Drain Pans

A handle and pour spout make it easy to transport and discard contents.

Styles A and D have a storage compartment where fluids drain for disposal later.

Wheels | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Capacity, gal. | Lg. | Wd. | Ht. | Material | Color | Autoclavable | Max. Temp. | No. of | Dia. | Includes | Each | |

| D | 15 | 39" | 24 1/8" | 8 7/8" | Polyethylene Plastic | Black | No | Not Rated | 2 | 3" | Drain Plug, Spout Cap | 00000000 | 0000000 |

Rectangular Plastic Batch Cans

These batch cans come with loose fitting dust covers to protect contents from dust and debris.

Bottom Inside | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity, gal. | Wd. | Dp. | Ht. | Wd. | Dp. | Thick. | Color | Clarity | Lid Type | Max. Temp., °F | Space Saving Features | Features | Each | |

Polyethylene Plastic | ||||||||||||||

| 15 | 27 3/4" | 16" | 13 3/4" | 23" | 11 1/4" | 1/4" | White | Semi-Clear | Loose Fitting | 140° | Stackable | Seamless | 0000000 | 0000000 |

Rectangular Plastic Batch Cans with Faucet

A built-in faucet allows easy dispensing.

Bottom Inside | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., gal. | Wd. | Dp. | Ht. | Wd. | Dp. | Thick. | Color | Clarity | Lid Type | Faucet Material | Seal Material | Max. Temp., °F | Space Saving Features | Features | Each | |

Polyethylene Plastic | ||||||||||||||||

| 15 | 17 1/4" | 14" | 19" | 15 1/4" | 12" | 3/8" | White | Semi-Clear | Loose Fitting | Polyethylene Plastic | PTFE Plastic | 175° | Stackable | Seamless | 0000000 | 0000000 |

High-Temperature Rectangular Plastic Batch Cans

Bottom Inside | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity, gal. | Wd. | Dp. | Ht. | Wd. | Dp. | Thick. | Color | Clarity | Lid Type | Max. Temp., °F | Space Saving Features | Features | Each | |

Polypropylene Plastic | ||||||||||||||

| 15 | 20 3/4" | 15" | 20" | 18" | 12" | 1/4" | White | Semi-Clear | Loose Fitting | 220° | Stackable | Seamless | 0000000 | 0000000 |

Food Industry Round Metal Batch Cans

These metal batch cans meet NSF/ANSI 2 standards for food-processing equipment.

Round Plastic Batch Cans

| Capacity, gal. | Dia. | Ht. | Bottom ID | Thick. | Graduation Marks | Color | Clarity | Lid Type | Max. Temp., °F | Space Saving Features | Features | Each | |

Polyethylene Plastic | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 15 | 15" | 27 3/4" | 13 1/4" | 3/16" | 1 gal., 5 L | White | Semi-Clear | Loose Fitting | 140° | Stackable | Seamless | 0000000 | 0000000 |

High-Temperature Round Plastic Batch Cans

| Capacity, gal. | Dia. | Ht. | Bottom ID | Thick. | Graduation Marks | Color | Clarity | Lid Type | Max. Temp., °F | Space Saving Features | Features | Each | |

Polypropylene Plastic | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 15 | 14 3/4" | 27 3/4" | 13 1/4" | 3/16" | 1 gal., 5 L | White | Semi-Clear | Loose Fitting | 220° | Stackable | Seamless | 0000000 | 0000000 |

Plastic Drums

These drums are UN-compliant for shipping.

Note: In hot-fill applications, allow contents to cool to ambient temperature before stacking.

Openings | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., gal. | Wt. Cap., lbs. | Material | Dia. | Ht. | Thick. | Pipe/Thread Size | Gender | Number of Handles | Max. Temp., °F | Space Saving Features | Shipping Standard | Choose a Color | Each | |

| 15 | 235 | Polyethylene Plastic | 14 3/8" | 26 1/4" | 1/8" | 2 NPSM, 3/4 NPSM | Female | 1 | 150° | Stackable | UN1H1/Y1.9/100 | White | 000000 | 000000 |

| 15 | 250 | Polyethylene Plastic | 15 5/8" | 25 1/2" | 1/8" | M64 Metric, M64 Metric | Female | 2 | 150° | Stackable | UN1H1/X1.9/320 | Black | 000000 | 00000 |

| 15 | 250 | Polyethylene Plastic | 16" | 20 3/4" | 1/8" | 2 NPSM, M64 Metric | Female | 2 | 150° | Stackable | UN1H1/Y2.0/150 | 000000 | 00000 | |

