Filter by

OD

Bearing Material

Flange OD

Width

Ball Material

For Use With

Weight Capacity

Length

Plain Bearing Type

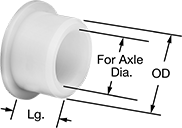

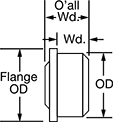

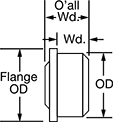

Conveyor Roller Ball Bearings

For Tubing

|  |  |  |  |

White Polypropylene | Black Polypropylene | Zinc-Plated Steel | Stainless Steel |

OD | Flange OD | Wt. Cap., lb. | Overall Wd. | Wd. | For Axle Shape | For Hex Axle Size | For Axle Dia. | Ball Material | Bearing Seal Type | Temp. Range, ° F | Features | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

White Polypropylene | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.600" | 1.800" | 45 | 0.80" | 0.60" | Hex | 7/16" | — | Stainless Steel | — | -10 to 140 | — | 60725K66 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.600" | 1.800" | 65 | 0.90" | 0.60" | Hex | 7/16" | — | Stainless Steel | — | -10 to 140 | — | 60725K67 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.800" | 1.900" | 45 | 1.20" | 1.00" | Hex | 7/16" | — | Stainless Steel | — | -10 to 140 | — | 60725K44 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.800" | 1.900" | 65 | 1.20" | 1.00" | Hex | 7/16" | — | Stainless Steel | — | -10 to 140 | — | 60725K65 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.900" | 2.000" | 45 | 0.80" | 0.60" | Hex | 7/16" | — | Stainless Steel | — | -10 to 140 | — | 60725K74 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.900" | 2.000" | 65 | 0.90" | 0.60" | Hex | 7/16" | — | Stainless Steel | — | -10 to 140 | — | 60725K75 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Polypropylene | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.270" | 1.375" | 300 | 0.60" | 0.40" | Round | — | 1/4" | Steel | Shielded | -10 to 140 | Quiet-Rolling Bearings | 6161T45 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.800" | 1.900" | 1,010 | 1.20" | 0.90" | Hex | 7/16" | — | Steel | Shielded | -10 to 140 | Quiet-Rolling Bearings | 6161T46 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.300" | 2.500" | 250 | 1.40" | 1.10" | Hex | 11/16" | — | Steel | Shielded | -10 to 140 | Quiet-Rolling Bearings | 6161T31 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.502" | 1.625" | 145 | 0.75" | 0.44" | Hex | 7/16" | — | Steel | — | -10 to 225 | — | 5907K11 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.712" | 1.812" | 300 | 0.69" | 0.39" | Hex | 7/16" | — | Steel | — | -10 to 225 | — | 5907K17 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.270" | 2.437" | 425 | 1.21" | 0.70" | Hex | 11/16" | — | Steel | — | -10 to 225 | — | 5907K13 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.270" | 2.437" | 425 | 1.23" | 0.74" | Hex | 11/16" | — | Steel | Shielded | -10 to 225 | — | 5907K15 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.502" | 1.625" | 145 | 0.75" | 0.44" | Hex | 7/16" | — | Stainless Steel | — | -10 to 300 | — | 5907K12 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.270" | 2.437" | 425 | 1.23" | 0.74" | Hex | 11/16" | — | Stainless Steel | — | -10 to 300 | — | 5907K14 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

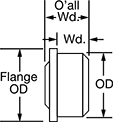

For Schedule 40 Pipe

|  |  |

White Polypropylene | Zinc-Plated Steel |

For Pipe Size | OD | Flange OD | Wt. Cap., lb. | Overall Wd. | Wd. | For Axle Shape | For Hex Axle Size | Ball Material | Bearing Seal Type | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

