About Sizing Belts

More

Rough-Top Belting for Slider-Bed Conveyors

The textured surface grips packages and cartons to prevent material from slipping when traveling on inclines and declines. A low-friction bottom surface allows belting to glide along the bed of the conveyor. Use belting with hammer-on hook-style lacing or quick-install hook-style lacing.

Note: The top surface of the belt ends should be removed with a conveyor belt shaver or skiver before installing lacing. Recommended lacing is based on the thickness of the belt after removing the top surface.

SBR has good impact resistance and an excellent grip.

For Lace No. | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thick. | For Min. Pulley Dia. | Max. Belt Tension, PIW | Construction | Max. Temp., °F | Quick-Install Hook-Style | Hammer-On Hook-Style | 2" Wd. Per Ft. | 3" Wd. Per Ft. | 4" Wd. Per Ft. | 6" Wd. Per Ft. | 8" Wd. Per Ft. | 10" Wd. Per Ft. | 12" Wd. Per Ft. | 18" Wd. Per Ft. | 24" Wd. Per Ft. | |

Black SBR Rubber | ||||||||||||||||

| 0.250" | 2" | 150 | 2 Ply | 250° | 1 | 7 | 000000 | |||||||||

Beige SBR Rubber | ||||||||||||||||

| 0.265" | 3" | 200 | 3 Ply | 250° | 2 | 7 | 000000 | |||||||||

Belting for Roller-Bed Conveyors

This belting has a tough cover on the bottom to grip rollers.

SBR belting has a tough cover on the top and is excellent for abrasive and high-impact applications, including conveying stone, sand, and glass particles.

For Lace No. | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thick. | For Min. Pulley Dia. | Max. Belt Tension, PIW | Construction | Max. Temp., °F | Bolt-On Style | Rivet-Style | 2" Wd. Per Ft. | 4" Wd. Per Ft. | 6" Wd. Per Ft. | 8" Wd. Per Ft. | 10" Wd. Per Ft. | 12" Wd. Per Ft. | 18" Wd. Per Ft. | 24" Wd. Per Ft. | 30" Wd. Per Ft. | 36" Wd. Per Ft. | |

| 0.236" | 10" | 150 | 2 Ply | 200° | __ | R2 | 000000 | ||||||||||

| 0.360" | 10" | 220 | 2 Ply | 200° | 375X | __ | 000000 | ||||||||||

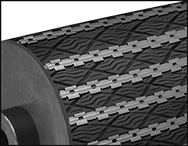

Retainer-Mount Coating for Conveyor Pulleys

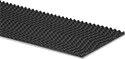

Slide these coating strips into metal retainers (sold separately) that you attach to your pulley—they add friction that helps conveyor belts stay on pulleys and are replaceable when they’re worn. Unlike traditional coatings, you don’t need to detach the pulley from your system to apply them. Each strip consists of rubber bonded to a metal backing plate to prevent it from separating from the pulley surface, which can happen to adhesive-mount coatings. When the strips wear out, pull them out and slide in new ones. They’re also known as lagging.

These rubber strips protect pulleys from wear and damage, helping them last longer. They have a diamond tread that sheds sand, gravel, grain, and other debris to prevent material buildup and maintain traction on the belt. Use them in dry and dirty environments.

Bolt or weld retainers onto the surface of your pulley. Single-sided retainers only have lock-down tabs on one side, so use them to mount the first and last strips. Double-sided retainers have lock-down tabs on both sides. Use them on the majority of your pulley’s diameter.

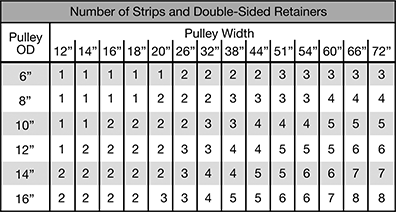

To Order: Check the chart or follow the 4 steps below to determine how many strips and retainers you’ll need to cover your pulley.

1. Divide the pulley’s diameter (in inches) by 2.

2. Multiply the answer by the pulley’s width, and then add 6.

3. Divide the answer from step 2 by 72 and round up. This is the number of strips and double-sided retainers you’ll need.

4. Take the answer from step 3 and divide it by 4, then round up. This is the number of single-sided retainers you’ll need.