Heavy Duty Plastic Drums

These drums are seamless, making them more durable than other plastic drums.

| Capacity, gal. | Weight Capacity, lbs. | Dia. | Ht. | Bottom ID | Thick. | Clarity | Seal Material | Closing Ring Material | Max. Temp., °F | Space Saving Features | Each | |

Polyethylene Plastic | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

White | ||||||||||||

| 15 | 150 | 17 7/8" | 22 1/2" | 15 1/4" | 3/16" | Semi-Clear | EPDM Rubber | Steel | 180° | Stackable | 0000000 | 000000 |

Openings | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity, gal. | Weight Capacity, lbs. | Dia. | Ht. | Thick. | Clarity | For Pipe Size | Gender | Max. Temp., °F | Space Saving Features | Includes | Each | |

Polyethylene Plastic | ||||||||||||

White | ||||||||||||

| 15 | 150 | 15 3/4" | 22 1/2" | 3/16" | Semi-Clear | 2 NPSM, 3/4 NPSM | Female | 180° | Stackable | Plastic Plugs | 0000000 | 000000 |

| For Drum Capacity, gal. | Lid Color | Each | |

| 15 | White | 00000000 | 000000 |

| For Drum Capacity, gal. | Closing Ring Material | Each | |

Leverlock Closing Ring | |||

|---|---|---|---|

| 15 | Steel | 00000000 | 000000 |

Fiber Drums

Store dry materials in these lightweight drums.

| Capacity, gal. | Weight Capacity, lbs. | Dia. | Ht. | Bottom ID | Color | Rim Material | Closing Ring Material | Max. Temp. | Space Saving Features | Each | |

Fiber | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 15 | 225 | 14 1/2" | 23 1/2" | 14" | Beige | Galvanized Steel | Steel | Not Rated | Stackable | 0000000 | 000000 |

Bottom Inside | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity, gal. | Weight Capacity, lbs. | Wd. | Dp. | Ht. | Wd. | Dp. | Color | Max. Temp. | Space Saving Features | Shipping Standard | Each | |

Fiber | ||||||||||||

| 15 | 225 | 15 1/2" | 15 1/2" | 16 1/2" | 14 1/2" | 14 1/2" | Beige | Not Rated | Stackable | UN1G/Y75/S | 00000000 | 000000 |

Rubber and Plastic Tubs

These tubs are crack and dent resistant.

| Style | Capacity, gal. | Dia. | Ht. | Bottom ID | Thick. | Max. Temp., °F | Space Saving Features | Color | Each | |

Rubber | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| A | 15 | 26" | 9 1/2" | 20" | 3/16" | 160° | Nestable | Black | 000000 | 000000 |

Plastic Waste Containers and Lids

Heavy Duty Plastic Waste Containers

Often used in high-traffic environments, such as parking lots and cafeterias, these waste containers are dent resistant. They are designed to extinguish internal fires.

Metal Waste Containers

Style C extinguish internal fires by restricting oxygen flow.

| Style | Capacity, gal. | Dia. | Ht. | Circumference | Material | Specifications Met | Color | Each | |

| C | 15 | 15 1/4" | 26" | 47" | Steel | FM Approved, UL Listed | Gray | 000000 | 0000000 |

Wall-Mount Waste Containers

Mount these containers to the wall to avoid using valuable floor space.

Style A are fire resistant.

Mounting | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Capacity, gal. | Wd. | Dp. | Ht. | Circumference | For Use Outdoors | Hardware Included | Number of Holes | Hole Dia. | Specifications Met | Features | Color | Each | |

Plastic | ||||||||||||||

| A | 15 | 19 1/2" | 12" | 32 1/2" | 63" | Yes | Yes | 2 | 9/32" | FM Approved | Bag-Securing Hooks | Beige | 0000000 | 0000000 |

Dual Compartment Step-Open Waste and Recycling Containers

Dispose of waste and recycling in a single container, while still keeping them separate—these containers open hands-free with their foot pedal and close softly. The recycling side has a removable blue liner with a handle, so it’s easy to remove and see which bin is for recycling. On the garbage side, a rim holds garbage bags in place; there’s no inner liner, which means there’s more room for trash. Store extra bags in the built-in garbage bag dispenser.