White Polypropylene | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 1.000" | 1.200" | 30 | 0.90" | 0.70" | Hex | 5/16" | Stainless Steel | — | -10 to 140 | 60725K61 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 | 1.600" | 1.800" | 45 | 0.80" | 0.60" | Hex | 7/16" | Stainless Steel | — | -10 to 140 | 60725K43 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 | 1.600" | 1.800" | 65 | 0.90" | 0.60" | Hex | 7/16" | Stainless Steel | — | -10 to 140 | 60725K64 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 2.100" | 2.300" | 60 | 0.80" | 0.60" | Hex | 7/16" | Stainless Steel | — | -10 to 140 | 60725K46 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 2.100" | 2.300" | 80 | 0.90" | 0.60" | Hex | 7/16" | Stainless Steel | — | -10 to 140 | 60725K76 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 3.066" | — | 600 | 1.25" | 1.00" | Hex | 1 1/16" | Steel | Shielded | -10 to 225 | 5907K16 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

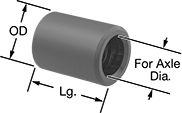

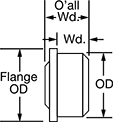

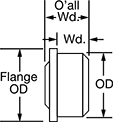

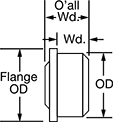

Conveyor Roller Sleeve Bearings

For Tubing

|  |

OD | Flange OD | Wt. Cap., lb. | Overall Wd. | Wd. | For Axle Shape | For Axle Dia. | Temp. Range, ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

White Acetal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.902" | 1.000" | 60 | 0.60" | 0.40" | Round | 1/4" | -40 to 180 | 60565K11 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.902" | 1.000" | 125 | 0.60" | 0.40" | Round | 1/2" | -40 to 180 | 60565K12 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.120" | 1.250" | 110 | 0.60" | 0.40" | Round | 3/8" | -40 to 180 | 60565K14 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.370" | 1.500" | 260 | 0.90" | 0.60" | Round | 5/8" | -40 to 180 | 60565K15 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.620" | 1.750" | 240 | 1.00" | 0.70" | Round | 1/2" | -40 to 180 | 60565K18 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.902" | 2.000" | 240 | 1.00" | 0.70" | Round | 1/2" | -40 to 180 | 60565K19 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.370" | 2.500" | 360 | 1.00" | 0.70" | Round | 3/4" | -40 to 180 | 60565K26 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.760" | 3.000" | 540 | 1.50" | 1.10" | Round | 3/4" | -40 to 180 | 60565K28 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

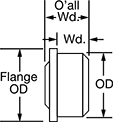

For Schedule 40 Pipe

|  |

For Pipe Size | OD | Flange OD | Wt. Cap., lb. | Overall Wd. | Wd. | For Axle Shape | For Axle Dia. | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

White Acetal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 1.049" | 1.300" | 110 | 0.60" | 0.40" | Round | 3/8" | -40 to 180 | 60565K13 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 | 1.610" | 1.900" | 240 | 1.00" | 0.70" | Round | 1/2" | -40 to 180 | 60565K17 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 2.067" | 2.400" | 110 | 1.00" | 0.70" | Round | 3/8" | -40 to 180 | 60565K21 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 2.067" | 2.400" | 240 | 1.00" | 0.70" | Round | 1/2" | -40 to 180 | 60565K22 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2 | 2.469" | 2.900" | 240 | 1.00" | 0.70" | Round | 1/2" | -40 to 180 | 60565K27 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Schedule 80 Pipe

|  |

For Pipe Size | OD | Flange OD | Wt. Cap., lb. | Overall Wd. | Wd. | For Axle Shape | For Axle Dia. | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

White Acetal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 | 1.500" | 1.900" | 240 | 1.00" | 0.70" | Round | 1/2" | -40 to 180 | 60565K16 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For EMT Conduit

|  |

For EMT Conduit Trade Size | OD | Flange OD | Wt. Cap., lb. | Overall Wd. | Wd. | For Axle Shape | For Axle Dia. | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

White Acetal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 2.067" | 2.200" | 300 | 1.00" | 0.70" | Round | 5/8" | -40 to 180 | 60565K23 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Conveyor Belt Take-Up Bearings

