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Capacity | Lg. | Wd. | Ht. | Bottom Inside Length | Bottom Inside Width | Gauge | Space Saving Features | Specifications Met | Features | Each | Each | ||

Dull 300 Series Stainless Steel | ||||||||||||||

| A | 3 1/2 gal. | 20 3/4" | 12 3/4" | 4" | 19 1/8" | 11 1/4" | 22 | Nestable | NSF/ANSI 2 | Seamless | 000000 | 000000 | 0000000 | 000000 |

| D | 3 1/2 gal. | 13 7/8" | 12 3/4" | 6" | 12 7/8" | 11 3/4" | 22 | Nestable | NSF/ANSI 2 | Seamless | 0000000 | 00000 | 0000000 | 00000 |

Rectangular Stainless Steel Batch Cans

316 stainless steel is more corrosion resistant than 304 stainless steel.

Rubber and Plastic Pails

| Capacity, gal. | Dia. | Ht. | Bottom ID | Graduation Marks | Color | Autoclavable | Max. Temp., °F | Each | |

Polypropylene Plastic | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 3 1/2 | 10 3/4" | 13 1/2" | 8 3/8" | 1 qt. | White | Yes | 275° | 000000 | 0000000 |

Food Industry Stainless Steel Pails

These 300 series stainless steel pails meet NSF/ANSI standards and are often used in food-processing applications.

Style B has a second handle on the bottom for easy pouring.

Pails and Snap-Lock Lids

and Telescoping

Spout

Keep contents secure with these pails and tight-fitting lids.

Lids with tear tab have a tamper-evident sealing ring with tab.

Lids with telescoping spout allow controlled pouring.

Pails | Replacement Lids with Tear Tab | Lids with Tear Tab and Telescoping Spout | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity, gal. | Dia. | Ht. | Bottom ID | Seal Material | Max. Temp., °F | Specifications Met | Space Saving Features | Choose a Color | Each | Each | Each | |||

Polyethylene Plastic | ||||||||||||||

| 3 1/2 | 12" | 10 1/4" | 10 1/4" | EPDM Rubber | 140° | FDA Compliant 21 CFR 177.1520 | Nestable | 0000000 | 00000 | 0000000 | 00000 | 0000000 | 00000 | |

Spill-Control Trays

Bottom Inside | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Capacity | Lg. | Wd. | Ht. | Lg. | Wd. | Color | Space Saving Features | Each | |

Polyethylene Plastic | |||||||||

| 3 1/2 gal. | 36" | 24" | 1 1/2" | 32" | 20" | Black | Nestable | 000000 | 000000 |

UN-Compliant Shipping Pails with Twist-Lock Lids

These pails have a twist-lock lid that opens and closes without tools and provides a more secure seal than a snap-lock lid. They are tested to comply with United Nations regulations for packaging and shipping hazardous material over land, sea, or air. These regulations aim to prevent hazardous spills caused by accidents or rough package handling.

Open pails for hazardous solids by squeezing the release and turning the lid.

Neoprene seals provide an extra-tight closure in the lid.

Bail handles are flexible and comfortable to hold. You only need one hand to grab them.

Pails with a drip-free pouring lip have a solid rim for a clean, controlled pour.

Pails with a security ring help discourage tampering. When the pail is opened, the ring on the lid separates.

Note: It is the responsibility of the shipper to follow regulatory guidelines for properly packaging and labeling all hazardous materials and ensure the appropriate method for shipping.

| Cap., gal. | Dia. | Ht. | Color | Seal Material | Handle Type | Features | Max. Temp., °F | Shipping Standard | Choose a Lid Color | Each | |

For Shipping Hazardous Solids | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

Polyethylene Plastic | |||||||||||

| 3 1/2 | 11 5/8" | 11" | White | __ | Bail | Drip-Free Pouring Lip | 150° | UN1H2/Y19/S | 00000000 | 000000 | |

| 3 1/2 | 12 5/8" | 12 1/8" | White | Neoprene Rubber | Bail | Drip-Free Pouring Lip, Security Ring | 150° | UN1H2/Y19/S | 000000000 | 00000 | |

UN-Compliant Shipping Pails for Snap-Lock Lids

Add a tight-fitting, snap-lock lid to safely ship hazardous materials in these sturdy pails.

Lids (sold separately) have a Buna-N rubber seal for extra-tight closure.

Note: For one-time shipping only.

Absorption-Resistant UN-Compliant Shipping Pails for Snap-Lock Lids

Prevent the absorption and permeation of chemicals with these fluorinated pails. Add a tight-fitting, snap-lock lid to safely ship hazardous materials.

These pails are tested to comply with United Nations regulations for packaging and shipping hazardous material over land, sea, or air. These regulations aim to prevent hazardous spills caused by accidents or rough package handling.

Lids (sold separately) have a Buna-N rubber seal for extra-tight closure.

Note: For one-time shipping only. It is the responsibility of the shipper to follow regulatory guidelines for properly packaging and labeling all hazardous materials, and ensure the appropriate method for shipping.

UN-Compliant Shipping Pails with Tab-Lock Lids

These pails come matched with UN-specified lids to safely ship hazardous materials. The lid has a rubber seal for an extra-tight closure. These pails are tested to comply with United Nations regulations for packaging and shipping hazardous material over land, sea, or air. These regulations aim to prevent hazardous spills caused by accidents or rough package handling.

Pails with an epoxy liner are the most chemical resistant.

Use a closer (sold separately) to crimp the lid closed.