Made of stainless steel, these containers are durable and won’t rust from small spills. However, they’re recommended for indoor use only. Their surface has a protective finish that curbs the growth of bacteria, fungi, mold, and mildew, and also prevents smudges, leaving containers looking clean and shiny. The active ingredient in the protective finish is EPA registered.

One pack of garbage bags is included. The bags are made of thick plastic with double seams to prevent rips. Drawstring handles make them easy to lift, tie, and carry.

Wall-Mount Plastic Easy-Drain Tanks

These tanks are often used as gravity-fed dispensers.

Drain | Mounting Holes | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., gal. | Wd. | Dp. | Ht. | Thick. | Fill Opening Dia. | Grad. Marks | Color | Pipe Size | Gender | Bottom Slope Angle | Max. Temp., °F | No. of | Dia. | Mounting Fasteners Included | UV Protection | Includes | Each | |

Polyethylene Plastic | ||||||||||||||||||

| 15 | 16" | 16" | 23" | 1/4" | 8" | 1/2 gal. | White | 1 1/4 NPT | Female | 46° | 120° | 8 | 5/16" | No | UV Resistant | Vented Fill Cap | 0000000 | 0000000 |

| Replacement Polypropylene Plastic Fill Cap For 8" Fill Opening Dia. | 0000000 | Each | 000000 |

Plastic Easy-Drain Tanks

Optional Stand

with Mixer Mount

The seamless, heavy-wall construction makes these tanks durable and easy to clean. The bottom is sloped to ensure easy drainage.

Stands (sold separately) allow a 14 1/4" minimum clearance from the bottom of drain to the floor.

Plastic Spill-Control Pallets

These pallets have removable grating for easy cleaning.

| Style | For No. of 55-Gal. Drums | Cap., gal. | Weight Cap., lbs. | Lg. | Wd. | Ht. | Color | No. of Entry Points for Forklifts | Space Saving Features | Each | |

Polyethylene Plastic | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | 1 | 15 | 2,000 | 26 1/4" | 26" | 6 1/2" | Yellow | 4 | Stackable | 00000000 | 0000000 |

Collapsible Spill-Control Trays

A flexible alternative to spill-control pallets, these trays collapse when not in use for easy storage.

Style A have flexible sidewalls that spring back into shape. Drive over them to drop drums directly onto the mat.

Bottom Inside | Collapsed | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | For Number of 55-Gallon Drums | Capacity, gal. | Lg. | Wd. | Ht. | Lg. | Wd. | Color | Lg. | Wd. | Ht. | Features | Each | |

PVC-Coated Polyester Fabric | ||||||||||||||

| A | 2 | 15 | 54" | 30" | 3" | 48" | 24" | Yellow | 30" | 10" | 10" | Flexible Sidewalls | 0000000 | 0000000 |

Vacuum Containers

Also known as vacuum degassing chambers, these remove trapped air from mixtures such as paint and mold resins. The fittings on the hose contain a gasket that allows you to connect the hose to flared fittings.

Aluminum containers are lightweight, corrosion resistant, and good for general use.

Acrylic lids are more durable than glass lids. They’re commonly used to eliminate air bubbles in hard setting materials, such as silicone and polyurethane.

Replacement lids do not include hardware or seal.