Retainer-Mount Coating | Straight Profile |

|

| For Pulley Diameter | Length | Width | Thickness | Hardness | Hardness Rating | Temperature Range, °F | Each | |

SBR Rubber | ||||||||

|---|---|---|---|---|---|---|---|---|

| 6" | 72" | 5 1/2" | 9/16" | Durometer 60A | Soft | -50° to 225° | 0000000 | 0000000 |

| 8" | 72" | 5 1/2" | 9/16" | Durometer 60A | Soft | -50° to 225° | 0000000 | 000000 |

| 10" | 72" | 5 1/2" | 9/16" | Durometer 60A | Soft | -50° to 225° | 0000000 | 000000 |

| 12" | 72" | 5 1/2" | 9/16" | Durometer 60A | Soft | -50° to 225° | 0000000 | 000000 |

| 14" | 72" | 5 1/2" | 9/16" | Durometer 60A | Soft | -50° to 225° | 0000000 | 000000 |

| 16" | 72" | 5 1/2" | 9/16" | Durometer 60A | Soft | -50° to 225° | 0000000 | 000000 |

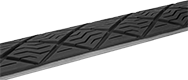

Super-Grip Flat Belting

Commonly used for material handling and light to medium duty power transmission, this belting has a textured rubber cover on both sides for gripping material. To join ends, use alligator belt lacing.

| Wd. | Wd. Tolerance | Material | Core Material | Color | For Min. Pulley Dia. | Per Ft. | |

Three Ply—0.141" Thick. | |||||||

|---|---|---|---|---|---|---|---|

| 1 1/4" | -0.125" to 0.125" | SBR Rubber | Cotton | Brown | 2 1/2" | 00000000 | 00000 |

| 1 1/2" | -0.125" to 0.125" | SBR Rubber | Cotton | Brown | 2 1/2" | 00000000 | 0000 |

| 2" | -0.125" to 0.125" | SBR Rubber | Cotton | Brown | 2 1/2" | 00000000 | 0000 |

| 2 1/2" | -0.125" to 0.125" | SBR Rubber | Cotton | Brown | 2 1/2" | 00000000 | 0000 |

| 3" | -0.125" to 0.125" | SBR Rubber | Cotton | Brown | 2 1/2" | 00000000 | 0000 |

| 4" | -0.125" to 0.125" | SBR Rubber | Cotton | Brown | 2 1/2" | 00000000 | 0000 |

| 6" | -0.125" to 0.125" | SBR Rubber | Cotton | Brown | 2 1/2" | 00000000 | 00000 |

Four Ply—0.187" Thick. | |||||||

| 1 1/4" | -0.125" to 0.125" | SBR Rubber | Cotton | Brown | 3" | 00000000 | 0000 |

| 1 1/2" | -0.125" to 0.125" | SBR Rubber | Cotton | Brown | 3" | 00000000 | 0000 |

| 2" | -0.125" to 0.125" | SBR Rubber | Cotton | Brown | 3" | 00000000 | 0000 |

| 2 1/2" | -0.125" to 0.125" | SBR Rubber | Cotton | Brown | 3" | 00000000 | 0000 |

| 3" | -0.125" to 0.125" | SBR Rubber | Cotton | Brown | 3" | 00000000 | 0000 |

| 4" | -0.125" to 0.125" | SBR Rubber | Cotton | Brown | 3" | 00000000 | 0000 |

| 6" | -0.125" to 0.125" | SBR Rubber | Cotton | Brown | 3" | 00000000 | 00000 |

Five Ply—0.213" Thick. | |||||||

| 1 1/4" | -0.125" to 0.125" | SBR Rubber | Cotton | Brown | 3 1/2" | 00000000 | 0000 |

| 1 1/2" | -0.125" to 0.125" | SBR Rubber | Cotton | Brown | 3 1/2" | 00000000 | 0000 |

| 2" | -0.125" to 0.125" | SBR Rubber | Cotton | Brown | 3 1/2" | 00000000 | 0000 |

| 2 1/2" | -0.125" to 0.125" | SBR Rubber | Cotton | Brown | 3 1/2" | 00000000 | 0000 |

| 3" | -0.125" to 0.125" | SBR Rubber | Cotton | Brown | 3 1/2" | 00000000 | 0000 |

| 4" | -0.125" to 0.125" | SBR Rubber | Cotton | Brown | 3 1/2" | 00000000 | 00000 |

| 6" | -0.125" to 0.125" | SBR Rubber | Cotton | Brown | 3 1/2" | 00000000 | 00000 |