For Shaft Dia. | Dynamic Load Cap., lb. | Max. Rotation Speed, rpm | Lg. | Wd. | Ht. | Temp. Range, ° F | Features | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Iron | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 2,100 | 7,500 | 3 11/16" | 17/32" | 3 1/2" | -20 to 200 | Grease Fitting, Locking Collar with Two Set Screws | 6029K61 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 2,100 | 7,500 | 3 11/16" | 17/32" | 3 1/2" | -20 to 200 | Grease Fitting, Locking Collar with Two Set Screws | 6029K62 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 2,610 | 6,500 | 4" | 17/32" | 3 1/2" | -20 to 200 | Grease Fitting, Locking Collar with Two Set Screws | 6029K22 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 2,800 | 5,500 | 4 3/32" | 17/32" | 3 1/2" | -20 to 200 | Grease Fitting, Locking Collar with Two Set Screws | 6029K25 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/16" | 4,380 | 4,500 | 4 5/8" | 17/32" | 4" | -20 to 200 | Grease Fitting, Locking Collar with Two Set Screws | 6029K27 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 5,780 | 4,000 | 5" | 17/32" | 4" | -20 to 200 | Grease Fitting, Locking Collar with Two Set Screws | 6029K28 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 7/16" | 5,780 | 4,000 | 5" | 17/32" | 4" | -20 to 200 | Grease Fitting, Locking Collar with Two Set Screws | 6029K31 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 7,340 | 3,500 | 5 19/32" | 11/16" | 4 1/2" | -20 to 200 | Grease Fitting, Locking Collar with Two Set Screws | 6029K32 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | 7,900 | 3,000 | 5 17/32" | 11/16" | 4 3/4" | -20 to 200 | Grease Fitting, Locking Collar with Two Set Screws | 6029K33 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 15/16" | 7,880 | 3,000 | 5 29/32" | 11/16" | 4 1/2" | -20 to 200 | Grease Fitting, Locking Collar with Two Set Screws | 6029K36 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stainless Steel with Plastic Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 2,435 | 4,835 | 3 11/16" | 17/64" | 3 1/8" | 0 to 150 | Grease Fitting, Locking Collar with Two Set Screws | 6029K11 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 2,435 | 4,835 | 3 11/16" | 17/64" | 3 1/8" | 0 to 150 | Grease Fitting, Locking Collar with Two Set Screws | 6029K12 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | 2,650 | 4,610 | 3 13/16" | 17/64" | 3 1/8" | 0 to 150 | Grease Fitting, Locking Collar with Two Set Screws | 6029K13 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 2,650 | 4,610 | 3 13/16" | 17/64" | 3 1/8" | 0 to 150 | Grease Fitting, Locking Collar with Two Set Screws | 6029K14 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Conveyor Roller Ball Bearings with Axle

For Tubing

|  |

Black Polypropylene |

OD | Flange OD | Wt. Cap., lb. | Overall Wd. | Wd. | Axle Shape | Hex Axle Size | Ball Material | Bearing Seal Type | Temp. Range, ° F | Features | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Black Polypropylene | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.760" | 1.820" | 1,030 | 2.60" | 2.10" | Hex | 7/16" | Steel | Shielded | -10 to 140 | Quiet-Rolling Bearings | 6161T61 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

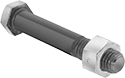

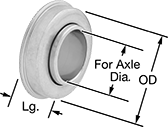

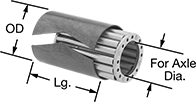

Wheel Bearings

Steel

|

Ball Bearings |

|

Roller Bearings |

For Axle Dia. | OD | Lg. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ball Bearings | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 1 1/8" | 7/8" | 23775T2 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 1 1/8" | 7/16" | 23775T4 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 1 3/16" | 15/16" | 23775T5 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 1 3/8" | 3/8" | 23775T6 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 1 3/8" | 3/8" | 23775T7 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Roller Bearings | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 15/16" | 1 1/4" | 25015T24 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 1 1/16" | 1 1/8" | 25015T11 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 1 3/16" | 1 3/8" | 25015T12 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 1 3/16" | 1 3/4" | 25015T25 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 1 3/16" | 1 7/8" | 25015T14 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 1 3/16" | 2" | 25015T26 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 1 3/16" | 1 1/4" | 25015T13 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 1 3/16" | 1 3/4" | 25015T27 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 1 3/16" | 1 7/8" | 25015T15 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 1 3/16" | 2" | 25015T33 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 1 3/16" | 2 1/2" | 25015T17 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | 1 7/16" | 2" | 25015T37 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1 7/16" | 2" | 25015T39 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1 7/16" | 2 1/2" | 25015T42 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1 9/16" | 2 1/4" | 25015T43 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1 15/16" | 2 1/2" | 25015T18 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1 15/16" | 3" | 25015T21 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 1 15/16" | 2 1/2" | 25015T47 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 1 15/16" | 3" | 25015T22 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 2 7/16" | 3" | 25015T73 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