Containers | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Gauge | Hose | Replacement Lids | |||||||||||||||||

| Cap. | Dia. | Ht. | Bottom ID | Vacuum Range, in. of Hg | Accuracy | Grad. Marks, in. of Hg | Lg. | Thread Size | Gender | For Connection Style | For Flared Angle | For Tube OD | Max. Temp., °F | Removes Particle Size Down To | Includes | Each | Each | ||

Aluminum with Top-Mount Gauge | |||||||||||||||||||

Acrylic Plastic Lid with Silicone Rubber Seal | |||||||||||||||||||

| 15 gal. | 16 3/4" | 18 1/2" | 16 1/8" | 0 to 30 | ±5% | 0.5 | 5 ft. | 7/16"-20 UNF | Female | Flared | 37°, 45° | 1/4" | 150° | 50 microns | 50 Micron Air Filter, Lid | 0000000 | 0000000 | 0000000 | 0000000 |

| Removes Particle Size Down To | Each | |

| 50 microns | 0000000 | 00000 |

Mobile Electric Sprayers

Wheel these electric-powered sprayers wherever needed to disinfect surfaces and equipment in bathrooms, schools, gyms, and worksites without any manual pumping. Their wheels won’t leave streaks on your floors and they have a brake to keep them in place. Fill these sprayers with liquid disinfectants that kill bacteria, viruses, and other germs that cause disease. But, do not use them with oil-based or flammable products. Check the liquid level in the semi-clear tank to know when it’s time to refill; a full tank should give about three and a half hours of run time. The wand is light enough to hold with only one hand, and the nozzle releases disinfectant as a fine mist to coat surfaces evenly. To disinfect hard-to-reach spots and access multiple areas without unplugging and moving these sprayers, they come with a 25 ft. long hose. They also have an inline strainer to prevent clogs.

Note: The material of the parts can affect a sprayer's compatibility with a chemical or solution. Make sure that all parts of the sprayer are suitable for your application.

| Cap., gal. | Ht. | Wd. | Dp. | Max. Flow Rate, gpm | Max. Operating Pressure, psi | Tank Material | Seal Material | Color | Hose Lg., ft. | Wand Lg. | Fill Opening Dia. | Graduation Marks | Cord Lg., ft. | Each | |

Mist Dispensing | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

120V AC—Three-Prong Plug | |||||||||||||||

| 15 | 34 1/2" | 18 1/4" | 33" | 0.07 | 50 | Polyethylene Plastic | Viton® Fluoroelastomer Rubber | Semi-Clear White | 25 | 9 1/4" | 6" | 5 gal. | 6 | 0000000 | 000000000 |

Parts Washers for Solvent-Based Solutions

Use these washers with solvent-based cleaning solutions that have a flash point above 105° F. Turn on the pump and solution will flow to the flexible metal spigot. A fusible link closes the cover in the event of a fire. Note: Do not use with flammable liquids.

Washer with hardwire electrical connection requires a NEMA 6-15 or compatible plug.

Washers with filter remove large particles to keep the solution cleaner longer.

Usable Tub | O'all | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., gal. | Max. Liquid Level | Lg. | Wd. | Ht. | Lg. | Wd. | Ht. | Voltage | Material | Electrical Connection Type | Specifications Met | Features | Each | ||

Soak/Spray | |||||||||||||||

| A | 15 | 4 1/2" | 29 1/2" | 21" | 16" | 36" | 22" | 39" | 120V AC | Steel | Plug | UL Listed | Flexible Spigot, Drain Plug, Safety Cover with Fusible Link, Two Bi-Level Parts Shelves, Filter | 0000000 | 000000000 |

Coolers

Fill these insulated coolers with ice packs or ice to keep contents cold.

Style F have wheels for easy transport.

Wheel | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Cap., qt. | Wt., lbs. | Wd. | Dp. | Ht. | Material | Color | Lid Color | No. of | Material | Dia. | Each | |

| F | 60 | 11 | 23" | 17 1/2" | 17 3/4" | Plastic | Blue | White | 2 | Plastic | 6" | 0000000 | 000000 |

ASME-Code Compressed Air Storage Tanks

These tanks have drain ports on the bottom to remove condensation. All other ports can be used as inlets or outlets in any configuration.

Tanks with mounting plate have a platform where you can secure motors, pumps, and other components.

Steel tanks are primed or powder coated for exterior corrosion resistance. Epoxy-lined steel tanks also resist interior corrosion that can result from moisture in your compressed air.

Stainless steel tanks are more corrosion resistant than steel tanks.

Safety regulations restrict sales to the listed jurisdictions/areas.

Note: Per ASME code, all tanks are water tested. Those made without a corrosion-resistant coating or material will have rust on the interior.