Note: It is the responsibility of the shipper to follow regulatory guidelines for properly packaging and labeling all hazardous materials, and ensure the appropriate method for shipping.

UN-Compliant Shipping Pails for Tab-Lock Lids

Add a lid to safely ship hazardous materials with these pails. The pail interior is lined with epoxy to prevent rust.

Lids (sold separately) have a latex seal for an extra-tight closure.

Use a closer (sold separately) to crimp the lid closed.

Note: These pails meet UN specifications for shipping only if used with the matching lid.

Metal Hand-Pump Sprayers

Pump the handle to pressurize the tank, then squeeze the trigger on the wand to spray. These sprayers are often used for degreasers, insecticides, disinfectants, cleaning solutions, and herbicides.

Style A, B, and C sprayers have a trigger that locks for continuous spray.

Style C sprayers are more impact resistant than other sprayers and have a reinforced hose to prevent cracking and leaking. They can be used with harsh liquids such as acetone (40%).

Note: The material of the parts can affect a sprayer's compatibility with a chemical or solution. Make sure the tank, seal, wand, and nozzle are suitable for your application.

Sprayers | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Fill Opening | Repair Kits | Replacement Trigger and Wand Kits | ||||||||||||||||

| Style | Cap., gal. | Dia. | Ht. | Tank Material | Seal Material | Color | Hose Lg. | Wand Lg. | Wd. | Dp. | Dia. | Includes | Each | Each | Each | |||

Flat Dispensing | ||||||||||||||||||

| C | 3 1/2 | 8 1/2" | 26 3/4" | Epoxy-Coated Steel | Viton® Fluoroelastomer Rubber | Red | 48" | 24" | __ | __ | 4 1/4" | Two Spray Nozzles | 0000000 | 0000000 | 0000000 | 000000 | 0000000 | 000000 |

| C | 3 1/2 | 9 1/2" | 27 1/4" | Stainless Steel | Viton® Fluoroelastomer Rubber | __ | 48" | 24" | 4" | 1 1/2" | __ | __ | 0000000 | 000000 | 0000000 | 00000 | 000000 | 00 |

| D | 3 1/2 | 8" | 26 1/2" | Epoxy-Coated Galvanized Steel | Viton® Fluoroelastomer Rubber | Black | 48" | 24" | 4 1/4" | 2 1/2" | __ | __ | 0000000 | 000000 | 0000000 | 00000 | 000000 | 00 |

Parts Washing Cans

Sized to fit on a benchtop, these cans save space and solution when cleaning small parts. They have a fusible link that closes the cover in the event of a fire.

| Cap., gal. | OD | O'all Ht. | Material | Specifications Met | Each | |

For Solvent-Based Solutions | ||||||

|---|---|---|---|---|---|---|

| 3 1/2 | 11 1/2" | 11 1/2" | Steel | FM Approved, UL Listed | 0000000 | 0000000 |

Parts Washing Cans with Removable Basket

Easily insert and remove parts from these cans. Good for small cleaning jobs, they save space and solution. A fusible link closes the cover in the event of a fire.

Basket | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Cap., gal. | OD | O'all Ht. | Material | Specifications Met | OD | Ht. | Mesh Opening Dia. | Material | Each | |

For Solvent-Based Solutions | ||||||||||

| 3 1/2 | 14" | 13" | Steel | FM Approved, UL Listed | 12 1/2" | 4 1/2" | 0.094" | Steel | 0000000 | 0000000 |

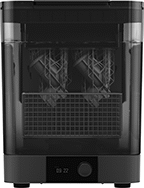

Automated 3D-Printed-Parts Washers

Remove sticky excess resin from 3D-printed parts hands-free. Just fill these washers with isopropyl alcohol or another solvent and choose your resin’s wash time. In minutes, your parts will be clean. No need for time-consuming hand washing—an impeller automatically churns the solvent to get resin out of shallow holes and internal channels on your parts. Once washing is done, air- or fan-dry before curing.

If your parts were printed with a Formlabs printer, you don’t have to remove your parts from the build platform. Slot the full platform into these washers and you’re ready to go. To prevent your parts from warping, they’ll automatically lift the platform out of the solvent once washing stops.

Washing solutions remove nearly twice as much resin as isopropyl alcohol before having to be replaced. They’re safe for use in any workspace. However, you shouldn’t use them with flexible resins or flame-retardant resins. After use, you’ll need to soak your parts in water to prevent swelling.

Washing solution pumps let you fill and empty the wash tub without spilling any solvent.

For Max. Part | O'all | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., gal. | Lg. | Wd. | Ht. | Lg. | Wd. | Ht. | Voltage | Material | Electrical Connection Type | Includes | Each | |

| 3 1/2 | 7 7/8" | 5 5/8" | 7 1/2" | 12 3/8" | 11 1/2" | 15 7/8" | 120V AC/240V AC | Plastic | Plug | Adjustable Mounting Feet, Density Meter, Wash Tub | 0000000 | 0000000 |

Container | ||||||

|---|---|---|---|---|---|---|

| Size, gal. | Type | Material | Composition | Mixing Required | Each | |

| 1.3 | Jug | Plastic | Solvent Based | No | 0000000 | 000000 |

Intake Tube | |||||||

|---|---|---|---|---|---|---|---|

| OD | Lg. | Material | Discharge Location | Batteries Included | Voltage | Each | |

| 1 3/8" | 13 3/4" | HDPE Plastic | Tube and Nozzle | No | 3V DC | 0000000 | 000000 |