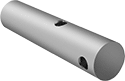

Screw Conveyors

Screws

|

Screw Dia. | Lg. | Edge Thk. | Shaft Dia. | Pitch | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 118 1/2" | 3/16" | 1" | 4" | 5866K521 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 118" | 1/16" | 1 1/2" | 6" | 5866K21 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9" | 118" | 3/16" | 1 1/2" | 9" | 5866K24 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9" | 118" | 3/16" | 2" | 9" | 5866K25 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 141" | 3/16" | 2 7/16" | 12" | 5866K27 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 142" | 3/16" | 2" | 12" | 5866K26 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 14" | 141" | 1/8" | 2 7/16" | 14" | 5866K28 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 118 1/2" | 3/16" | 1" | 4" | 5866K518 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 118" | — | 1 1/2" | 6" | 5866K881 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9" | 118" | — | 1 1/2" | 9" | 5866K882 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9" | 118" | 3/16" | 2" | 9" | 5866K519 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 141" | 3/16" | 2 7/16" | 12" | 5866K516 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 142" | — | 2" | 12" | 5866K883 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 14" | 141" | 3/16" | 2 7/16" | 14" | 5866K517 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Trough Covers

|

For Screw Dia. | Lg., ft. | For Shaft Dia. | Includes | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 10 | — | — | 5866K501 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 10 | — | 10 Cover Clamps, Rubber Seal | 5866K64 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9" | 10 | — | 10 Cover Clamps, Rubber Seal | 5866K65 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 12 | — | 10 Cover Clamps, Rubber Seal | 5866K67 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 14" | 12 | — | 10 Cover Clamps, Rubber Seal | 5866K68 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 10 | — | — | 5866K503 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 10 | — | — | 5866K504 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9" | 10 | 2" | — | 5866K891 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 12 | 2" | — | 5866K892 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 14" | 12 | — | — | 5866K502 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Trough Ends

|

For Screw Dia. | For Shaft Dia. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 1" | 5866K533 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 1 1/2" | 5866K11 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9" | 1 1/2" | 5866K12 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9" | 2" | 5866K13 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 2" | 5866K14 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 2 7/16" | 5866K15 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 14" | 2 7/16" | 5866K16 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 1" | 5866K531 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 1 1/2" | 5866K898 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9" | 1 1/2" | 5866K899 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9" | 2" | 5866K911 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 2" | 5866K912 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 2 7/16" | 5866K913 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 14" | 2 7/16" | 5866K529 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bearing Hangers

|

For Screw Dia. | For Shaft Dia. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 1" | 5866K532 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 1 1/2" | 5866K31 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9" | 1 1/2" | 5866K32 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9" | 2" | 5866K76 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 2" | 5866K34 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 2 7/16" | 5866K77 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 14" | 2 7/16" | 5866K78 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 1" | 5866K528 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 1 1/2" | 5866K893 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9" | 1 1/2" | 5866K894 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9" | 2" | 5866K895 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 2" | 5866K896 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 2 7/16" | 5866K897 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 14" | 2 7/16" | 5866K505 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bearings

|

For Screw Dia. | For Shaft Dia. | Max. Temp., ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Hardwood | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 1" | 150 | 5866K537 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6", 9" | 1 1/2" | — | 5914K44 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9", 12" | 2" | — | 5914K45 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12", 14" | 2 7/16" | — | 5914K61 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Polyethylene | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 1" | 225 | 5866K534 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