Ports | Overall | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., gal. | Max. Pressure, psi | Total No. of | Gender | Sizes | Lg. | Dia. | Ht. | Wall Thick. | Temp. Range, °F | Cannot Be Sold To | Each | |

Horizontal | ||||||||||||

Primed Steel | ||||||||||||

| 15 | 200 | 7 | Female | 1/2 NPT Port (1 ea.) 3/4 NPT Port (2 ea.) 1 NPT Port (1 ea.) 1 1/2 NPT Port (2 ea.) 1/2 NPT Drain Port (1 ea.) | 26 3/4" | 14" | 16" | 1/8" | -20° to 400° | __ | 0000000 | 0000000 |

Powder-Coated Steel | ||||||||||||

| 15 | 200 | 6 | Female | 1/2 NPT Port (3 ea.) 3/4 NPT Port (2 ea.) 1/4 NPT Drain Port (1 ea.) | 33 5/8" | 12" | 13" | 1/8" | -20° to 400° | __ | 0000000 | 000000 |

Epoxy-Lined Powder-Coated Steel | ||||||||||||

| 15 | 200 | 7 | Female | 1/2 NPT Port (1 ea.) 3/4 NPT Port (2 ea.) 1 1/2 NPT Port (3 ea.) 1/2 NPT Drain Port (1 ea.) | 26 3/4" | 14" | 16" | 1/8" | -20° to 400° | __ | 0000000 | 000000 |

316 Stainless Steel | ||||||||||||

| 15 | 200 | 7 | Female | 1/2 NPT Port (1 ea.) 3/4 NPT Port (2 ea.) 1 NPT Port (1 ea.) 1 1/2 NPT Port (2 ea.) 1/2 NPT Drain Port (1 ea.) | 28" | 14" | 16" | 1/8" | -20° to 450° | Canada | 0000000 | 00000000 |

Horizontal with Mounting Plate | ||||||||||||

Primed Steel | ||||||||||||

| 15 | 200 | 5 | Female | 3/4 NPT Port (1 ea.) 1 NPT Port (1 ea.) 1 1/2 NPT Port (2 ea.) 1/2 NPT Drain Port (1 ea.) | 26 3/4" | 14" | 17" | 1/8" | -20° to 400° | __ | 0000000 | 000000 |

Powder-Coated Steel | ||||||||||||

| 15 | 200 | 6 | Female | 1/2 NPT Port (3 ea.) 3/4 NPT Port (2 ea.) 1/4 NPT Drain Port (1 ea.) | 33 5/8" | 12" | 15" | 1/8" | -20° to 400° | __ | 0000000 | 000000 |

Vertical | ||||||||||||

Powder-Coated Steel | ||||||||||||

| 15 | 200 | 5 | Female | 3/4 NPT Port (4 ea.) 1/2 NPT Drain Port (1 ea.) | __ | 12" | 35" | 1/8" | -20° to 400° | __ | 000000 | 000000 |

High-Pressure ASME-Code Compressed Air Storage Tanks

Able to withstand pressures up to 600 psi, these tanks store compressed air for use in high-pressure applications. They’re made of steel that's primed to resist exterior corrosion. Tanks have drain ports on the bottom to remove condensation. All other ports can be used as inlets or outlets in any configuration. Safety regulations restrict sales to the listed jurisdictions/areas.

Note: Per ASME code, all tanks are water tested and will have rust on the interior.

Ports | Overall | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., gal. | Max. Pressure, psi | Total No. of | Gender | Sizes | Lg. | Dia. | Ht. | Wall Thick. | Temp. Range, °F | Specifications Met | Cannot Be Sold To | Each | |

Horizontal | |||||||||||||

Gray Primed Steel | |||||||||||||

| 15 | 600 | 5 | Female | 3/4 NPT Port (1 ea.) 1 NPT Port (1 ea.) 1 1/2 NPT Port (2 ea.) 1/2 NPT Drain Port (1 ea.) | 27 1/4" | 14" | 16" | 1/4" | -20° to 400° | ASME BPVC.VIII.1 | Canada | 0000000 | 000000000 |

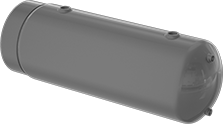

Expansion Tanks for Water

Use these tanks to accommodate the expansion of heated water and provide a cushion of compressed air in closed water-heating systems. They prevent water loss by eliminating the need to expel hot water from systems during each heating cycle.

Galvanized steel tanks are hot-dipped for maximum corrosion resistance.

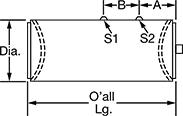

Tank Side Connection Pipe Size | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity, gal. | Dia. | Overall Lg. | Lg. (A) | Lg. (B) | (S1) | (S2) | Pipe Connection Thread Type | Pipe Connection Gender | Wall Gauge, ga. | Max. Temp., °F | Max. Pressure, psi | Expansion Tank Type | Each | |

| 15 | 12" | 30" | 4" | 11" | 1/2 | 1/2 | NPT | Female | 14 | 450° | 75 | Bladderless | 000000 | 0000000 |

--2f436187df31610558284-p9@halfx_637461338101519682.png?ver=imagenotfound)

-1610456742-p9@halfx_637460319512142470.png?ver=imagenotfound)

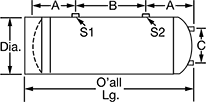

Tank End Connection Pipe Size | Tank Side Connection Pipe Size | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity, gal. | Dia. | Overall Lg. | Lg. (A) | Lg. (B) | Lg. (C) | (E1) | (E2) | (E3) | (S1) | (S2) | (S3) | Pipe Connection Thread Type | Pipe Connection Gender | Wall Gauge, ga. | Max. Temp., °F | Max. Pressure, psi | Expansion Tank Type | Each | |

| 15 | 12" | 33" | 4" | 11" | 8 13/16" | 1/2 | 1/2 | 2 | 1 1/4 | 1/2 | 1/2 | NPT | Female | 14 | 450° | 75 | Bladderless | 0000000 | 0000000 |

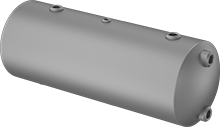

ASME-Code Expansion Tanks for Water

--7cc059f10c41610560320-p9@halfx_637461359604633535.png?ver=imagenotfound)

Manufactured in accordance with ASME BPVC.VIII.1, these tanks accommodate the expansion of heated water and provide a cushion of compressed air in closed water-heating systems. They prevent water loss by eliminating the need to expel hot water from systems during each heating cycle.

Tank End Connection Pipe Size | Tank Side Connection Pipe Size | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity, gal. | Dia. | Overall Lg. | Lg. (A) | Lg. (B) | Lg. (C) | (E1) | (E2) | (S1) | (S2) | Pipe Connection Thread Type | Pipe Connection Gender | Wall Gauge, ga. | Max. Temp., °F | Max. Pressure, psi | Expansion Tank Type | Each | |

Gray-Painted Steel | |||||||||||||||||

| 15 | 12" | 34 1/4" | 7" | 19" | 8" | 1/2 | 1/2 | 1 | 1 | NPT | Female | 13 | 450° | 150 | Bladderless | 00000000 | 0000000 |

Pressure-Rated Water Tanks

--7b4402cf881609347062-p9@halfx_637449222773319180.png?ver=imagenotfound)

--54972b9c0e11610558274-p9@halfx_637461335915238114.png?ver=imagenotfound)

These tanks can be used as water heaters when used with a heat source, such as an immersion heater. Also known as boiler tanks, they are designed to handle water pressure changes. Use them with hot or cold water. All are galvanized inside and outside for corrosion resistance.

Tank End Connection Pipe Size | Tank Side Connection Pipe Size | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity, gal. | Dia. | Overall Lg. | Lg. (A) | Lg. (B) | Lg. (C) | Lg. (D) | (E1) | (E2) | (S1) | (S2) | (S3) | (S4) | (S5) | Pipe Connection Thread Type | Pipe Connection Gender | Wall Gauge, ga. | Max. Temp., °F | Max. Pressure, psi | Each | |

Galvanized Steel | ||||||||||||||||||||

| 15 | 12" | 30" | 18" | 6" | 8" | 6" | 1 | 1 | 1 | 1 | 1 | 1 1/4 | 1/2 | NPT | Female | 14 | 450° | 75 | 0000000 | 0000000 |