UHMW Polyethylene (FDA Compliant 21 CFR 177.1520) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6", 9" | 1 1/2" | — | 5914K47 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9", 12" | 2" | — | 5914K48 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12", 14" | 2 7/16" | — | 5914K63 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Iron | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 1" | 500 | 5866K538 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6", 9" | 1 1/2" | — | 5914K71 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9", 12" | 2" | — | 5914K72 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12", 14" | 2 7/16" | — | 5914K73 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 1" | 225 | 5866K535 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6", 9" | 1 1/2" | 850 | 5914K35 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9", 12" | 2" | 850 | 5914K37 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9", 12" | 2 7/16" | 850 | 5866K536 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

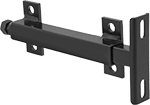

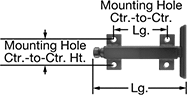

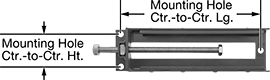

Conveyor Belt Take-Up Frames

|

|  |

Painted Steel | Stainless Steel |

Mounting Hole | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Adjustment Lg. | Lg. | Ht. | Adjusting Screw Material | Mounting Fasteners Included | Dia. | Ctr.-to-Ctr. Lg. | Ctr.-to-Ctr. Ht. | Color | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Painted Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 7" | 4 1/16" | Cadmium-Plated Steel | No | 9/16" | 6" | 3 3/16" | Gray | 6029K41 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 8 1/2" | 4 1/16" | Cadmium-Plated Steel | No | 9/16" | 7 1/2" | 3 3/16" | Gray | 6029K42 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 11 1/2" | 4 1/16" | Cadmium-Plated Steel | No | 9/16" | 10 1/2" | 3 3/16" | Gray | 6029K43 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 12 3/8" | 4 11/16" | Cadmium-Plated Steel | No | 9/16" | 11 3/8" | 3 11/16" | Gray | 6029K46 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 14" | 5 1/16" | Cadmium-Plated Steel | No | 9/16" | 12 7/8" | 3 1/16" | Gray | 6029K51 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9" | 14 1/2" | 4 1/16" | Cadmium-Plated Steel | No | 9/16" | 13 1/2" | 3 3/16" | Gray | 6029K44 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9" | 15 3/8" | 4 11/16" | Cadmium-Plated Steel | No | 9/16" | 14 3/8" | 3 11/16" | Gray | 6029K47 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9" | 17" | 5 1/16" | Cadmium-Plated Steel | No | 9/16" | 15 7/8" | 3 1/16" | Gray | 6029K52 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 18 3/8" | 4 11/16" | Cadmium-Plated Steel | No | 9/16" | 17 3/8" | 3 11/16" | Gray | 6029K48 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 20" | 5 1/16" | Cadmium-Plated Steel | No | 9/16" | 18 7/8" | 3 1/16" | Gray | 6029K53 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18" | 26" | 5 1/16" | Cadmium-Plated Steel | No | 9/16" | 24 7/8" | 3 1/16" | Gray | 6029K54 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 8" | 3 3/4" | Stainless Steel | No | 3/8" | 6 1/2" | 1 3/4" | — | 6029K56 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 11" | 3 3/4" | Stainless Steel | No | 3/8" | 9 1/2" | 1 3/4" | — | 6029K57 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9" | 14" | 3 3/4" | Stainless Steel | No | 3/8" | 12 1/2" | 1 3/4" | — | 6029K58 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 17" | 3 3/4" | Stainless Steel | No | 3/8" | 15 1/2" | 1 3/4" | — | 6029K59 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

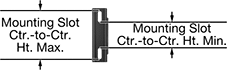

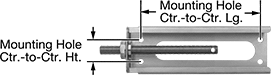

Enclosed Conveyor Belt Take-Up Frames

Mounting Hole | Mounting Slot | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Adjustment Lg. | Lg. | Ht. | Adjusting Screw Material | Mounting Fasteners Included | Dia. | Ctr.-to-Ctr. Lg. | Ctr.-to-Ctr. Ht. | Wd. | Ht. | Ctr.-to-Ctr. Ht. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 6 7/8" | 5 1/4" | Steel | No | 9/16" | 3 9/16" | 2 5/8" | 7/16" | 11/16" | 2 15/16" to 4 5/16" | 60085K11 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 8 1/2" | 7" | Steel | No | 9/16" | 4 3/8" | 3" | 9/16" | 15/16" | 3 13/16" to 5 11/16" | 60085K14 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 10 3/8" | 5 1/4" | Steel | No | 9/16" | 7 1/16" | 2 5/8" | 7/16" | 11/16" | 2 15/16" to 4 5/16" | 60085K12 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 11 1/2" | 7" | Steel | No | 9/16" | 7 3/8" | 3" | 9/16" | 15/16" | 3 13/16" to 5 11/16" | 60085K15 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9" | 14 3/8" | 5 1/4" | Steel | No | 9/16" | 11 1/16" | 2 5/8" | 7/16" | 11/16" | 2 15/16" to 4 5/16" | 60085K13 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9" | 14 1/2" | 7" | Steel | No | 9/16" | 10 3/8" | 3" | 9/16" | 15/16" | 3 13/16" to 5 11/16" | 60085K16 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 19 1/8" | 10" | Steel | No | 11/16" | 14 1/8" | 4" | 11/16" | 1 9/16" | 5 9/16" to 8 11/16" | 60085K19 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 6 7/8" | 5 1/4" | Stainless Steel | No | 9/16" | 3 9/16" | 2 5/8" | 7/16" | 11/16" | 2 15/16" to 4 5/16" | 60085K31 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 8 1/2" | 7" | Stainless Steel | No | 9/16" | 4 3/8" | 3" | 9/16" | 15/16" | 3 13/16" to 5 11/16" | 60085K34 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 10 3/8" | 5 1/4" | Stainless Steel | No | 9/16" | 7 1/16" | 2 5/8" | 7/16" | 11/16" | 2 15/16" to 4 5/16" | 60085K32 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 11 1/2" | 7" | Stainless Steel | No | 9/16" | 7 3/8" | 3" | 9/16" | 15/16" | 3 13/16" to 5 11/16" | 60085K35 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9" | 14 3/8" | 5 1/4" | Stainless Steel | No | 9/16" | 11 1/16" | 2 5/8" | 7/16" | 11/16" | 2 15/16" to 4 5/16" | 60085K33 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9" | 14 1/2" | 7" | Stainless Steel | No | 9/16" | 10 3/8" | 3" | 9/16" | 15/16" | 3 13/16" to 5 11/16" | 60085K36 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

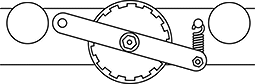

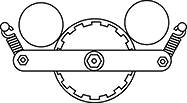

Speed Reducers for Roller Conveyors

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wt. Cap. | For Roller Dia. | For Roller Spacing Range | Lg. | Wd. | Ht. | Material | Wheel Material | Mounting Hardware Included | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Inline Mount | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 lb.-1,000 lb. | 1 3/8", 1.9", 2 1/2", 2 7/8" | 1" to 6" | 7 1/8" | 4" | 4 7/8" | Steel | Rubber-Coated Plastic | No | 8424T31 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1,000 lb.-3,000 lb. | 1 3/8", 1.9", 2 1/2", 2 7/8" | 1" to 6" | 7 1/8" | 4" | 4 7/8" | Steel | Rubber-Coated Plastic | No | 8424T32 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Under Mount | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 lb.-500 lb. | 1 3/8", 1.9", 2 1/2" | 2" to 4" | 7 3/8" | 4" | 4 3/4" | Steel | Rubber-Coated Plastic | Yes | 8424T12 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 175 lb.-1,800 lb. | 1 3/8", 1.9", 2 1/2" | 2" to 4" | 7 3/8" | 4" | 4 3/4" | Steel | Rubber-Coated Plastic | Yes | 8424T13 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 500 lb.-2,500 lb. | 1 3/8", 1.9", 2 1/2" | 2" to 4" | 7 3/8" | 4" | 4 3/4" | Steel | Rubber-Coated Plastic | Yes | 8424T14 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||